Patents

Literature

38results about How to "Effect of flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

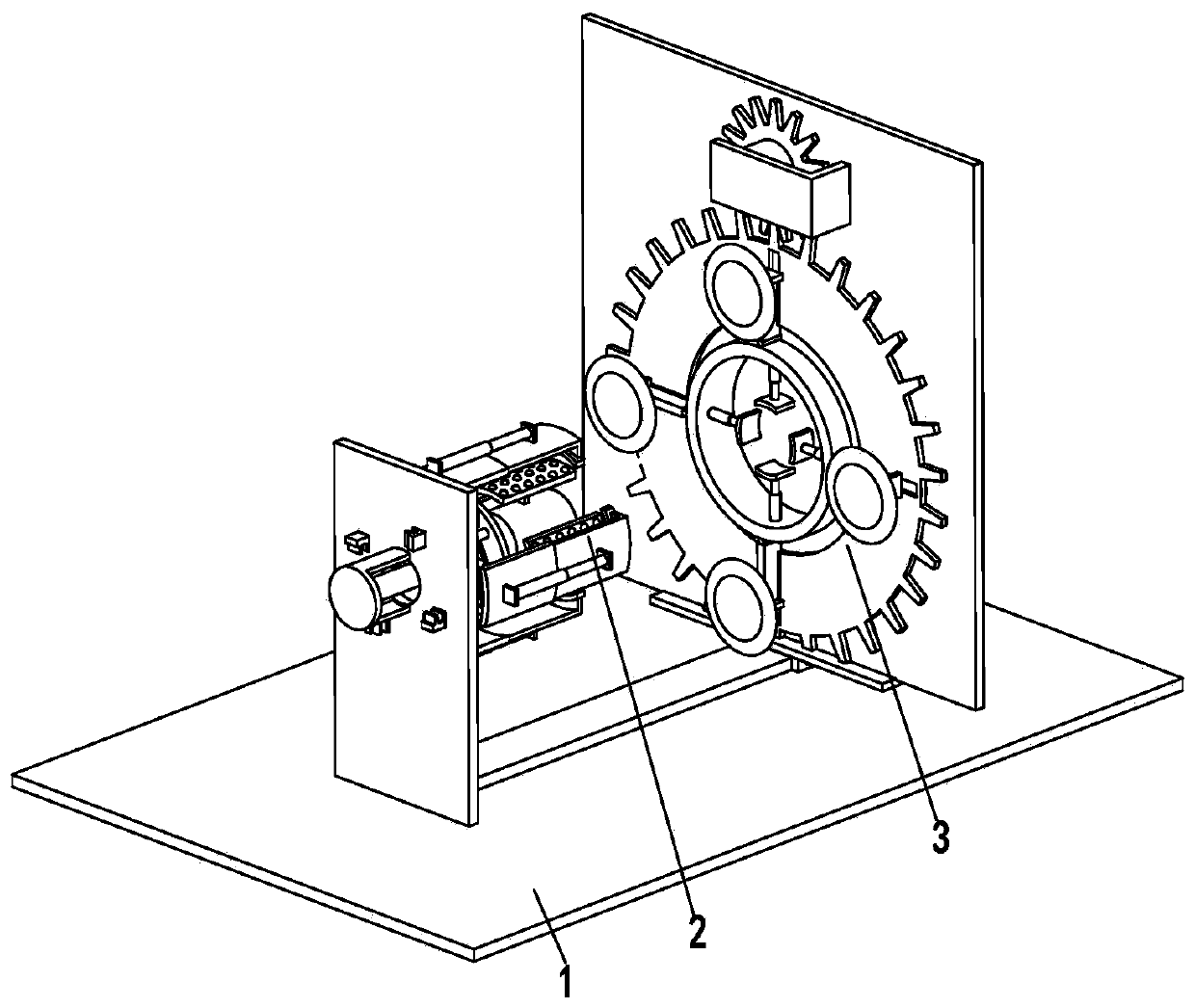

