Threaded self-locking quick release device

A disengagement device and self-locking technology, which is applied in the field of threaded self-locking quick release devices, can solve the problems of complex safety, inconvenient, poor portability, etc., and achieve the effect of low cost, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

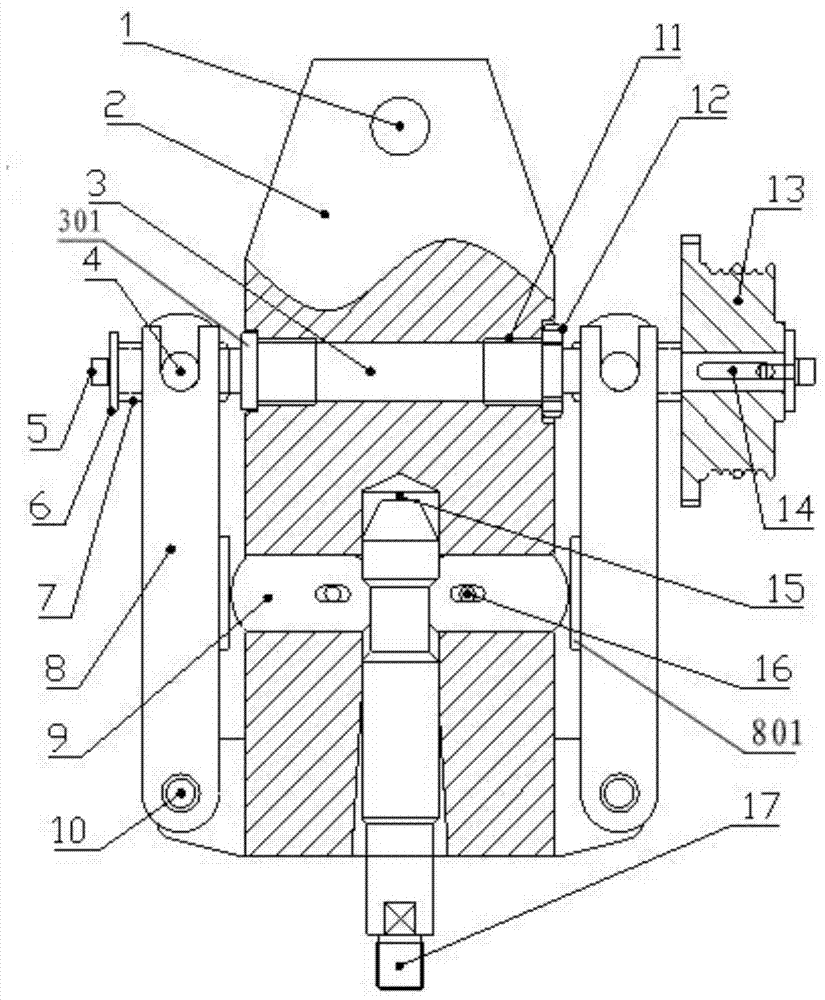

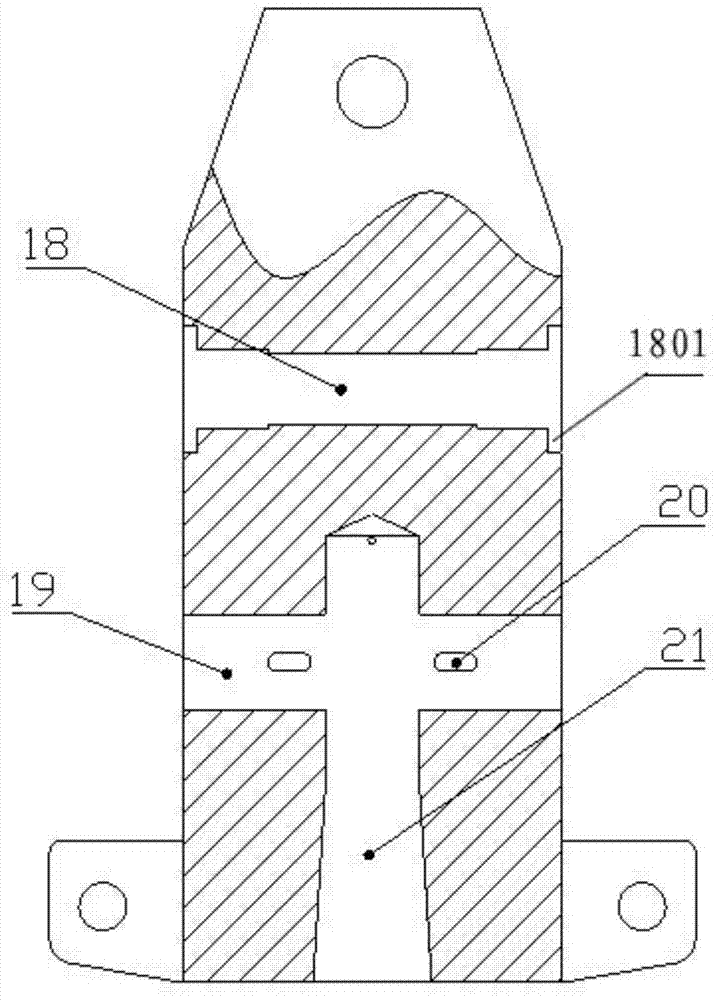

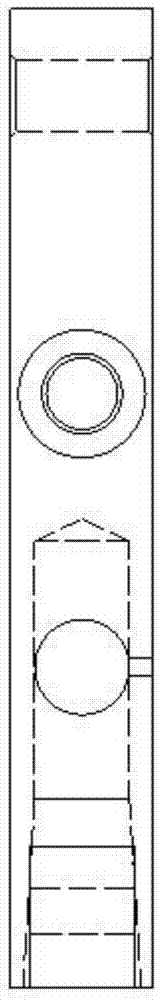

[0025] The threaded self-locking quick release device includes a lock body 2 and a lock head 17. The top of the lock body 2 is provided with a hoisting hole 1, and the bottom is provided with a vertical cavity 21 for inserting the lock head 17. The bottom of the vertical cavity 21 is The expanded shape of the horn is convenient for the lock head 17 to enter the vertical cavity 21 during automatic clamping; the lock head 17 is inserted in the vertical cavity 21 from bottom to top and a vent hole 15 is formed on the top of the vertical cavity 21, when the lock When the head 17 is inserted into or removed from the vertical cavity 21, positive pressure or negative pressure can be avoided.

[0026] The middle part of the lock body 2 is provided with a lower radial through hole 19 communicating with the vertical cavity 21, and the plug-in lock head 17 corresponding to the lower radial through hole 19 has a reduced diameter, and the lower radial through hole 19 is provided with a lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com