Adjustable cutting-depth cutter bar

An adjustable and tool holder technology, which is applied to the accessories of tool holders, tool holders, turning equipment, etc., can solve the problems of low work efficiency and waste of resources, and achieve the effect of simple structure and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

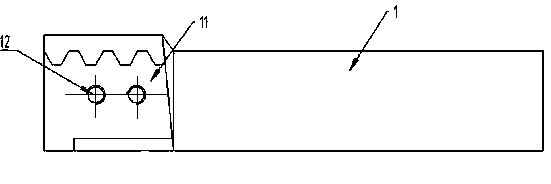

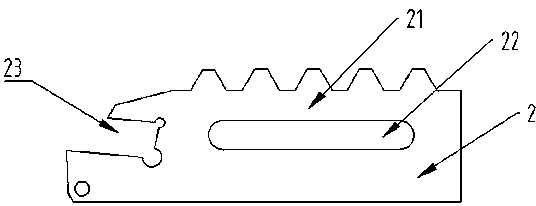

[0020] Such as Figure 4 with Figure 7 As shown, the present invention includes a rod-shaped knife handle 1 connected with a cutter head holder 2 .

[0021] The rod-shaped handle 1 is connected to the cutter head holder 2, which means that the rod-shaped handle 1 and the cutter head holder 2 are fixedly connected through the toothed groove 11 and the toothed bar 21 that cooperate with each other; the toothed groove 11 And the toothed bar 21 can be moved and adjusted to the required length.

[0022] Such as figure 1 with figure 2 As shown, the teeth of the cooperating toothed bar 11 and the toothed groove 21 are arranged on one side of the rod-shaped handle 1 and the bit holder 2 .

[0023] Such as Figure 5 with Image 6 As shown, the cooperating toothed grooves 11 and the teeth of the toothed bar 21 are arranged on both sides of the rod-shaped tool handle 1 and the tool bit holder 2 .

[0024] The tooth shape described is trapezoidal tooth, and other tooth shapes suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com