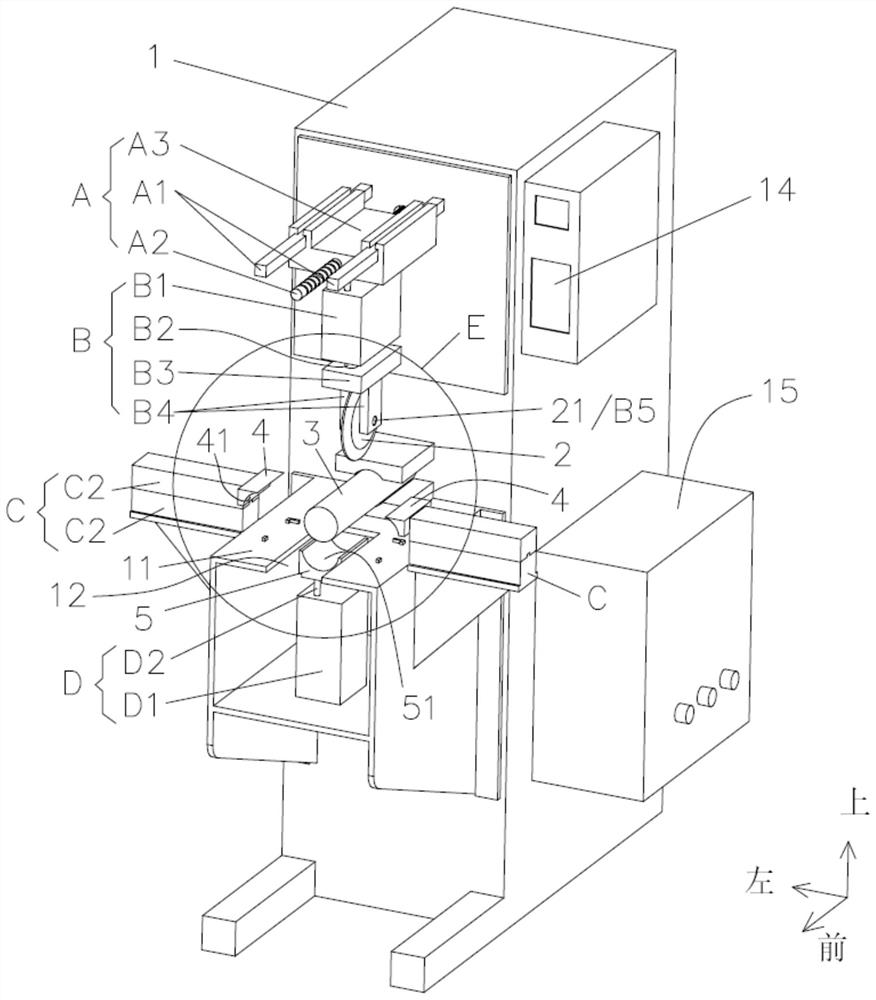

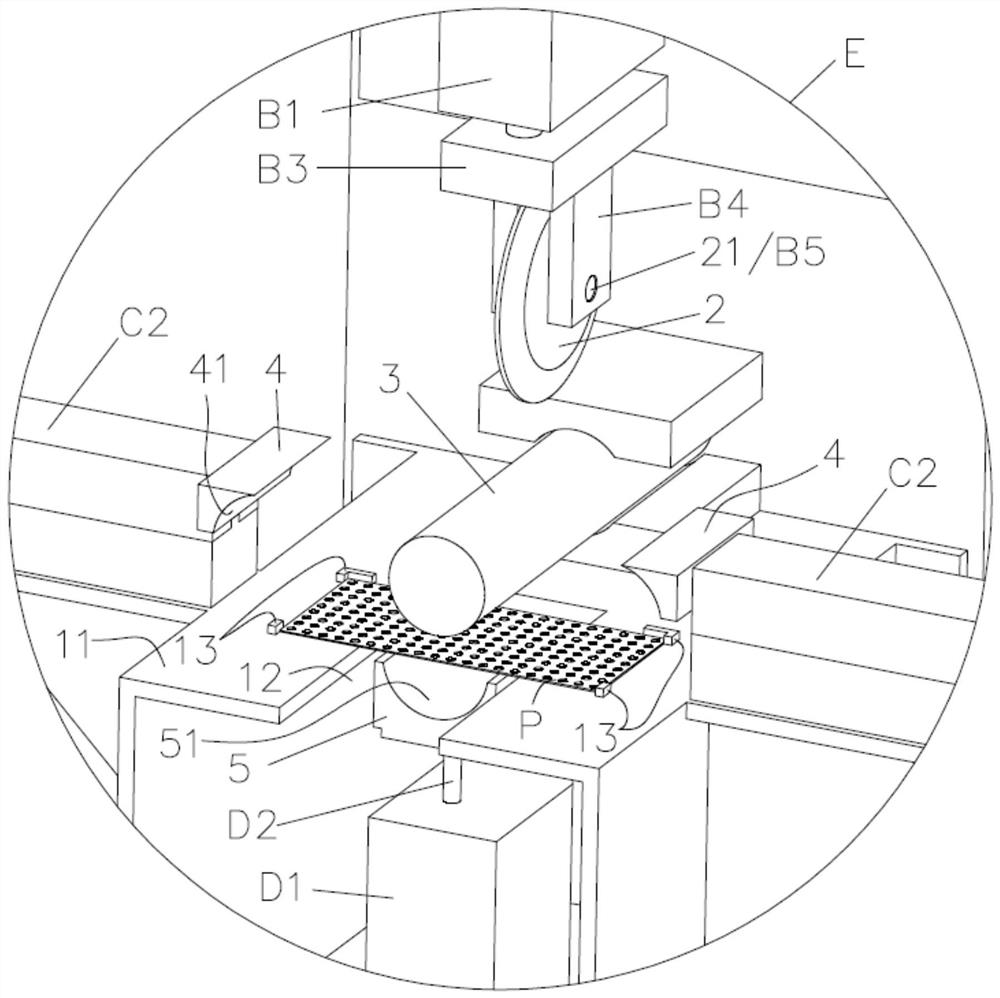

Automatic rubber hose cutting equipment and automatic rubber hose cutting technology

