Centrifuges, in particular, for a lubricant oil in an internal combustion engine

A technology for centrifugal separators and internal combustion engines, which is applied in the directions of lubrication of engines, installation/connection of centrifuges and lubricant purification devices, etc., can solve the problems of heavy rotors, expensiveness, and unfavorable separation of dirt, and achieves reduction of processing costs and simplification. Effects of spare parts inventory and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

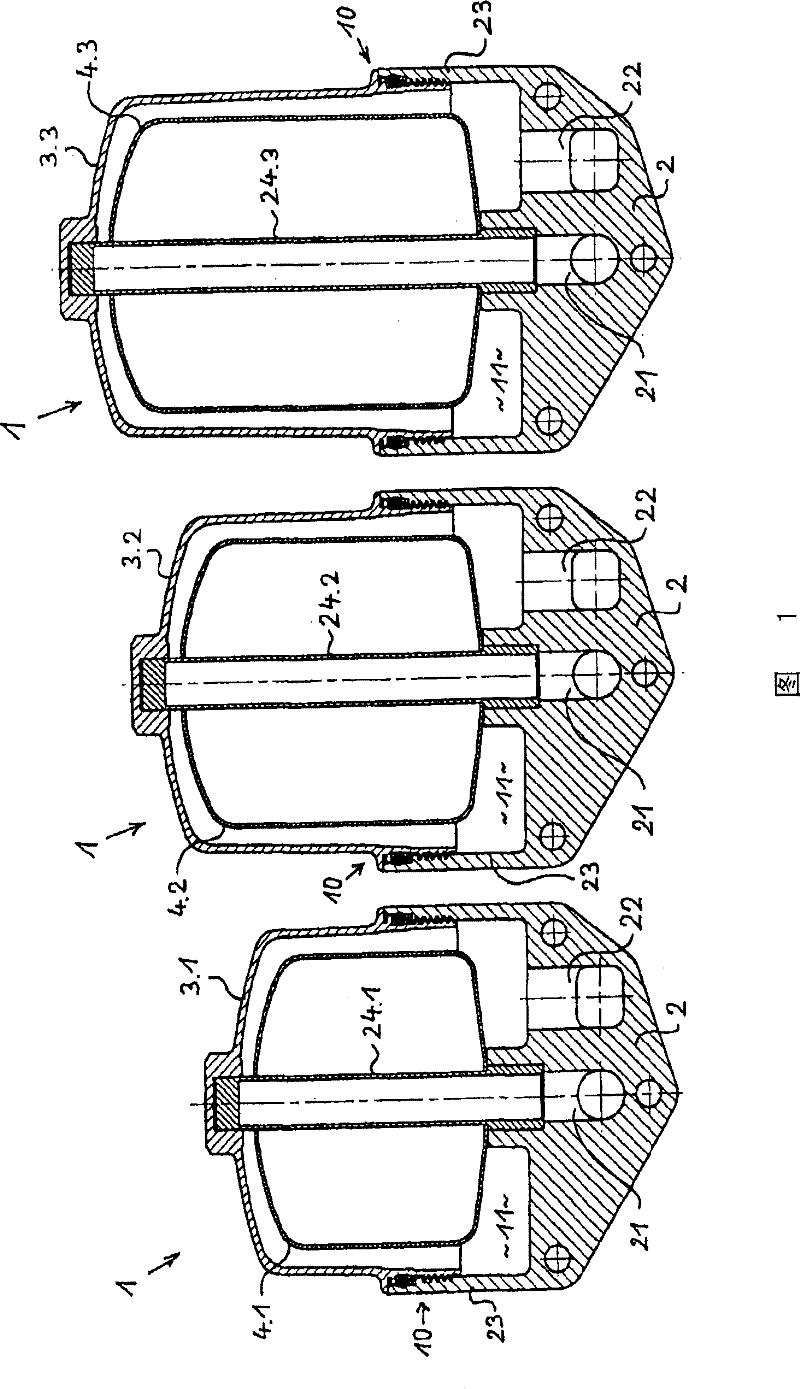

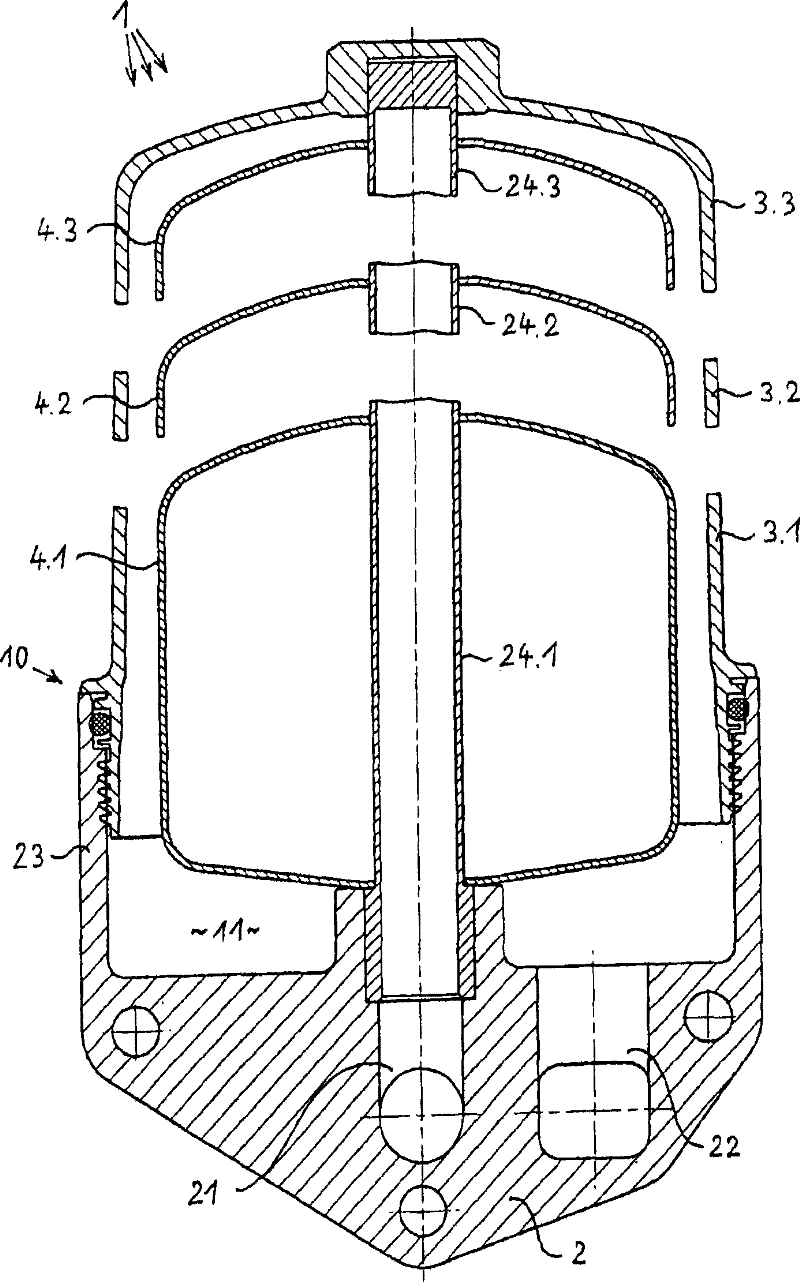

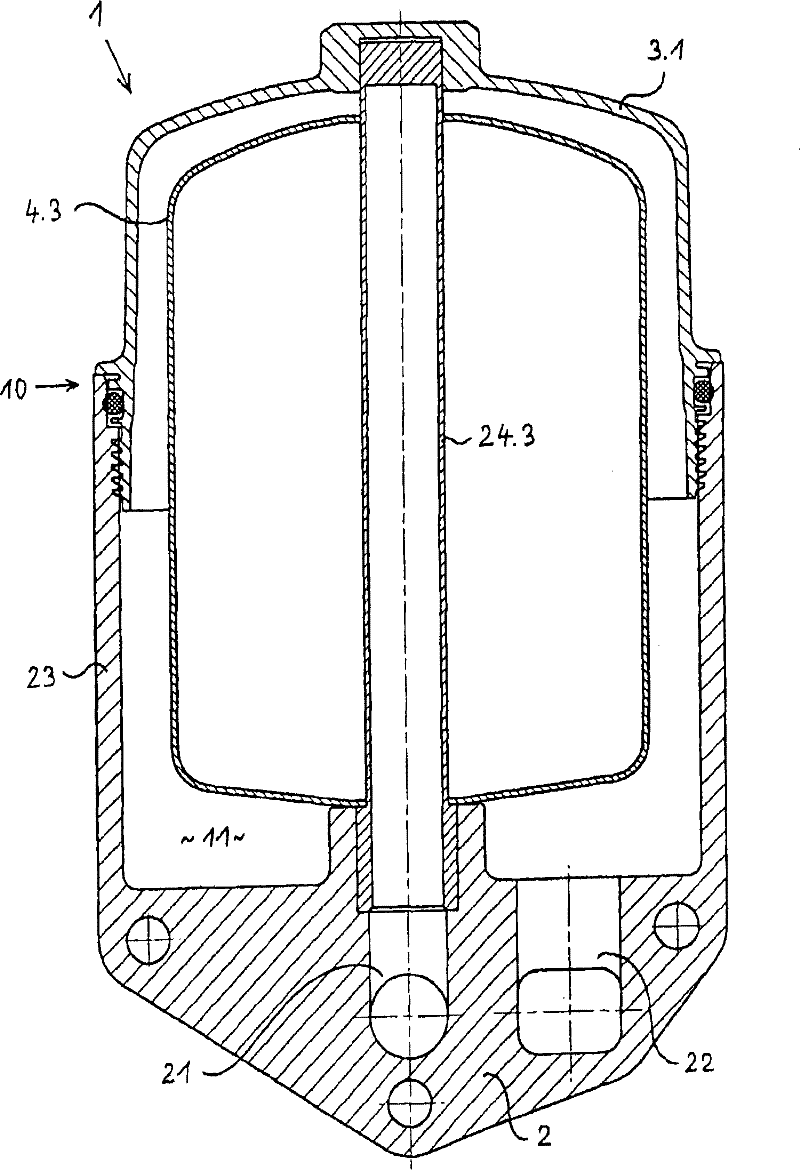

[0031] figure 1 Three different centrifugal separators 1 arranged next to each other are shown, which are characterized in that they have mutually congruent bases 2 which each form a lower housing part. Each base 2 comprises an inlet channel 21 for the liquid to be cleaned in the centrifugal separator 1 , for example the associated internal combustion engine lubricating oil, and an outlet channel 22 for the cleaned liquid from the centrifugal separator 1 . Furthermore, each base 2 includes a peripheral wall 23 which extends upwards. for in figure 1 Each of the three centrifugal separators 1 shown in FIG. 1 has a cover 3.1, 3.2, 3.3 connected to the peripheral wall 23, here detachably bolted with a sealing ring in between. The caps 3.1 to 3.3 each have a congruent connecting end for connection to the peripheral wall 23 downwards, but upwards have a mutually different height, as figure 1 as shown.

[0032] A shaft 24.1 or 24.2 or 24.3 is respectively arranged in each inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com