Ultrasonic flaw detection robot for large spherical tank steel vessel

A technology for spherical tank steel and robots, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. It can solve problems such as heavy detection workload, low efficiency of manual detection, and danger. , to achieve high work efficiency, simple and convenient control, and avoid danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

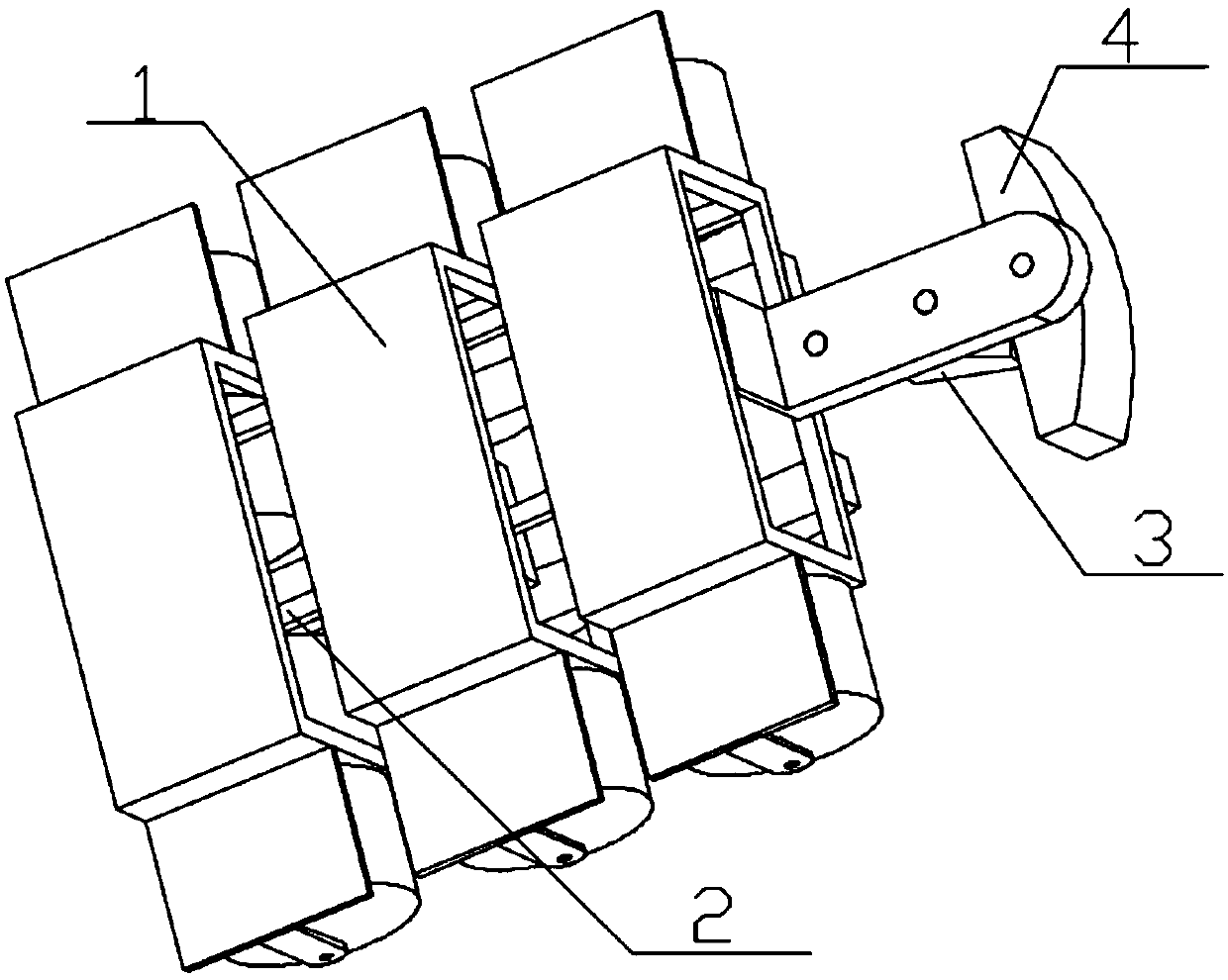

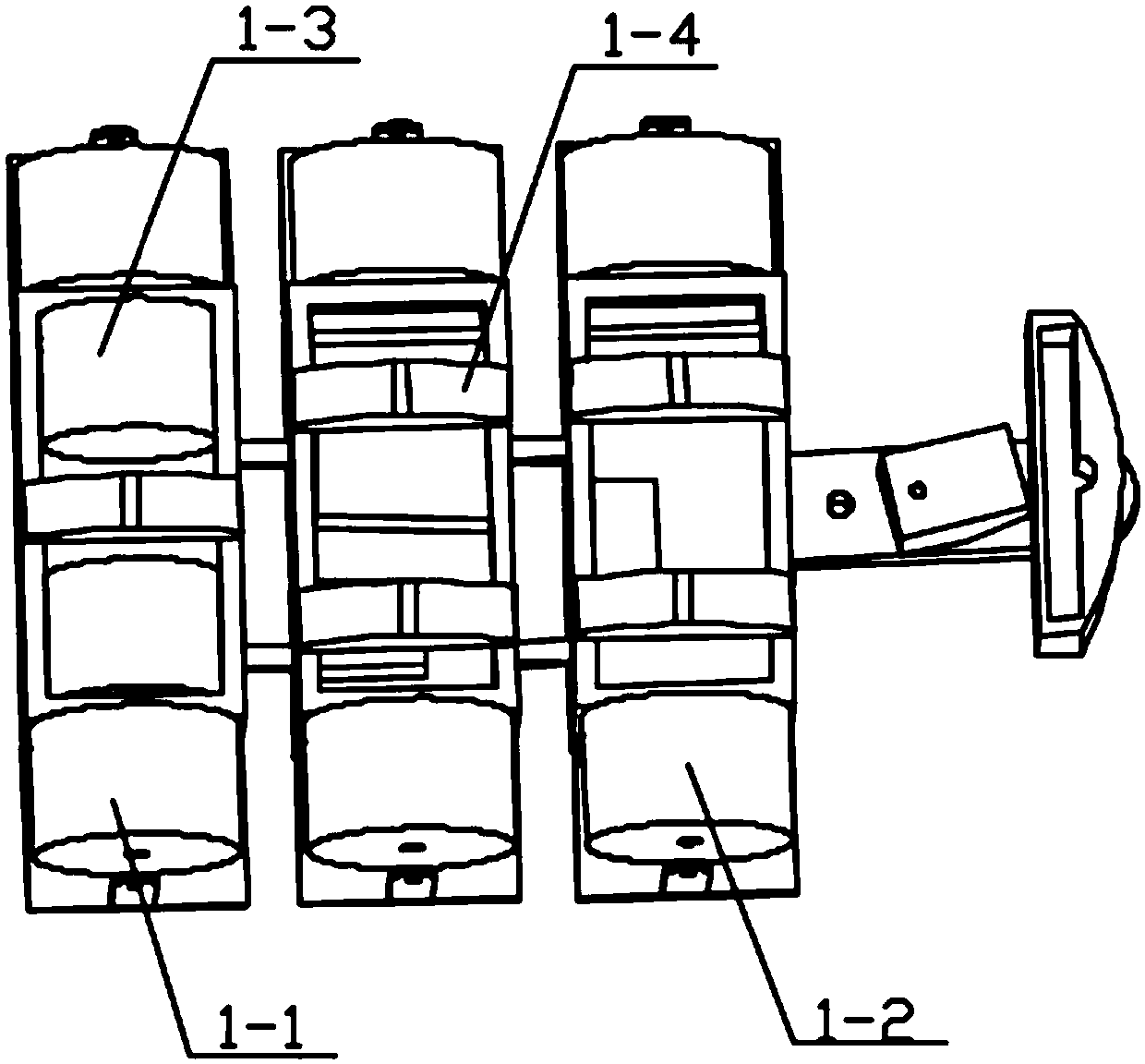

