Machining tool for steel-inlaid guide rail shaped like Chinese character Shan

A guide rail processing and guide rail technology, which is applied to metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of difficult to ensure processing accuracy and difficult processing of mountain-shaped steel-inlaid guide rails, so as to achieve reduced processing costs and high processing efficiency. , to achieve the effect of batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

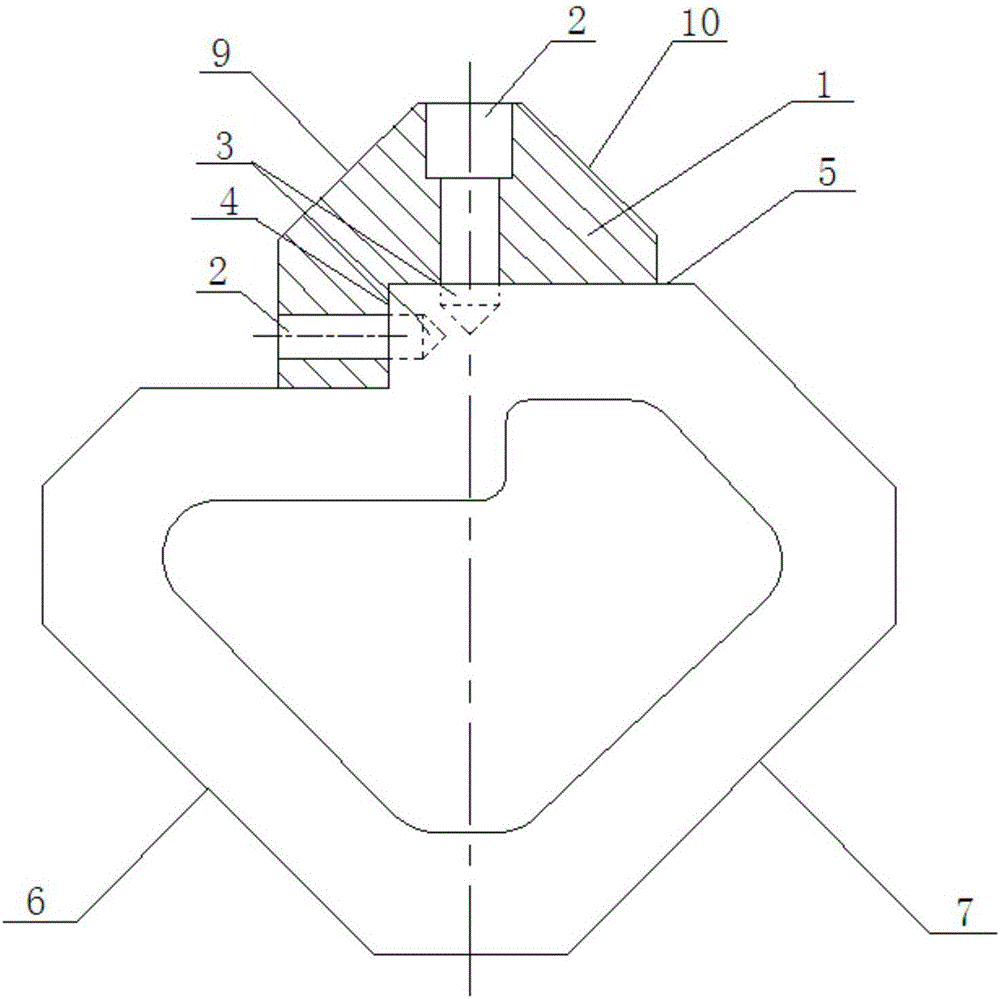

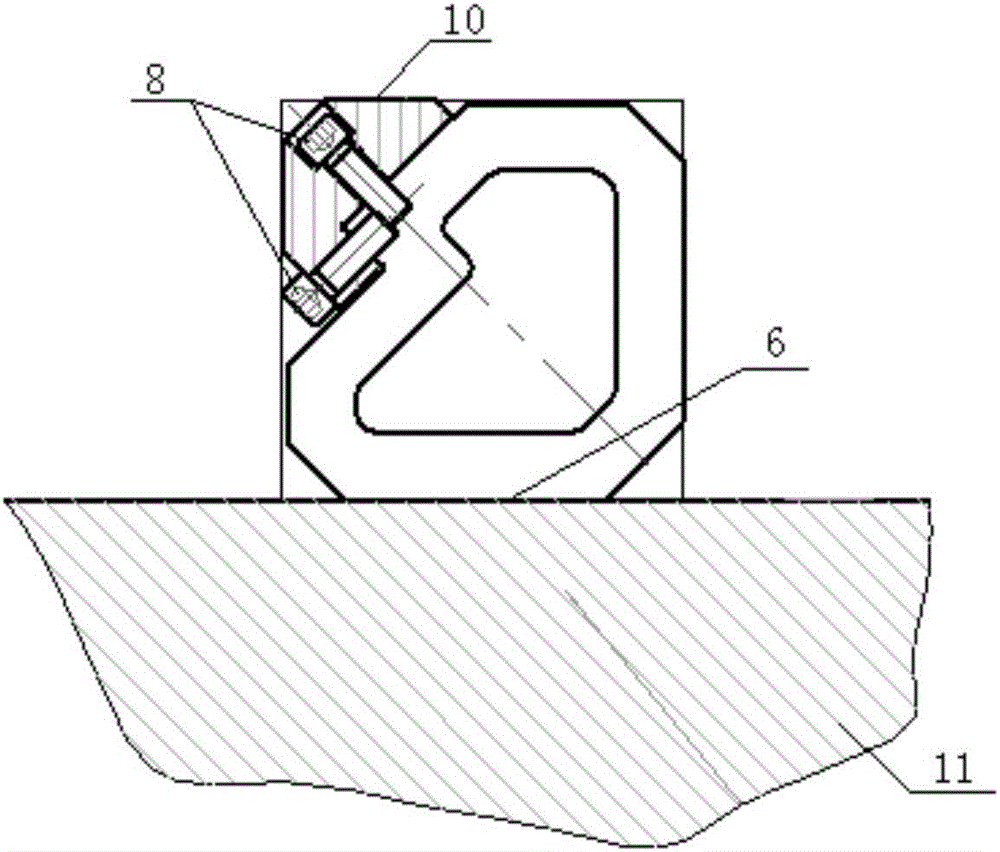

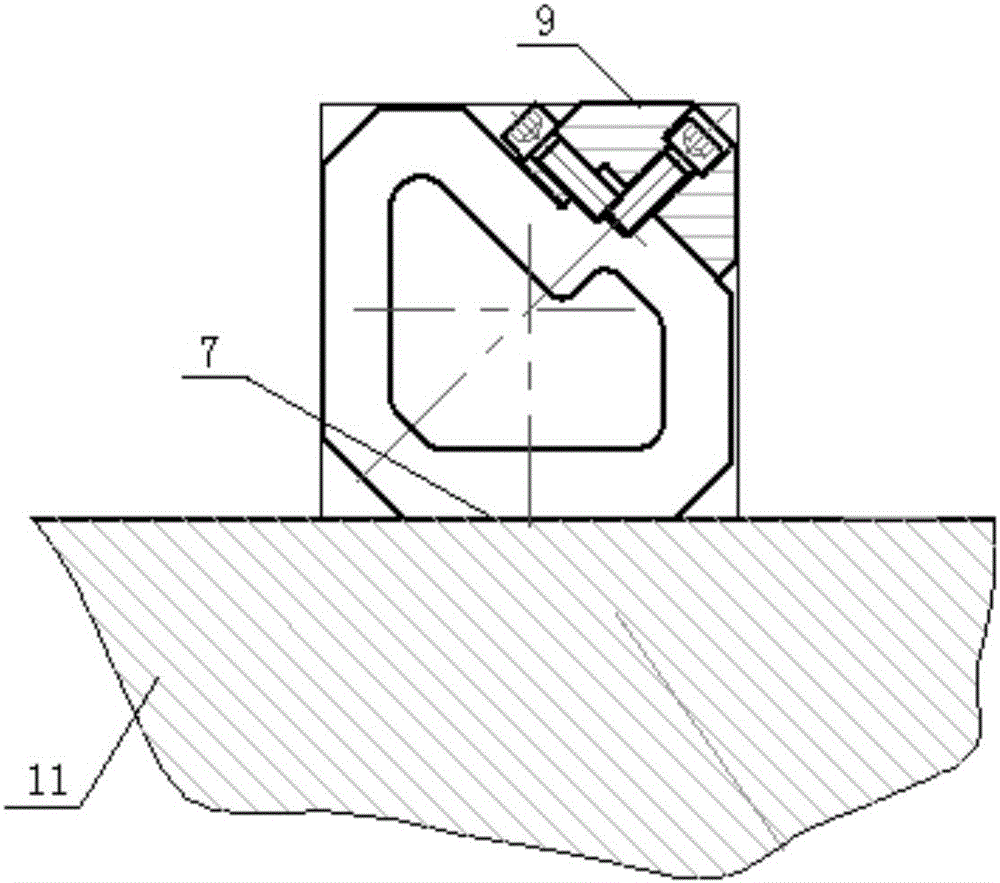

[0011] Attached below Figure 1-3 An embodiment of the present invention is described.

[0012] A mountain-shaped steel-inlaid guide rail processing tool is used to fix the mountain-shaped guide rail 1 to be ground. The cross-sectional shape of the tool is a polygonal structure; the polygonal structure includes a first mounting surface 6, a second mounting surface 7, a The reference plane 4 and the second reference plane 5, and the first installation surface 6 and the second installation surface 7 are perpendicular to each other; the first reference plane 4 and the second reference plane 5 are perpendicular to each other to form Adapted stepped structure, and the first reference plane 4, the second reference plane 5 form an angle of 45 degrees with the first installation surface 6, the second installation surface 7 respectively; the first reference plane 4, the second reference plane 5 has internally threaded holes 3 perpendicular to each other, and the mountain-shaped guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com