Manually operated tool

A technology for processing equipment and fuel tanks, applied in metal processing equipment, sawing equipment, mechanical equipment, etc., can solve troublesome problems, achieve the effects of reducing the number of structural parts, simplifying manufacturing, and compacting the shell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

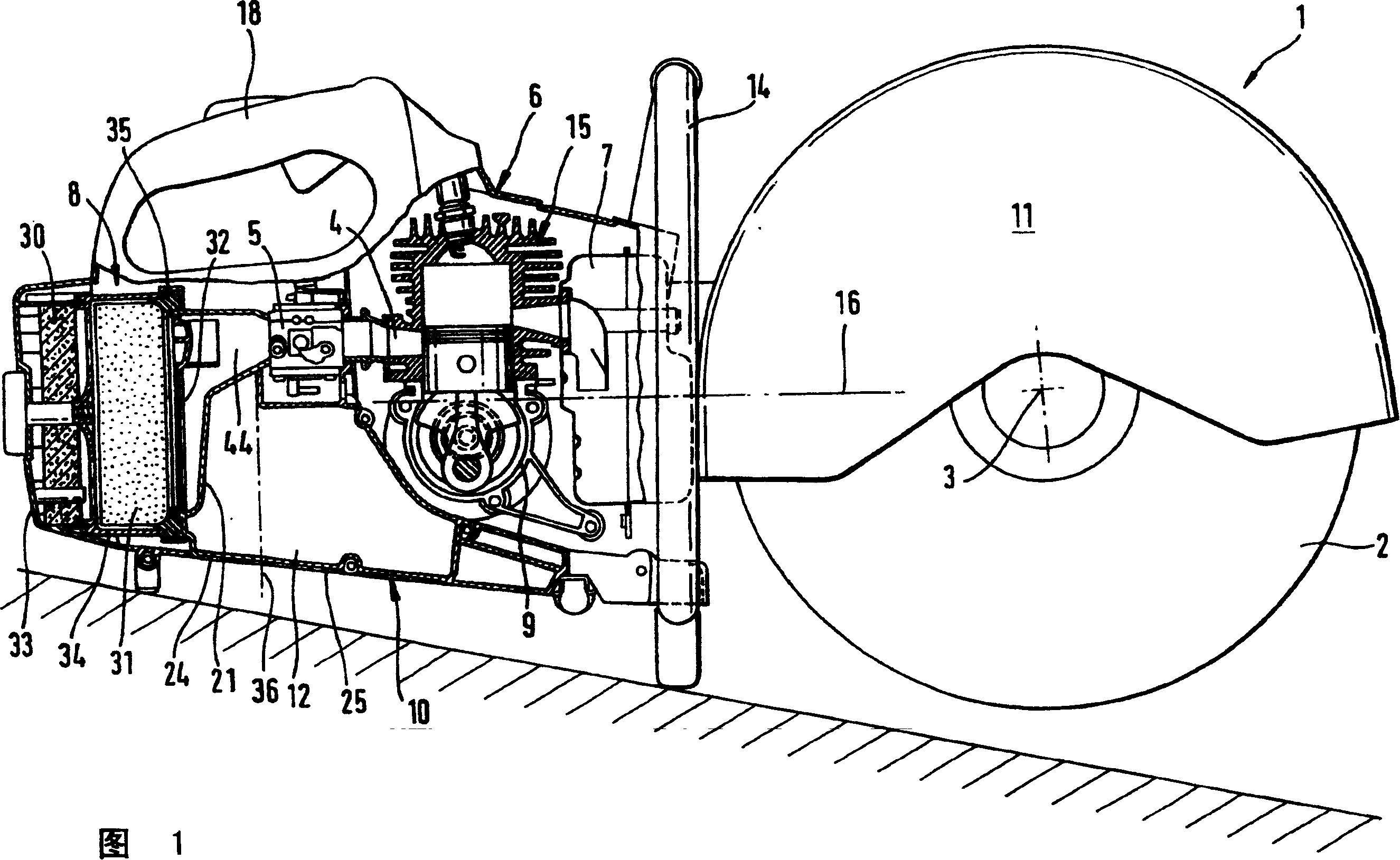

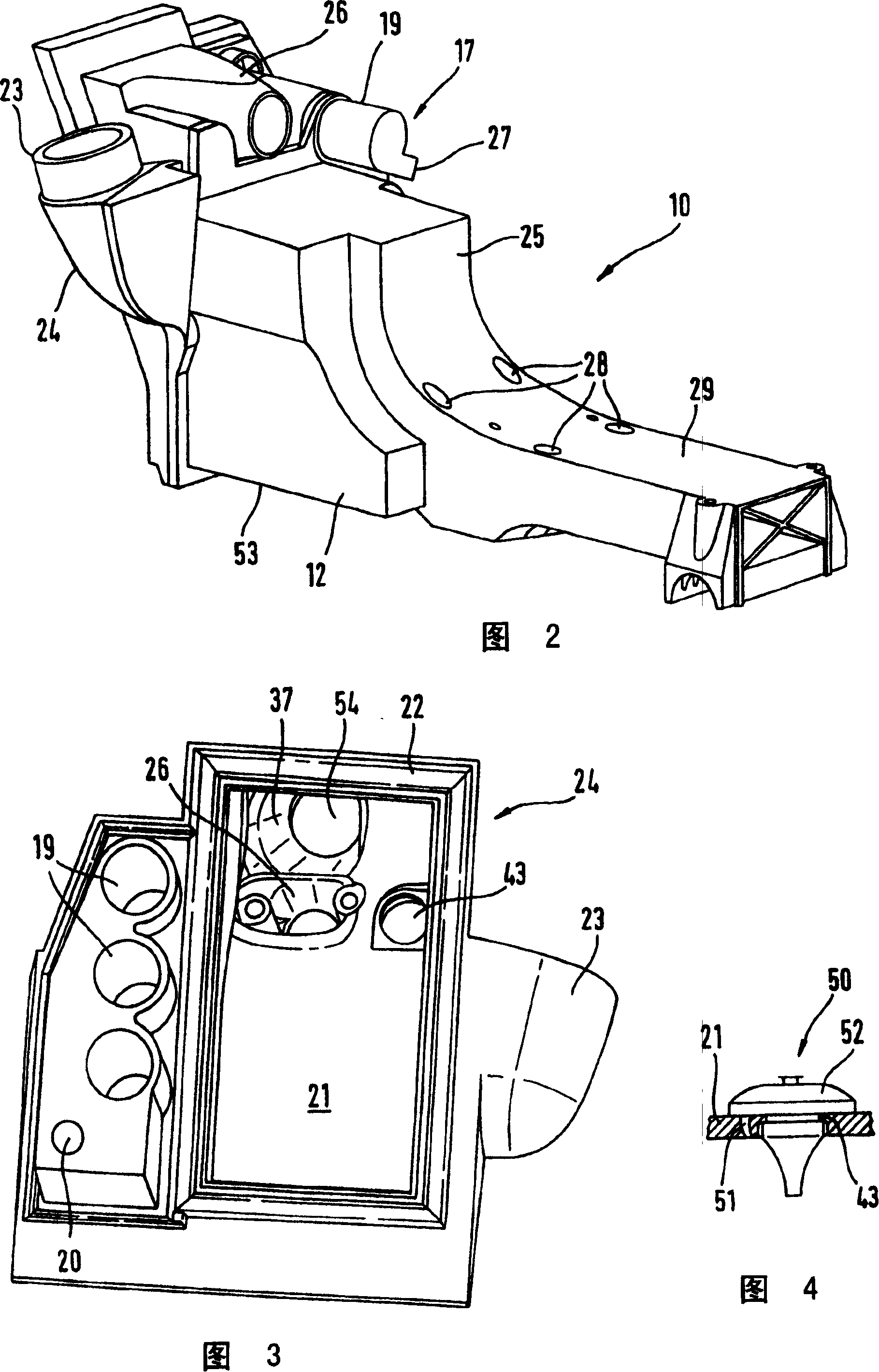

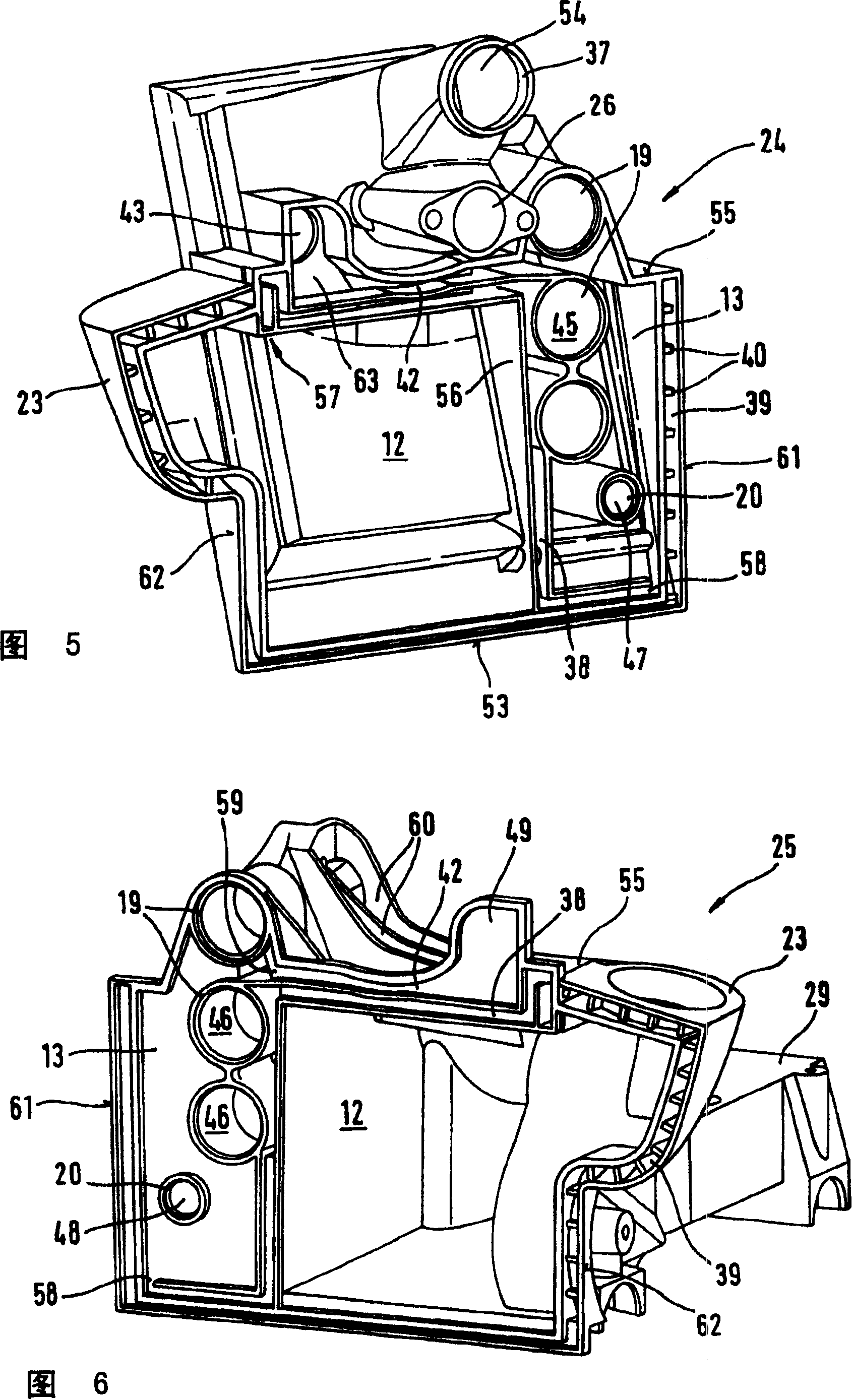

[0016] FIG. 1 shows a cutting machine 1 with a cutting blade 2 which is driven in rotation about an axis 3 . The cutting blade 2 is partially surrounded by a protective cover. The cutting machine 1 has a housing 6 in which a two-stroke motor 15 is arranged, which drives the cutting blade 3 via a belt (not shown). An exhaust muffler 7 is set on the outlet of the two-stroke engine. The two-stroke engine 15 supplies a fuel / air mixture via an intake channel 4 , which is processed in a carburetor 5 . The evaporator 5 is connected to the clean air side 44 of the air cleaning unit. The air cleaning unit comprises an air filter unit 8 having a pre-filter 30 arranged inside an end cap 33 , a main filter 31 inside an air filter housing 34 and a fine filter 32 . The air filter housing is closed by an air filter base plate 21 .

[0017] The cutting machine 1 has a fuel tank housing 10 which is arranged on an air filter base 21 . The fuel tank housing 10 is formed from two half shells...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com