Intelligent dust-free feeding and feeding all-in-one machine

A dust-free, all-in-one machine technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of high labor intensity and high risk, and achieve the effect of reducing production labor, low price and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

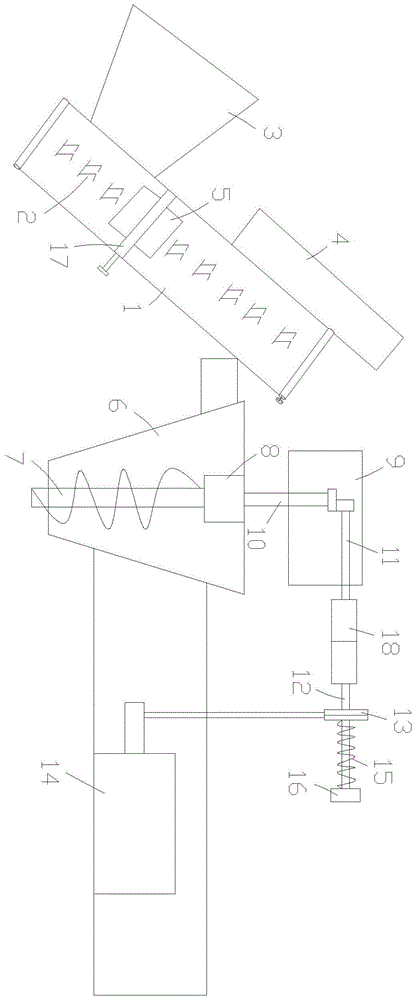

[0015] Such as figure 1 As shown, an intelligent dust-free feeding and feeding integrated machine includes a conveyor belt 1 arranged on the conveyor, and a material-moving hook 2 is arranged on the conveyor belt 1, and the material-moving hook 2 is fixed on the conveyor belt in a row 1, in order to transport crushed materials of various shapes and light weight, such as silk balls, irregular blocks, etc., the upper part of the conveyor belt 1 is connected with a collecting hopper 3, and the upper part of the other end is provided with a shroud 4, because of these The fluffy pulverized material is lighter in weight, and the shroud 4 plays a role in preventing the loss of the pulverized material during the transportation process. On the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com