Free-wheel cage ring with centrifugal-force lifting

A technology of one-way clutches and cages, which is applied to one-way clutches, clutches, mechanical equipment, etc., can solve the problems of dangerous one-way clutch failures for operators, effects that affect functionality, unevenness, etc., and achieve accurate and firm guidance Surface configuration, simplified manufacturing process, and improved positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

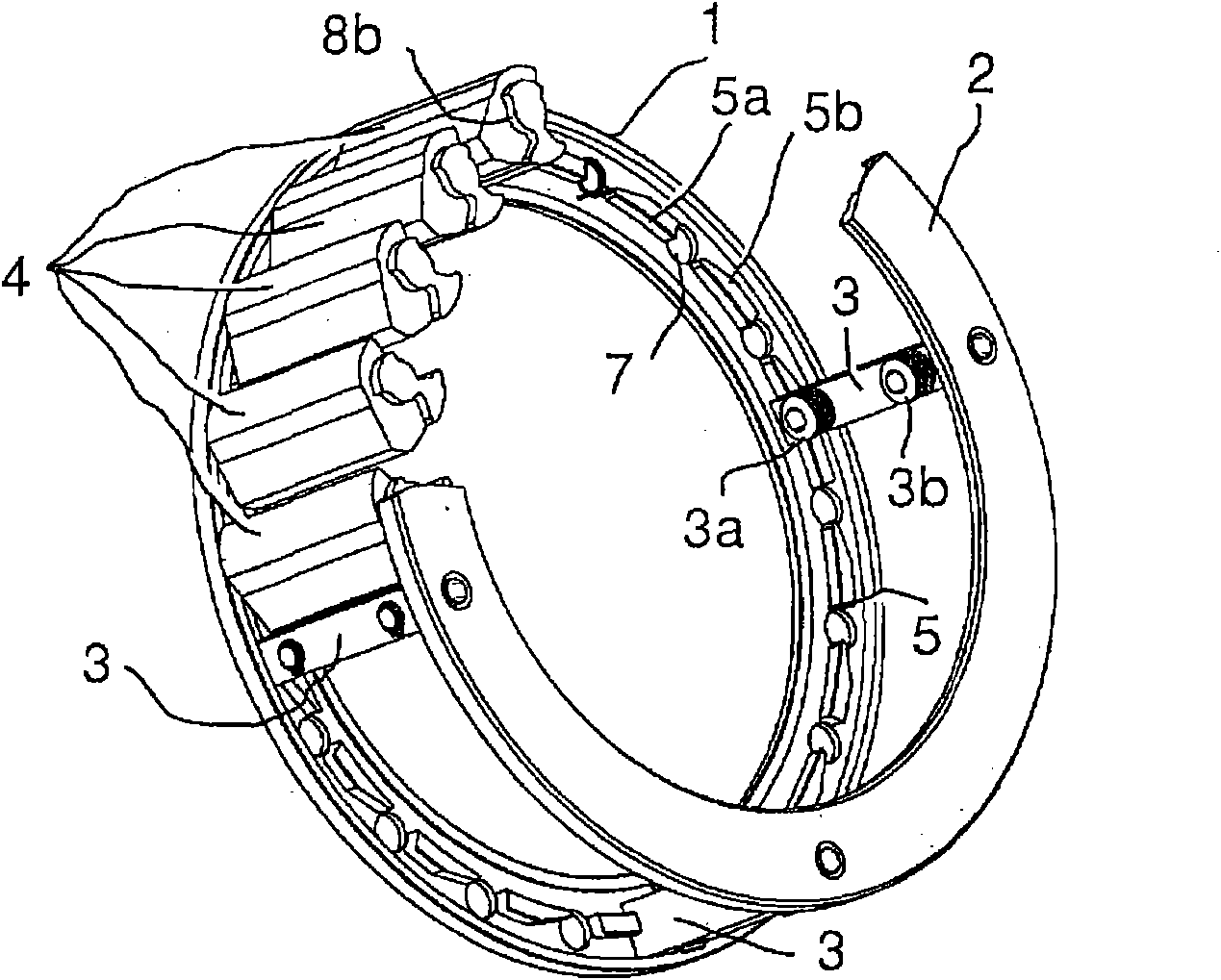

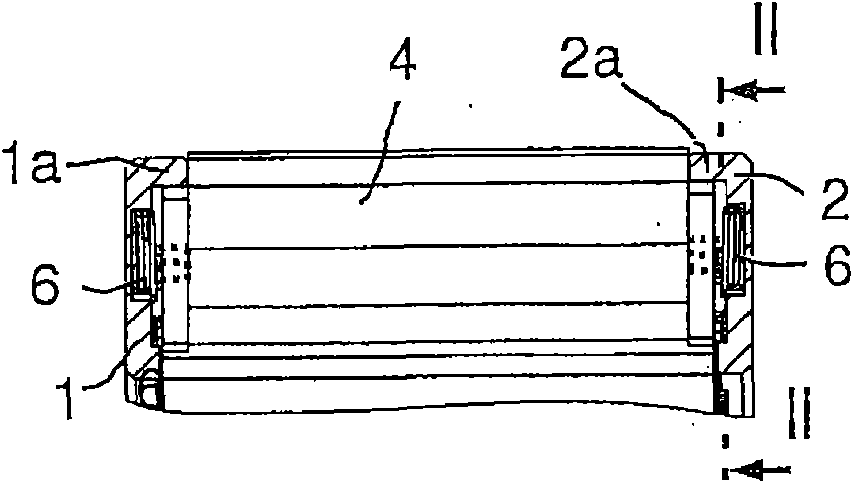

[0043] Figure 1 to Figure 5 A first embodiment of the one-way clutch cage according to the present invention is shown. The two annular end pieces 1 and 2 are connected to each other in parallel and concentrically by a plurality of axially extending connecting