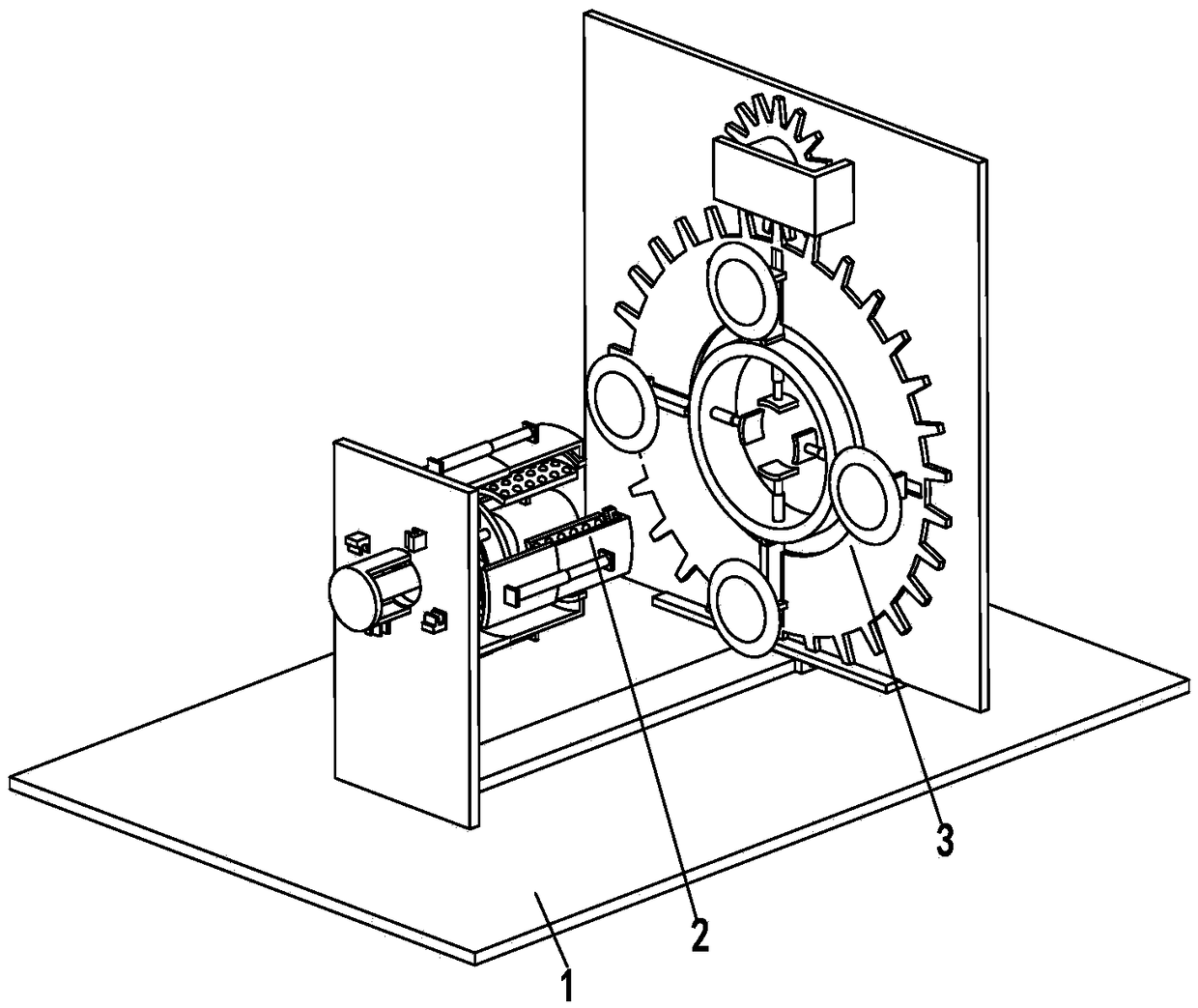

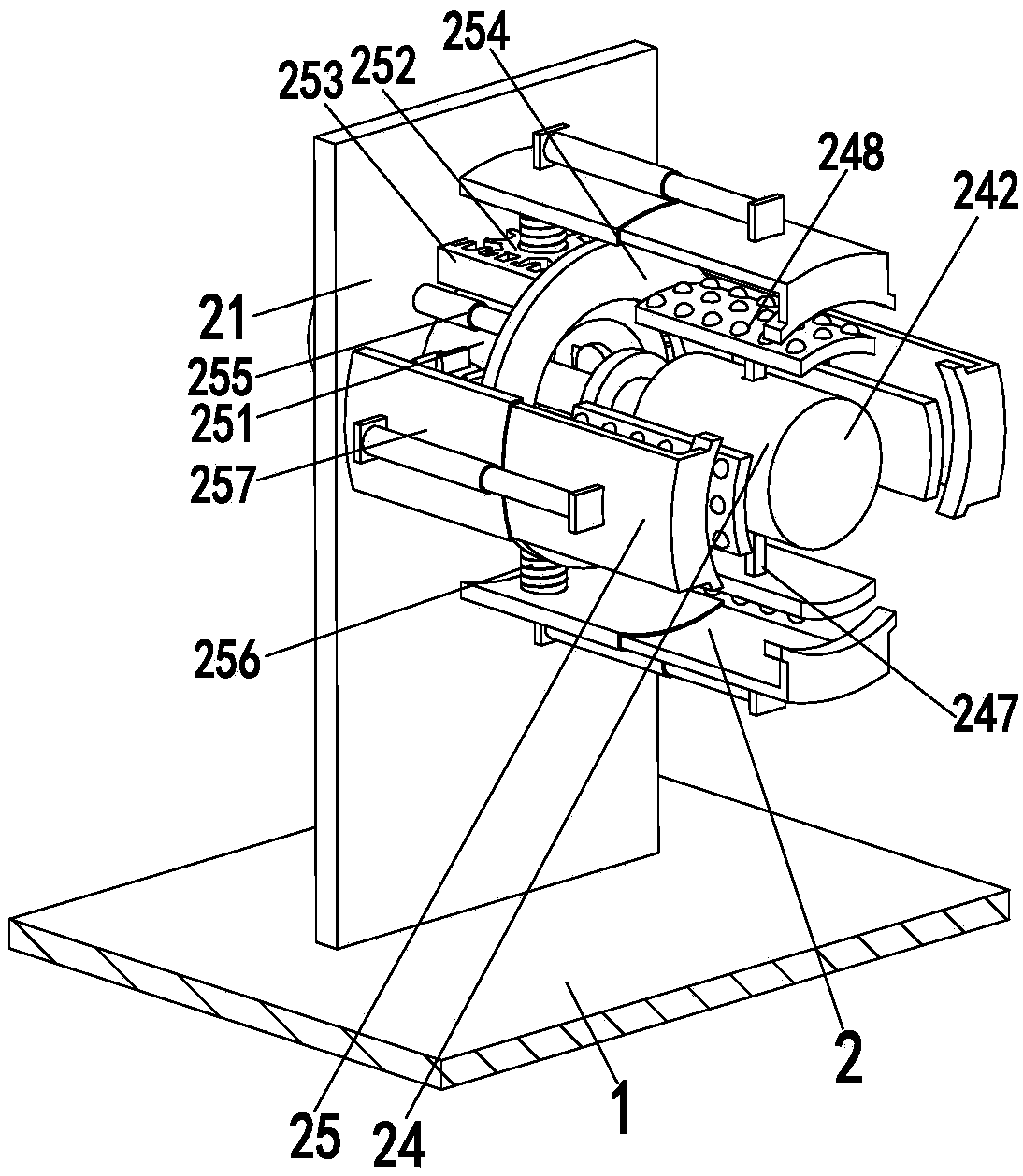

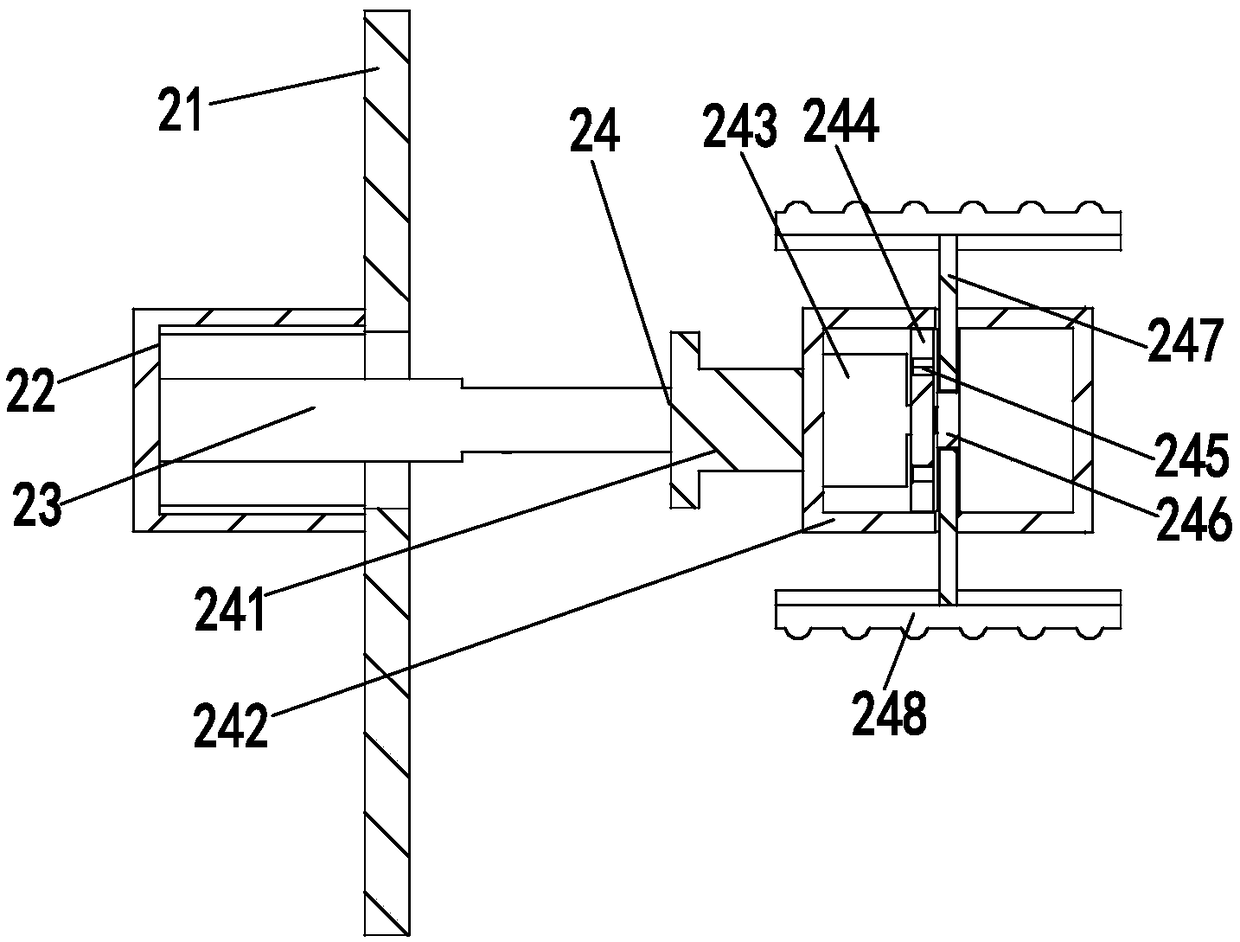

ActiveCN109227674ARealize automatic cuttingNot easy to scratchMetal working apparatusGear wheelFixed frame

