Small inner bore lathe grooving tool

A technology of inner hole and turning groove, which is applied in the field of turning tools, which can solve the problems of turning out and small inner hole size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

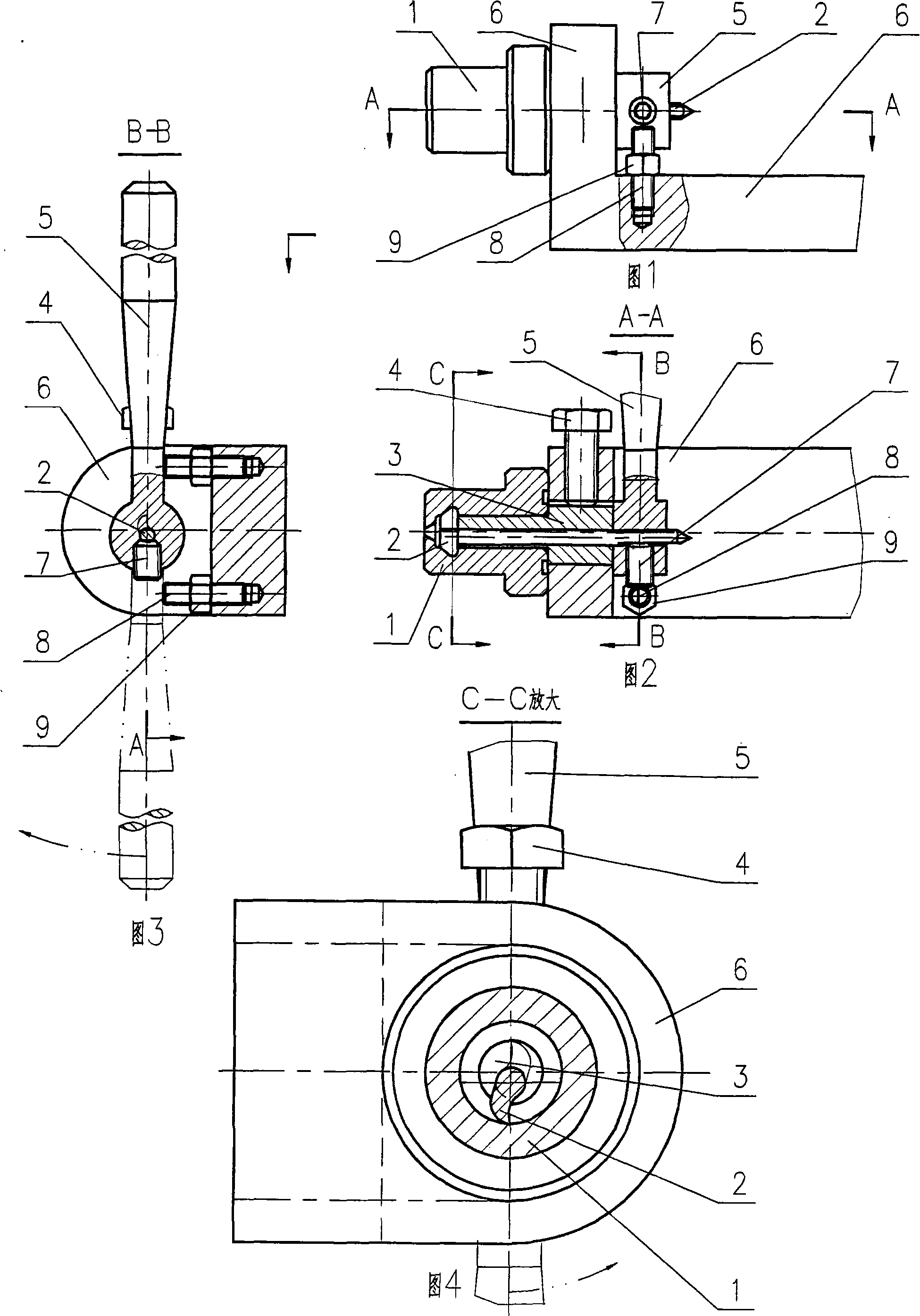

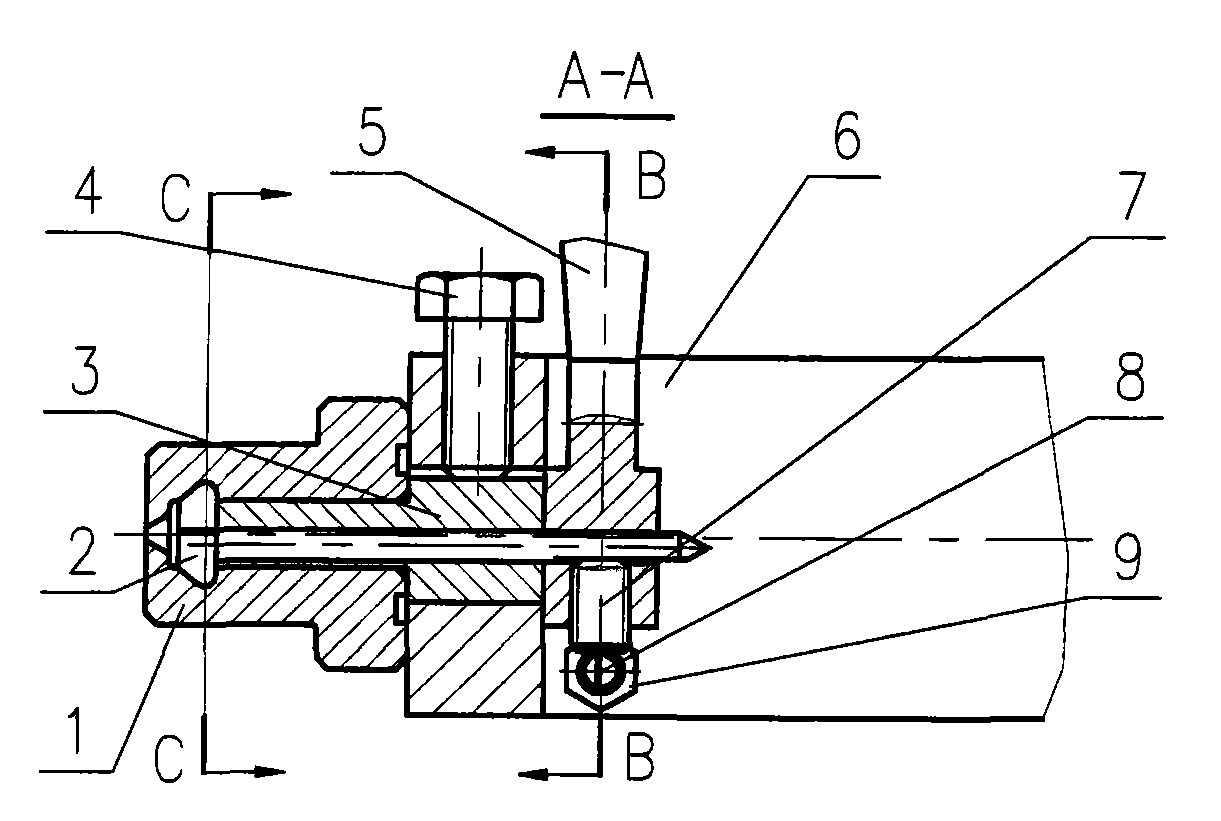

[0014] Accompanying drawing is the small inner hole grooving cutter designed according to the oil storage tank in the needle valve inner hole of processing 195 diesel engine fuel injectors. The inner hole of the needle valve is φ6 mm, and the maximum outer circle of the oil storage tank is φ9.3 mm. Processing is very difficult. See accompanying drawing 1, accompanying drawing 2, accompanying drawing 3 and accompanying drawing 4 for the specific design scheme of the small inner hole grooving cutter.

[0015] In Fig. 2, the small plane at the front end of the bolt (4) is pressed against the plane of the large outer circle of the eccentric sleeve (3) to fix the eccentric sleeve (3) in the hole in front of the cutter body (6) so that the eccentric sleeve (3) The axis line of the small outer circle and the axis line of the eccentric hole are all in the plane parallel to the installation bottom surface of the cutter body (6). The turning tool (2) is contained in the eccentric hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com