Efficient forced lubrication system with circulating lubrication function for coal mining machine

A technology of circulating lubrication and lubrication system, applied in the direction of gear lubrication/cooling, mechanical equipment, belt/chain/gear, etc., can solve the problems of lack of oil, low lubrication efficiency, inability to directly lubricate low-speed end bearings, etc., to achieve low production costs , High space utilization, the effect of simplifying the layout of oil passages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

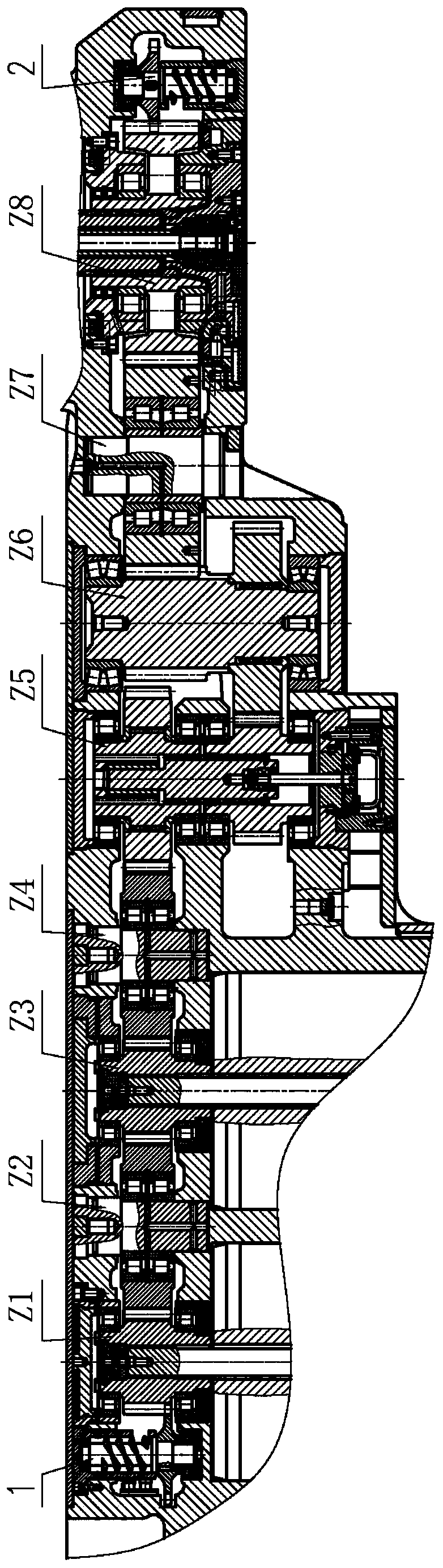

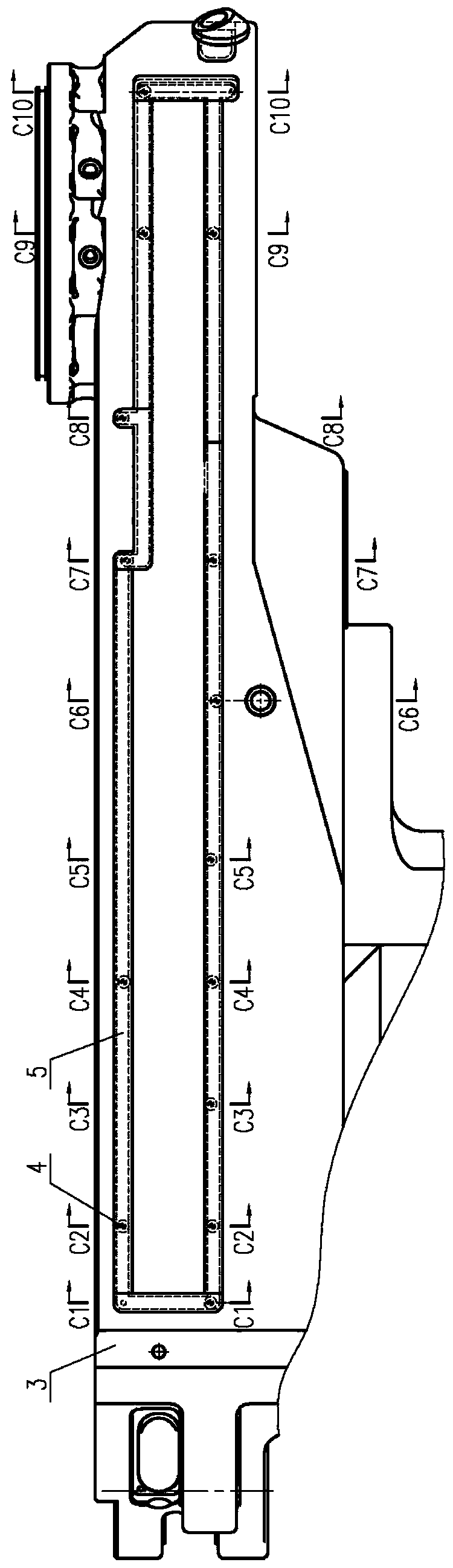

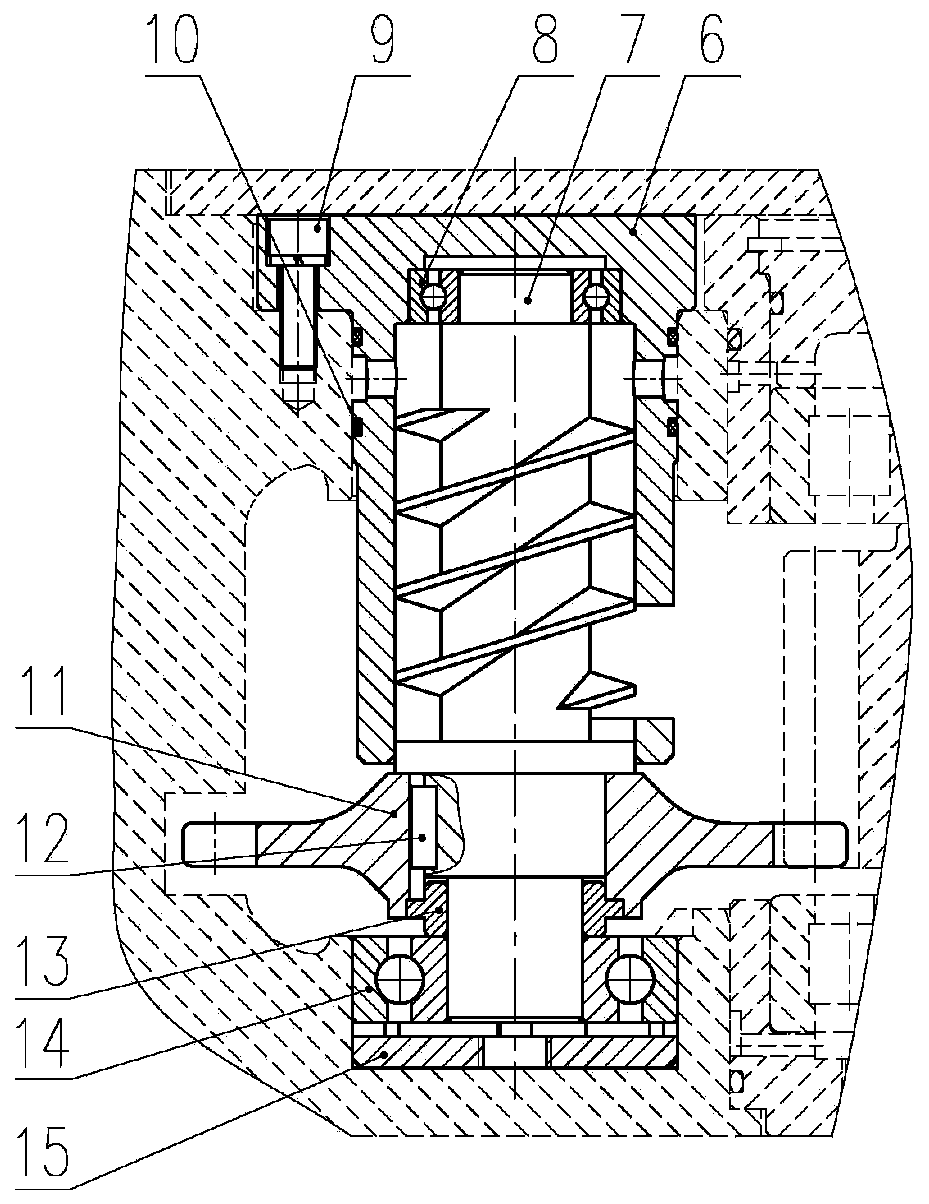

[0036] The invention discloses a high-efficiency forced lubrication system (lubrication system for short) of a coal shearer with a circulating lubrication function, such as Figure 1-15As shown, it includes high-speed lubricating pump 1, low-speed lubricating pump 2 and lubricating oil passages. The high-speed lubricating pump and low-speed lubricating pump are arranged in the transmission box of the rocker arm and form a row with each shaft of the rocker arm transmission system. Arranged in parallel and located on the outside of the first and last two shaft groups respectively, the first and last two shaft groups are respectively the shaft group with the highest speed and the shaft group with the lowest speed. The lubricating oil passage is arranged in the transmission box housing 3 of the rocker arm. The lubricating oil passage includes a main oil passage 16 and multiple sets of branch oil passages, and the main oil passage passes through the lubrication points of the branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com