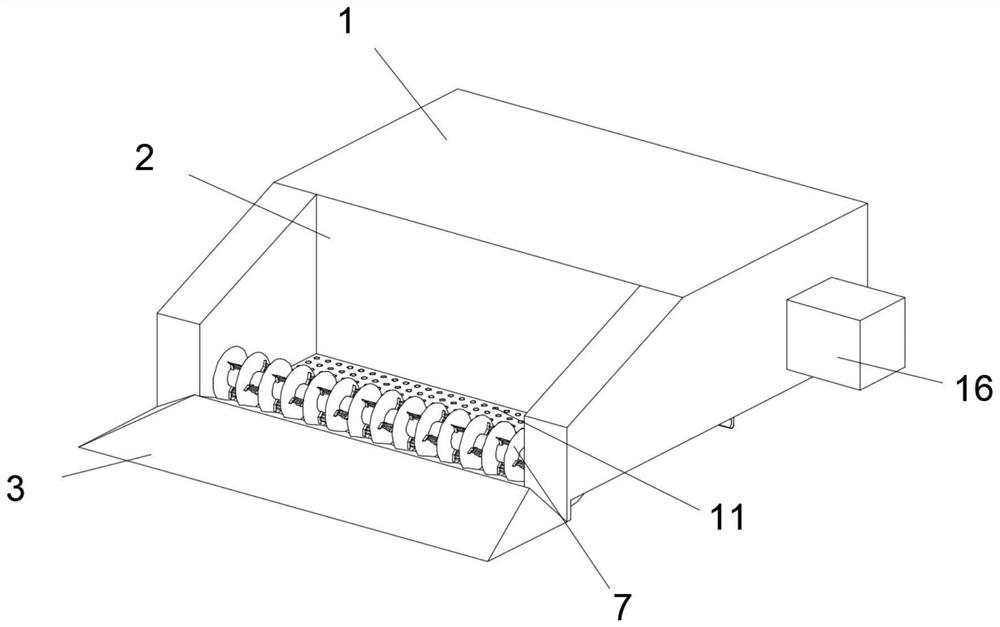

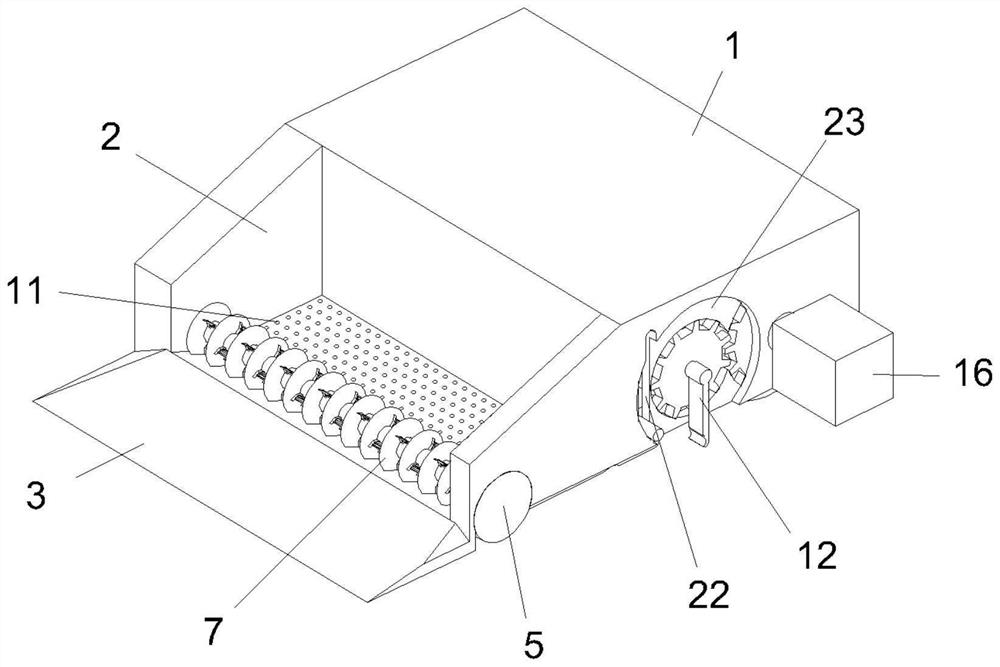

