Galvanized steel sheet water heater antirust water tank and corrosion prevention method thereof

A galvanized steel sheet, water heater technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of high manufacturing cost, technical difficulty of enamel heating water tank, easy rust, etc., achieve low manufacturing cost, overcome easy rust, Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

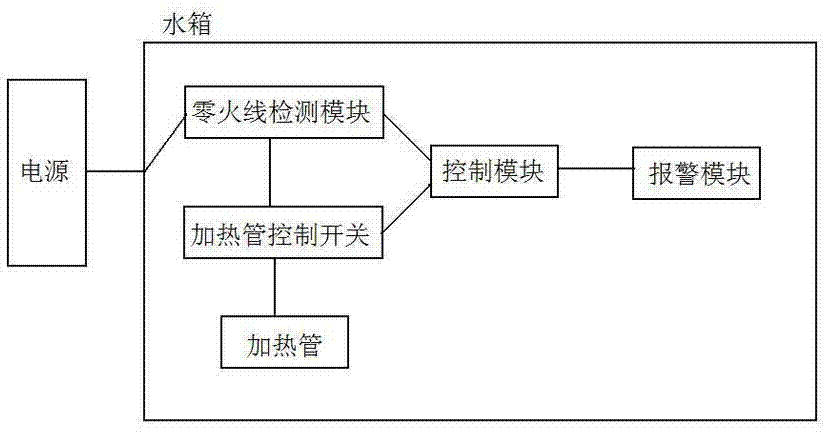

[0018] like figure 1 , figure 2 The antirust water tank of a galvanized steel water heater includes: a heating pipe and a control module, a heating pipe control switch, a zero live wire detection module and an alarm module.

[0019] The connection relationship of the above components is as follows:

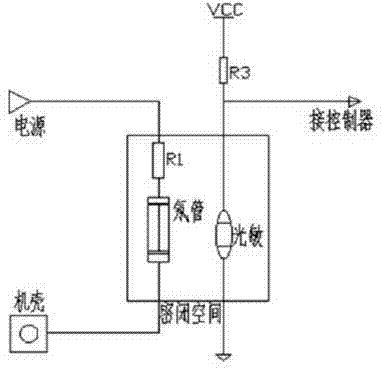

[0020] The control module is connected with the heating tube control switch, the zero live line detection module and the alarm module; the heating tube control switch is located between the heating tube control switch and the heating tube; the external power input line is connected with the zero live line detection module. Wherein, the zero live line detection module includes: a neon tube, a photoresistor, a load resistor R1 and a load resistor R3; the neon tube is opposite to the photoresistor and is located in a closed space, and one end of the neon tube is connected to an external power supply after the load resistor R1 is connected in series. The other end is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com