Formula and preparation method for cable with good acid and alkali resistance and high temperature resistance

An acid and alkali resistant, high temperature resistant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of people's life and property threats, inappropriate matching, cable use, etc., to achieve performance improvement and molding Short cycle time, excellent effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

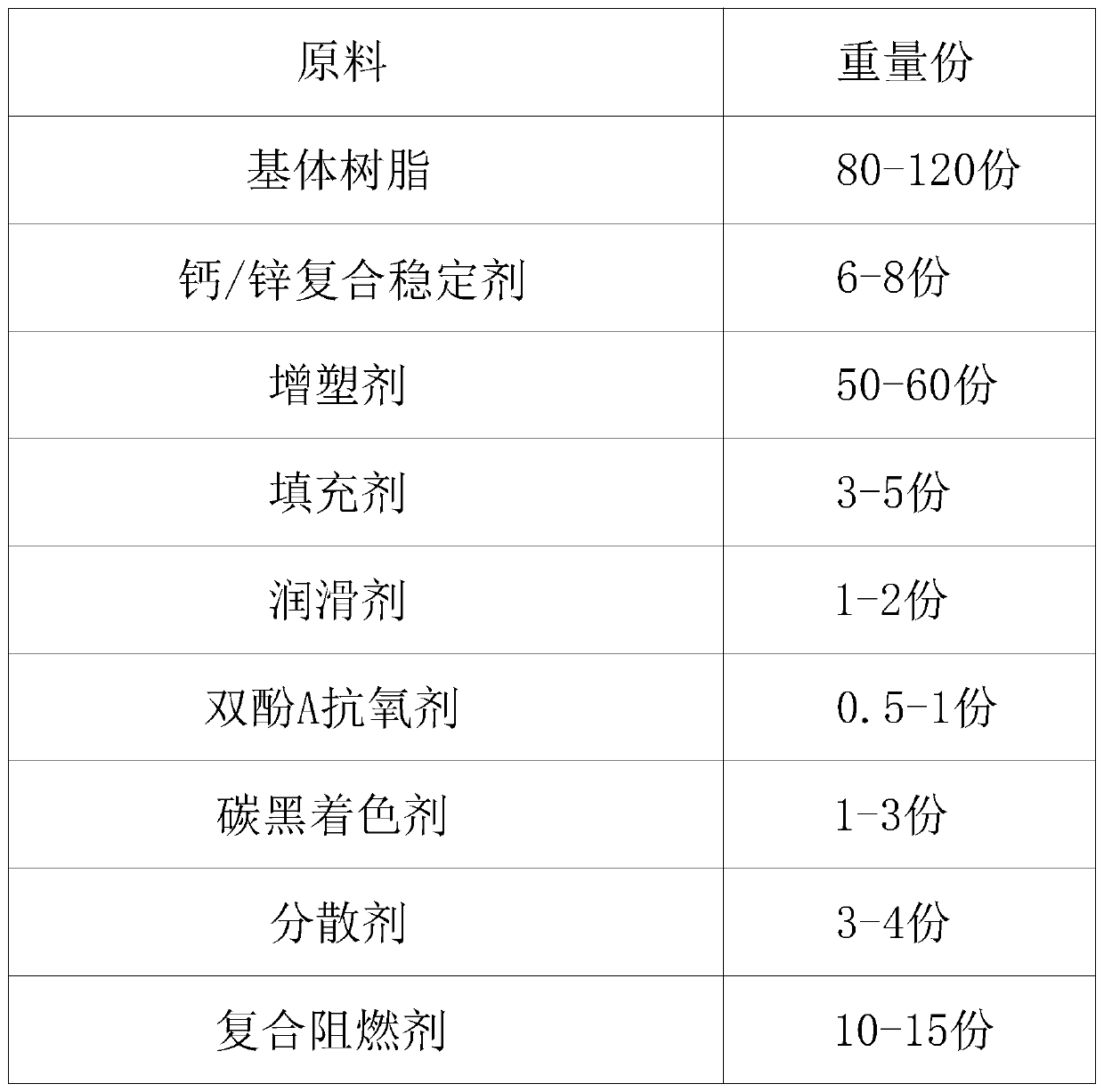

[0025] A cable formula with good acid and alkali resistance and high temperature resistance, the formula includes the following raw materials in parts by weight: 100 parts of matrix resin, 6 parts of calcium / zinc composite stabilizer, 55 parts of plasticizer, 4 parts of filler, lubricant 2 parts of agent, 0.5 parts of bisphenol A antioxidant, 3 parts of carbon black colorant, 3 parts of dispersant, 10 parts of composite flame retardant.

[0026] Further, the matrix resin is set to be a mixture of polytetrafluoroethylene resin, polyether ether ketone resin and polybutylene adipamide resin, and the polytetrafluoroethylene resin, polyether ether ketone resin and polybutylene adipamide resin The mass ratio is set to 4:1:1.

[0027] Further, the plasticizer is set as a mixture of trioctyl trimellitate, diundecyl phthalate and ditridecyl phthalate, and trioctyl trimellitate, didecyl phthalate The mass ratio of monoester and ditridecyl phthalate was set at 1:1:1.

[0028] Further, ...

Embodiment 2

[0037] A cable formula with good acid and alkali resistance and high temperature resistance, the formula includes the following raw materials in parts by weight: 100 parts of matrix resin, 6 parts of calcium / zinc composite stabilizer, 55 parts of plasticizer, 4 parts of filler, lubricant 2 parts of agent, 0.5 parts of bisphenol A antioxidant, 3 parts of carbon black colorant, 3 parts of dispersant, 10 parts of composite flame retardant.

[0038] Further, the matrix resin is set to be a mixture of polytetrafluoroethylene resin, polyether ether ketone resin and polybutylene adipamide resin, and the polytetrafluoroethylene resin, polyether ether ketone resin and polybutylene adipamide resin The mass ratio is set to 3:1:1.

[0039] Further, the plasticizer is set as a mixture of trioctyl trimellitate, diundecyl phthalate and ditridecyl phthalate, and trioctyl trimellitate, didecyl phthalate The mass ratio of monoester and ditridecyl phthalate was set at 1:1:1.

[0040] Further, ...

Embodiment 3

[0049] A cable formula with good acid and alkali resistance and high temperature resistance, the formula includes the following raw materials in parts by weight: 100 parts of matrix resin, 6 parts of calcium / zinc composite stabilizer, 55 parts of plasticizer, 4 parts of filler, lubricant 2 parts of agent, 0.5 parts of bisphenol A antioxidant, 3 parts of carbon black colorant, 3 parts of dispersant, and 15 parts of composite flame retardant.

[0050] Further, the matrix resin is set to be a mixture of polytetrafluoroethylene resin, polyether ether ketone resin and polybutylene adipamide resin, and the polytetrafluoroethylene resin, polyether ether ketone resin and polybutylene adipamide resin The mass ratio is set to 2:1:1.

[0051] Further, the plasticizer is set as a mixture of trioctyl trimellitate, diundecyl phthalate and ditridecyl phthalate, and trioctyl trimellitate, didecyl phthalate The mass ratio of monoester and ditridecyl phthalate was set at 1:1:1.

[0052] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com