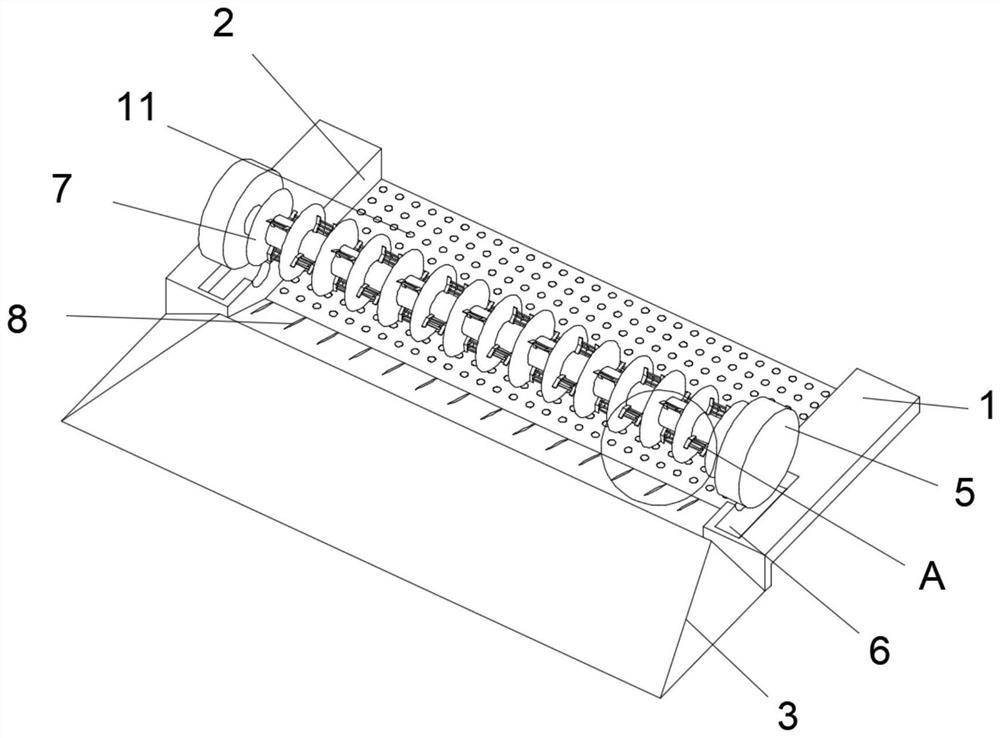

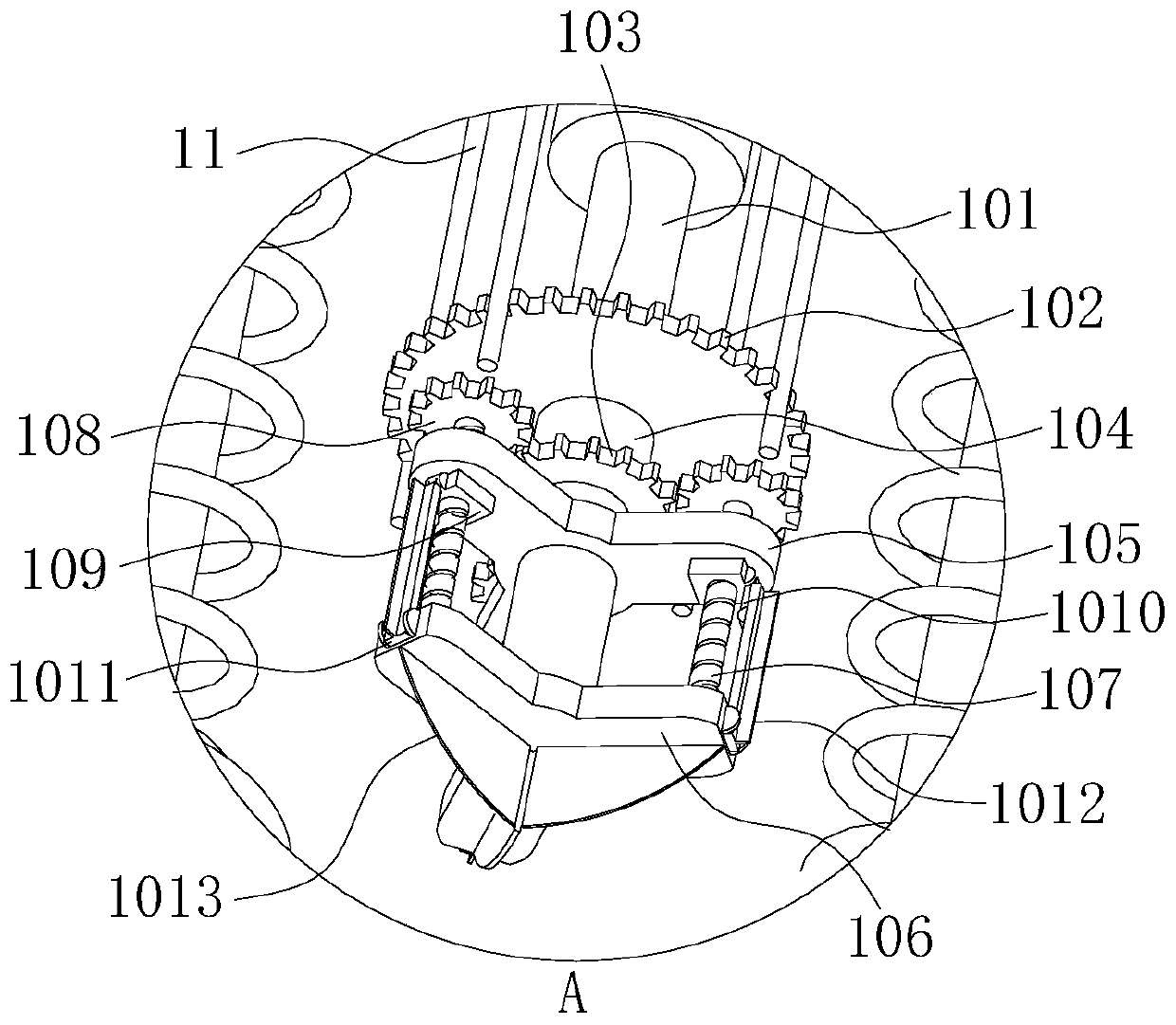

