Antilocking mechanism of star feeder

A star-shaped feeding and anti-jamming technology, applied to conveyors, rotary conveyors, transportation and packaging, etc., can solve problems such as material blocking and accumulation, and achieve the effect of economical processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and examples.

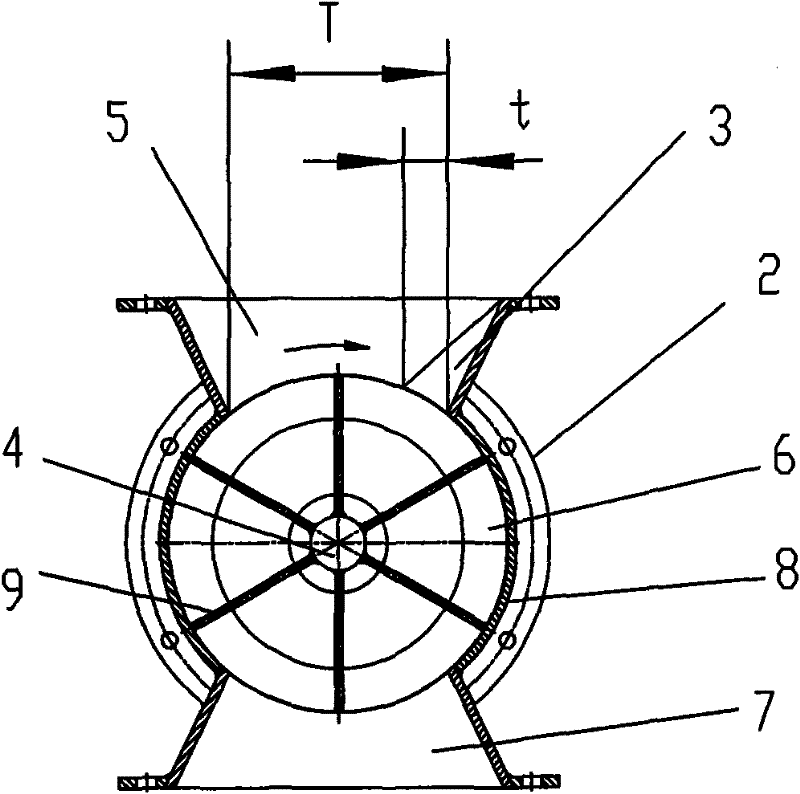

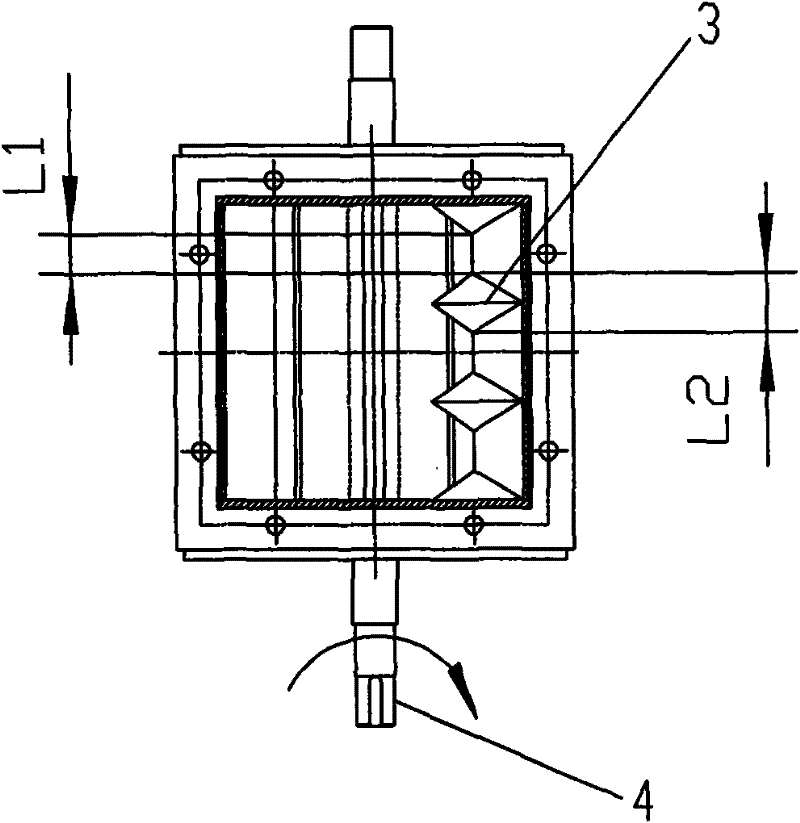

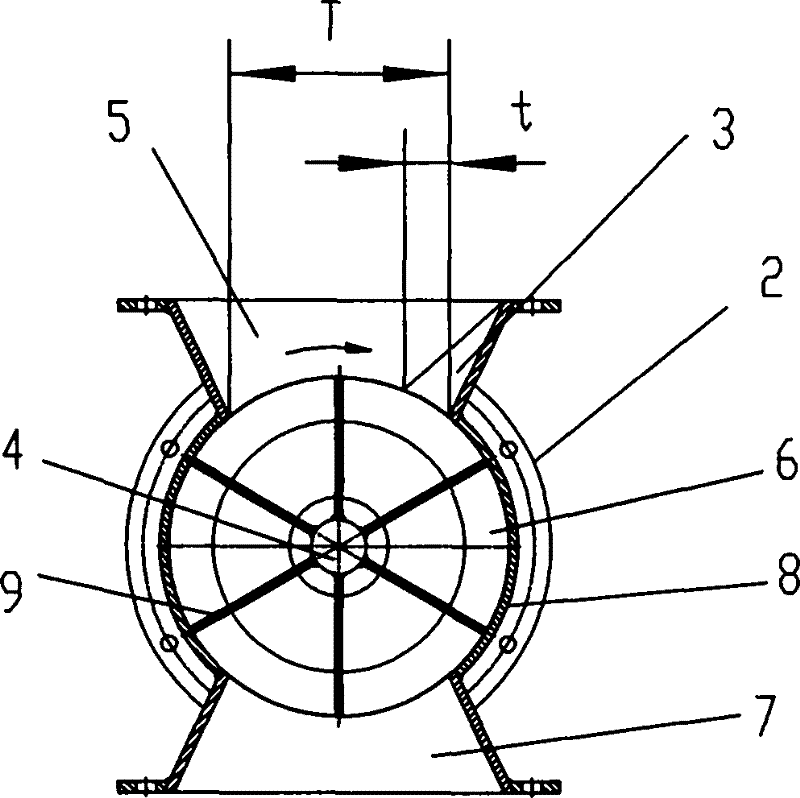

[0011] As shown in the figure: the anti-seize mechanism includes a star wheel rotor, an outer casing 2, a V-shaped boss 3, a transmission shaft 4, a material inlet 5, an inner cavity 6, a material outlet 7, and a casing 8, etc.

[0012] The upper end of the shell 8 is a funnel-shaped feed inlet 5, the lower end of the shell 8 is a funnel-shaped discharge port 7, and the shell 8 is an inner cavity 6, and a star wheel rotor is arranged in the inner cavity 6, and the star wheel rotor is connected to the inner cavity 6. The transmission shaft 4 installed on the casing 8 is connected; several bosses are arranged on the inner wall of the side of the feed inlet 5 in the same rotation direction as the star wheel rotor. figure 1 Shown is the state that the star wheel rotor rotates clockwise (as shown by the arrow in the figure). At this time, the materials enter the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com