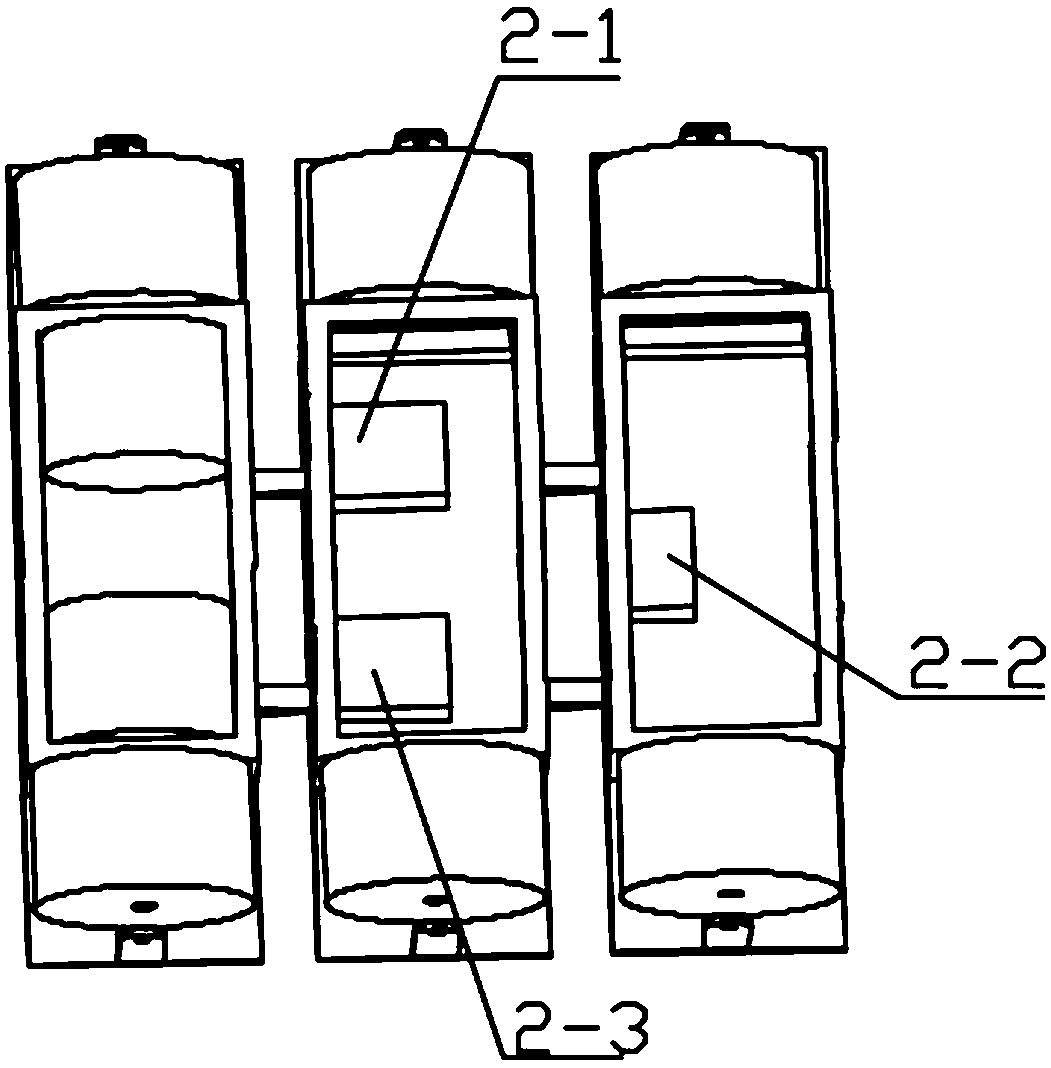

[0049] refer to figure 1 , an ultrasonic flaw detection robot for large spherical steel containers provided by the present invention includes a robot body, an image acquisition device, an adsorption device, a flaw detection device and a control system; the robot body includes a fuselage frame and an elastic connection structure, and the adsorption device Installed at the lower part of the fuselage, the flaw detection device is installed at the front of the fuselage, and the control system is installed inside the fuselage; the image acquisition device is an industrial camera, which is installed on the robot body, and is used to photograph the welding of the steel container wall of the spherical tank. seam, and the captured image is sent to the control system for processing to realize the function of seam tracing. The control system re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com