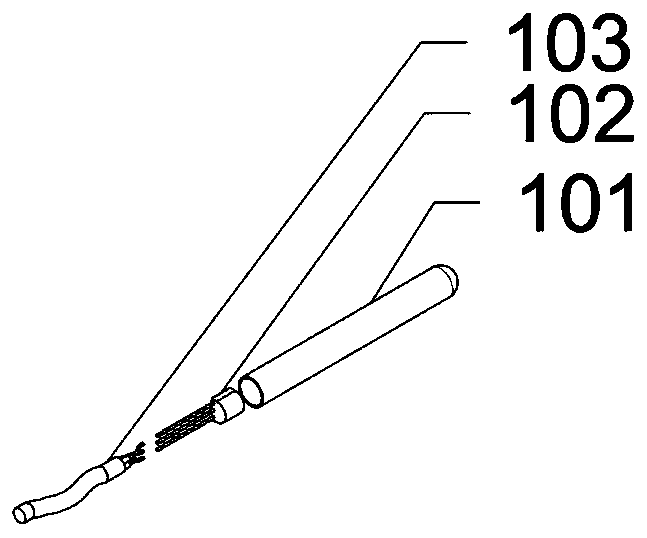

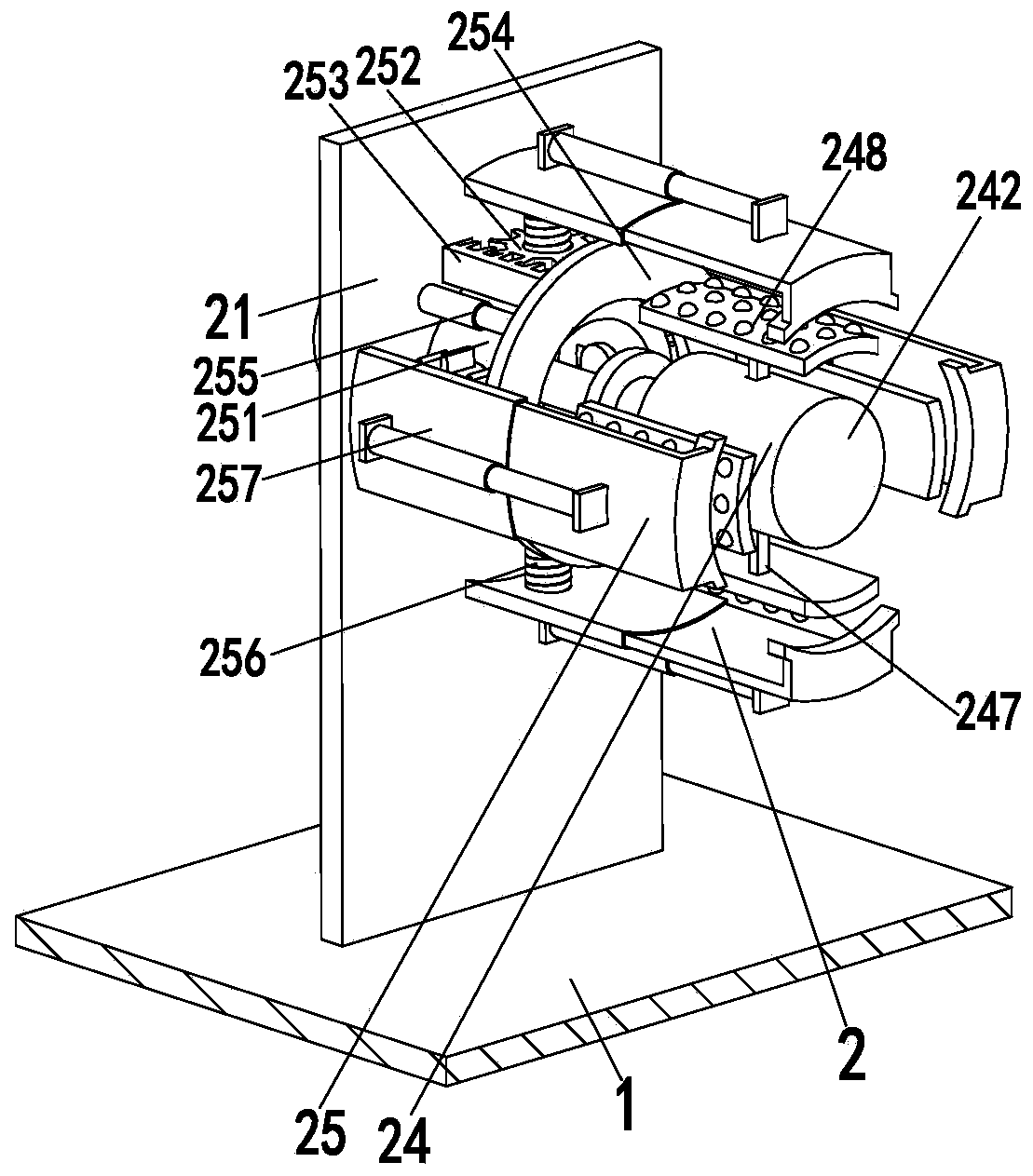

