Container having a mixture of phase-change material and graphite powder

A technology of phase change materials and mixtures, which is applied in containers, thermal insulation containers, drinking vessels, etc., and can solve the problems of low thermal conductivity of phase change materials and inability to make optimal use of them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

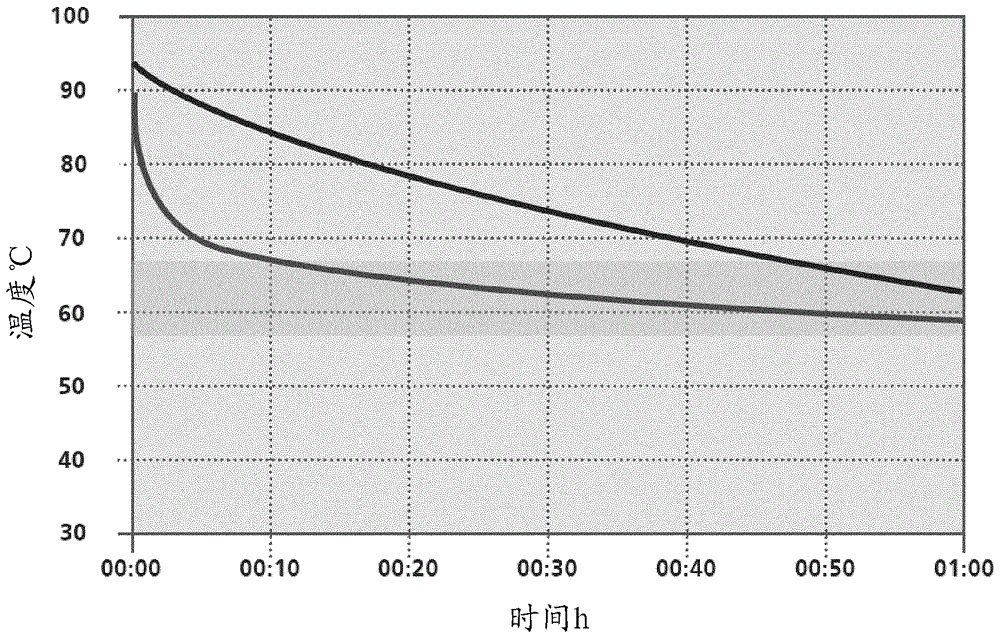

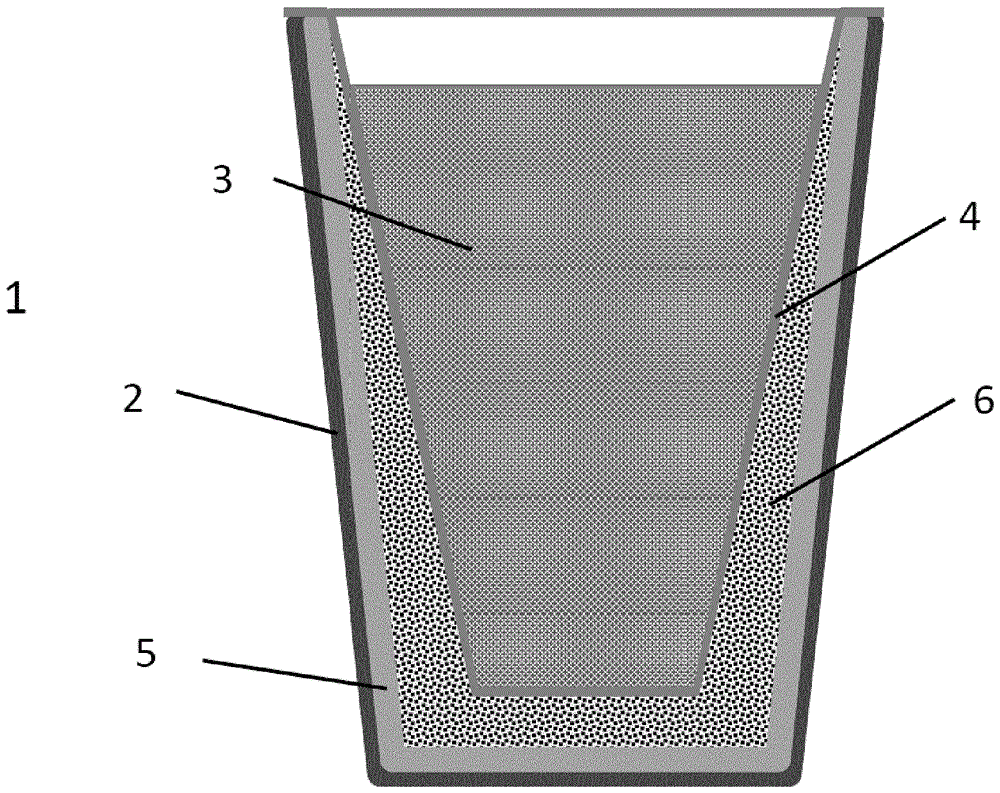

[0036] A beverage container 1 is shown, which is constructed in the form of a "coffee-to-go" cup. The outer container wall 2 made of plastic can be seen here. The inside of the container can be filled with hot drinks in the use volume 3. The container utilization volume 3 is surrounded by an inner container wall 4 . The inner container wall 4 is formed by using a material that conducts heat well, it is made of aluminum or steel. An intermediate space 5 is formed between the inner container wall 4 and the outer container wall 2 . This intermediate space is filled with mixture 6, which contains phase change material and graphite powder. despite following figure 1 For reasons of illustration, only a part of the intermediate space 5 is filled with the mixture 6 , but in principle it makes sense to fill as much as possible of the entire intermediate space 5 with the mixture 6 . Note of course that the mixture 6 has a slightly smaller volume in the solidified state of the phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com