Diamond rope saw static force cutting method

A diamond wire saw and cutting method technology, applied in metal processing equipment, grinding machines, construction and other directions, can solve the problems of cutting depth only to 30cm, the degree of refinement is not high, the size of the disc is limited, etc., to achieve high cutting efficiency, The effect of good working environment and low cutting noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] With reference to the following embodiments, the present invention can be explained in more detail; however, it should be noted that the present invention is not limited to the following embodiments.

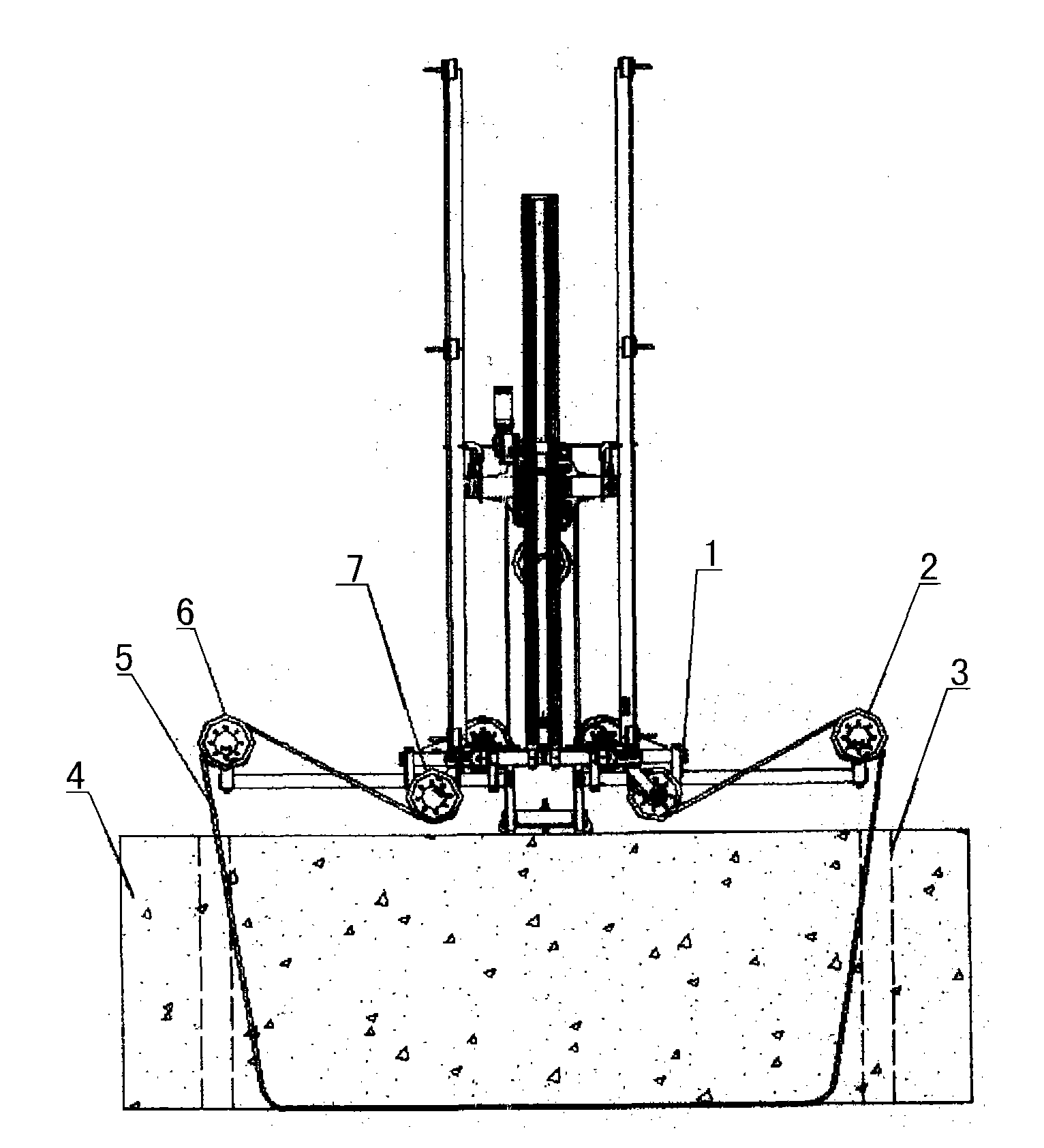

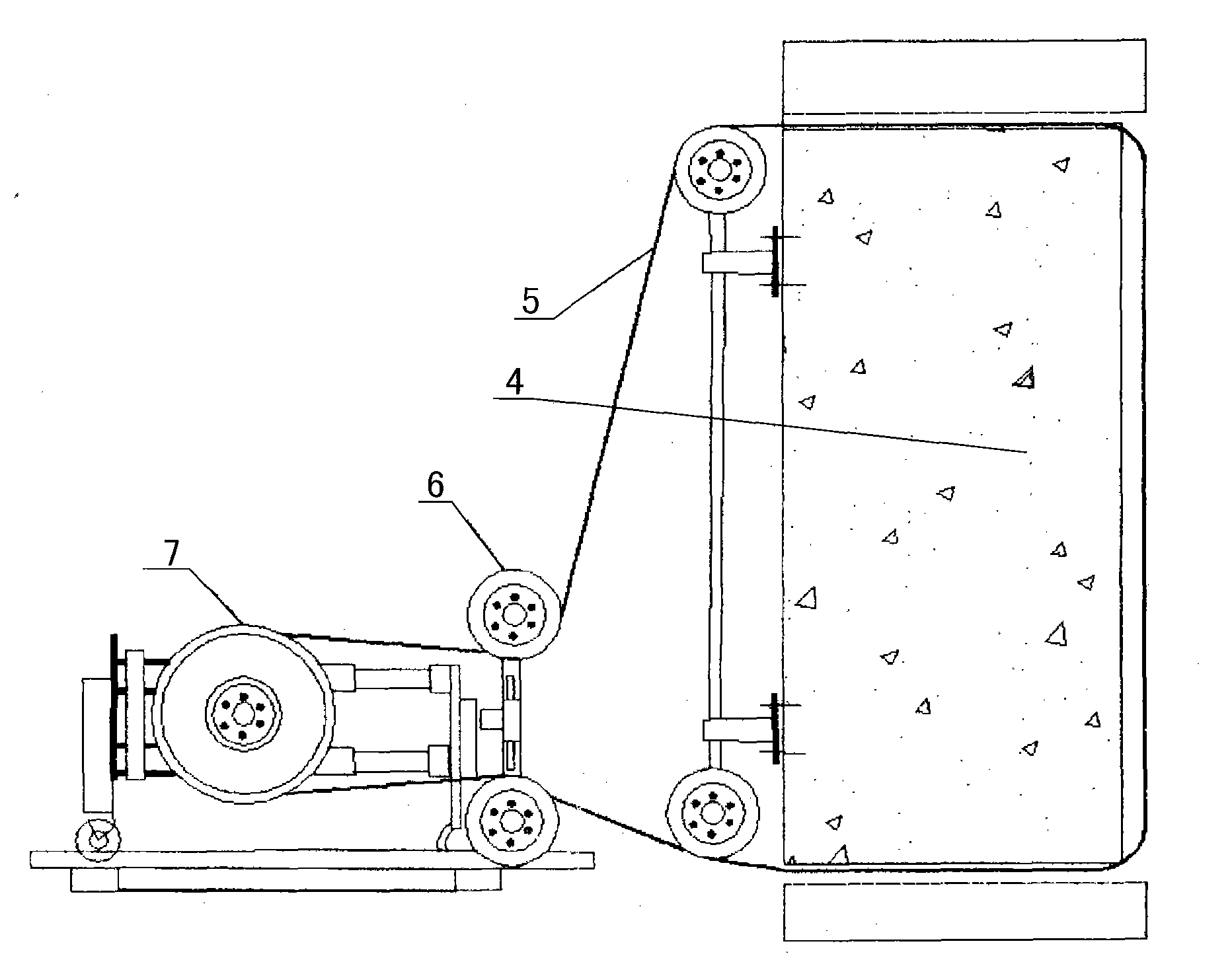

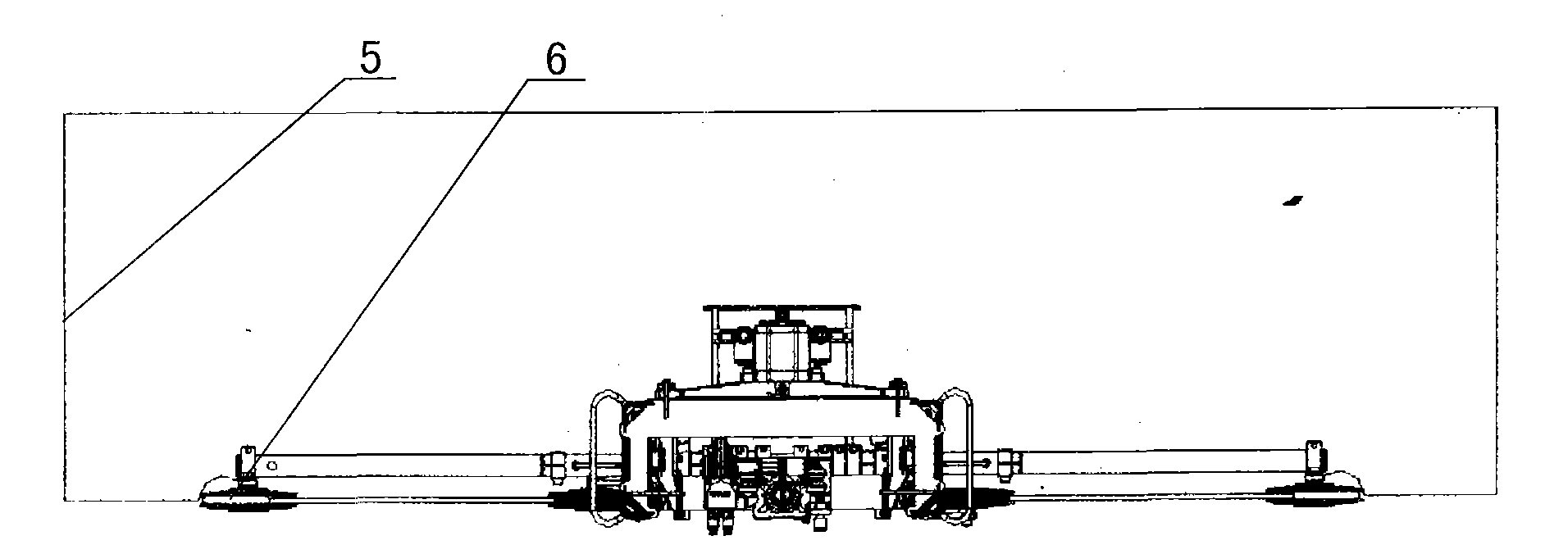

[0036] The static cutting method of the diamond wire saw of the present invention in conjunction with the drawings is particularly suitable for buildings with steel-concrete structures such as bridges, chimneys, railway stations, and buildings with frame structures.

[0037] Attached Figure 1~5 The static cutting method of the diamond wire saw adopts a hydraulic diamond wire saw. The diamond wire saw 5 cuts by the diamond wire saw 5 moving around the cutting surface of the cutting body 4 under the driving of a hydraulic motor to grind the cutting body 4 at high speed. Realize the cutting of the cutting body 4; wherein the abrasive material of the diamond wire saw 5 is diamond particles, and the diamond wire saw 5 is especially suitable for cutting stone, reinforced concrete o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com