Compound moisturizing agent for foods and preparation method thereof

A humectant and food technology, which is applied in the field of food additives, can solve the problems of no compound food moisturizer and inconvenient production, and achieve the effects of promoting human health, improving safety, and good human tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

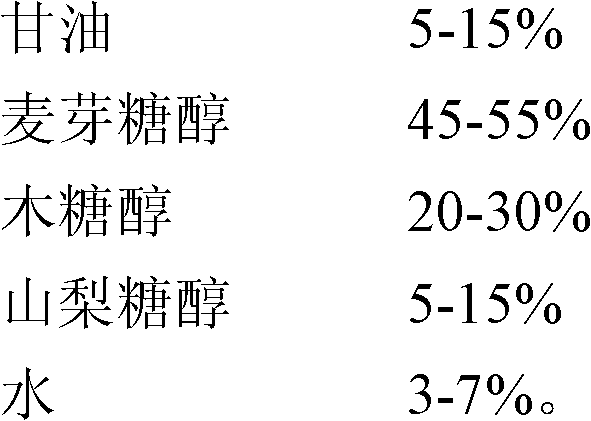

[0028] Based on the total weight of the final product, the weight and mass percentage of the solid material added is:

[0029]

[0030] The compound moisturizing agent is formulated according to the above, and the weight of each raw material is added in proportion according to the above proportion. To prepare 5 kg of product at a time, you need 300 grams of glycerin, 1400 grams of xylitol, 2500 grams of maltitol, and 550 grams of sorbitol.

[0031] The raw material of above-mentioned weight is made according to following process method:

[0032] (1) Put the weighed solid material xylitol, maltitol, sorbitol and mannitol into the dissolving tank to dissolve, the mass ratio of material and water is 1: 1, this example drops into 4450 grams of above-mentioned solid material altogether, add 4,450 grams of purified water was dissolved at a temperature of 90° C., heated by steam, and the stirring speed was 65 rpm until completely dissolved; then 300 grams of glycerin was added an...

Embodiment 2

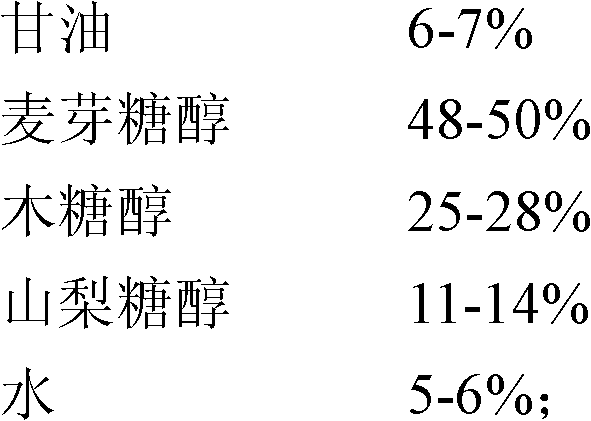

[0043] Based on the total weight of the final product, the weight and mass percentage of the solid material added is:

[0044]

[0045] The compound moisturizing agent is formulated according to the above, and the weight of each raw material is added in proportion according to the above proportion. A total of 1.5 tons of products are prepared. According to the ratio in the formula, the required raw materials are: 105 kg of glycerin, 375 kg of xylitol, 720 kg of maltitol, and 210 kg of sorbitol.

[0046] The raw material of above-mentioned weight is made according to following process method:

[0047] (1) putting weighed solid material xylitol, maltitol, sorbitol and mannitol into dissolving tank and dissolving, the mass ratio of material and water is 1.63: 1, and the present embodiment drops into 1304 kilograms of above-mentioned solid materials altogether, Add 800kg of purified water for dissolution, the dissolution temperature is 95°C, heat with steam, and the stirring s...

Embodiment 3

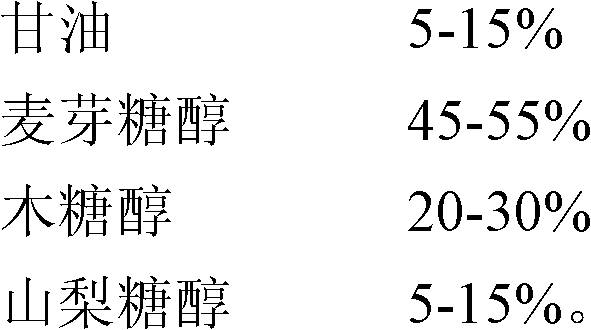

[0052] Based on the total weight of the final product, the weight and mass percentage of the solid material added is:

[0053]

[0054] The compound moisturizing agent is formulated according to the above, and the weight of each raw material is added in proportion according to the above proportion. A total of 100 kilograms of products are prepared. According to the ratio in the formula, the required raw materials are: 15 kilograms of glycerin, 20 kilograms of xylitol, 54 kilograms of maltitol, and 8 kilograms of sorbitol.

[0055] The raw material of above-mentioned weight is made according to following process method:

[0056] (1) Put the weighed solid material xylitol, maltitol, sorbitol and mannitol into the dissolving tank and dissolve, the mass ratio of material and water is 2: 1, this example drops into 82 kilograms of above-mentioned solid materials altogether, add Dissolve 41 kg of purified water at a temperature of 100°C, heat with steam, and stir at a speed of 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com