Method and apparatus for processing surface of ceramic polished brick

A processing method and technology of processing devices, applied in metal processing equipment, grinding/polishing equipment, machine tools with surface polishing, etc., can solve the problems of unreasonable process matching, low processing efficiency, poor product quality, etc., and improve product quality. The effect of improving the quality, product qualification rate and reducing the return rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

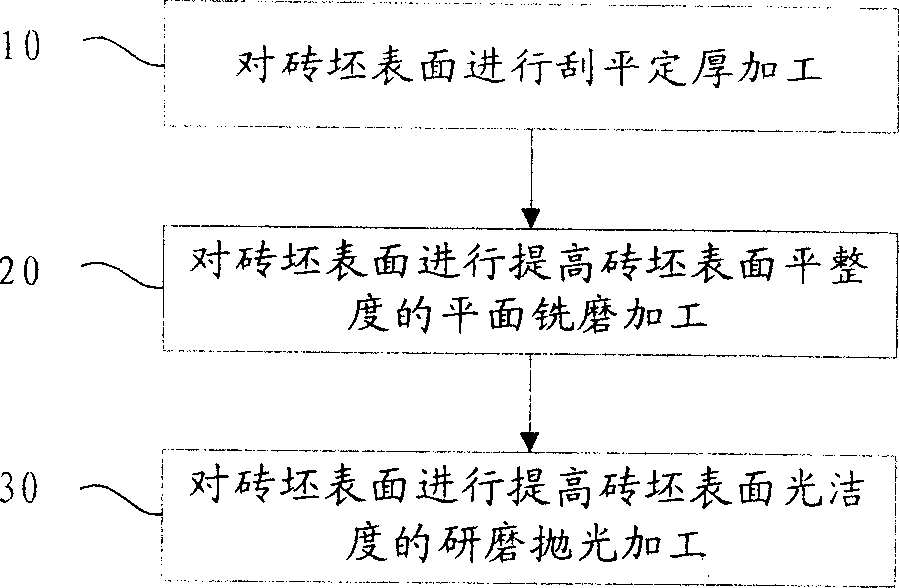

[0040] figure 1 It is a flow chart of the processing method for porcelain polished brick surface of the present invention, including steps:

[0041] Step 10, the surface of the adobe is scraped and thickened;

[0042] Step 20, carry out planar milling processing on the surface of the adobe to improve the flatness of the adobe surface;

[0043] Step 30, performing grinding and polishing on the surface of the adobe to improve the smoothness of the adobe surface.

[0044]The above technical solution of the present invention adds a plane milling process between the scraping and thickness determination process and the grinding and polishing process of the prior art, wherein the plane milling process is the processing method proposed for the first time in the present invention and applied to the surface treatment of adobe. It is used for the flatness treatment of the surface of adobe. The efficiency and precision of the surface leveling treatment are between the scraping in the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com