pins 3 . Each connecting pin 3 comprises two spring-loaded friction heads 3a, 3b for synchronizing the cage with the inner ring of the one-way clutch (not shown).

[0044] A plurality of action bodies 4 are arranged between (two) end pieces, figure 1 For the sake of clarity, only the active body in the upper left quarter of the one-way clutch cage is shown.

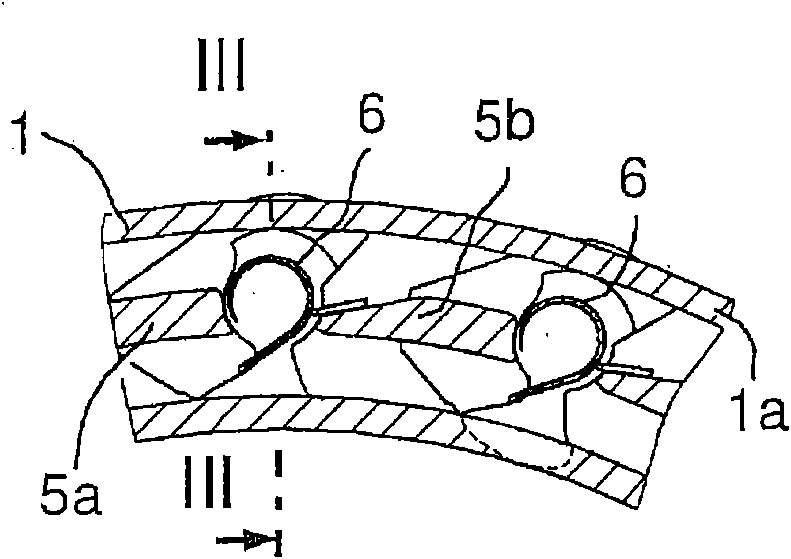

[0045] On the end sides facing each other, the end pieces each have a concentric flange 5 which is interrupted by a notch for forming the guide surface. For example, in figure 1 , 2 The two remaining webs 5 a and 5 b of the flange 5 are shown in and 4 . Guide surfaces are formed between the tabs by notches ( Figure 4 In 5c and 5d), the guide surface guides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com