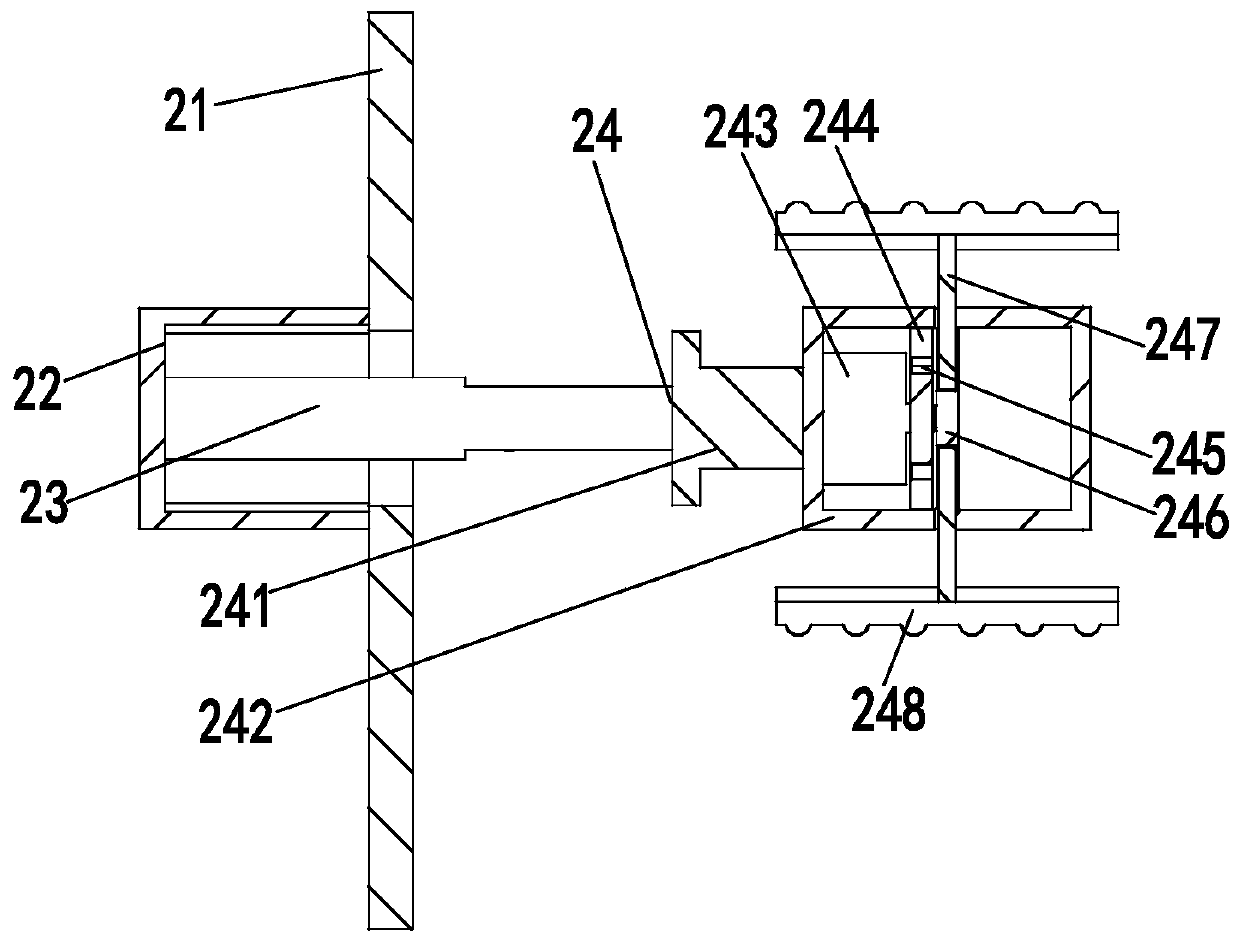

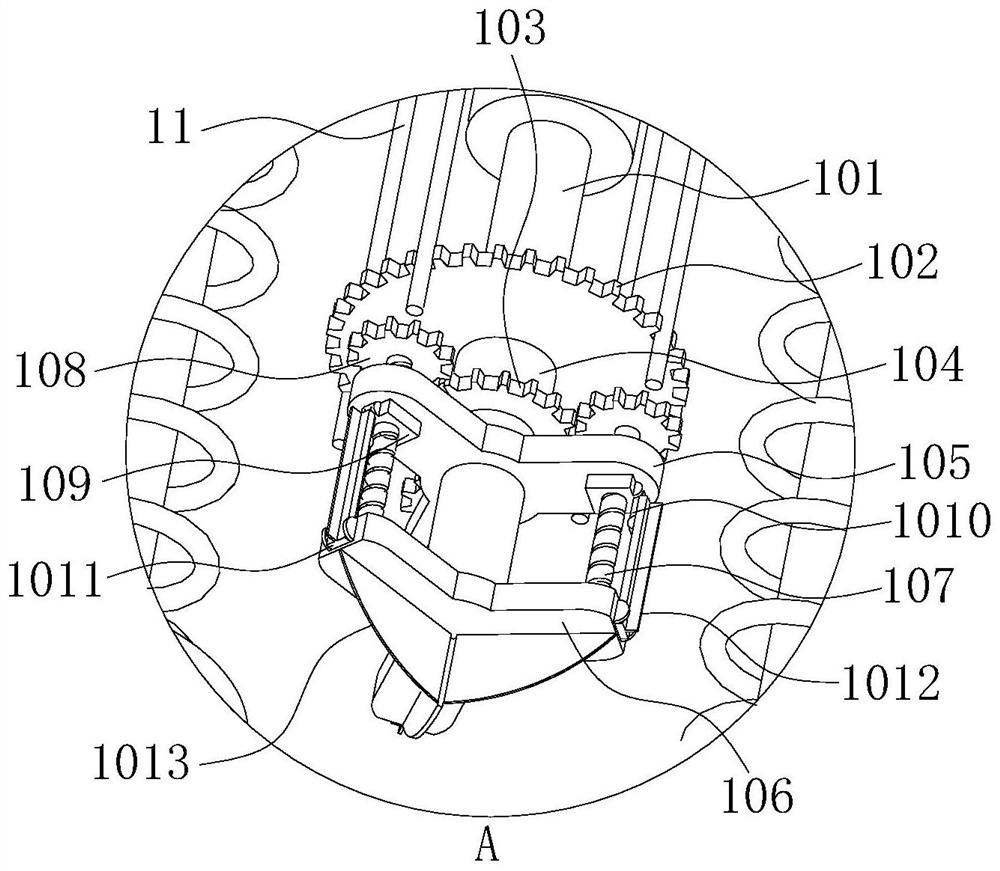

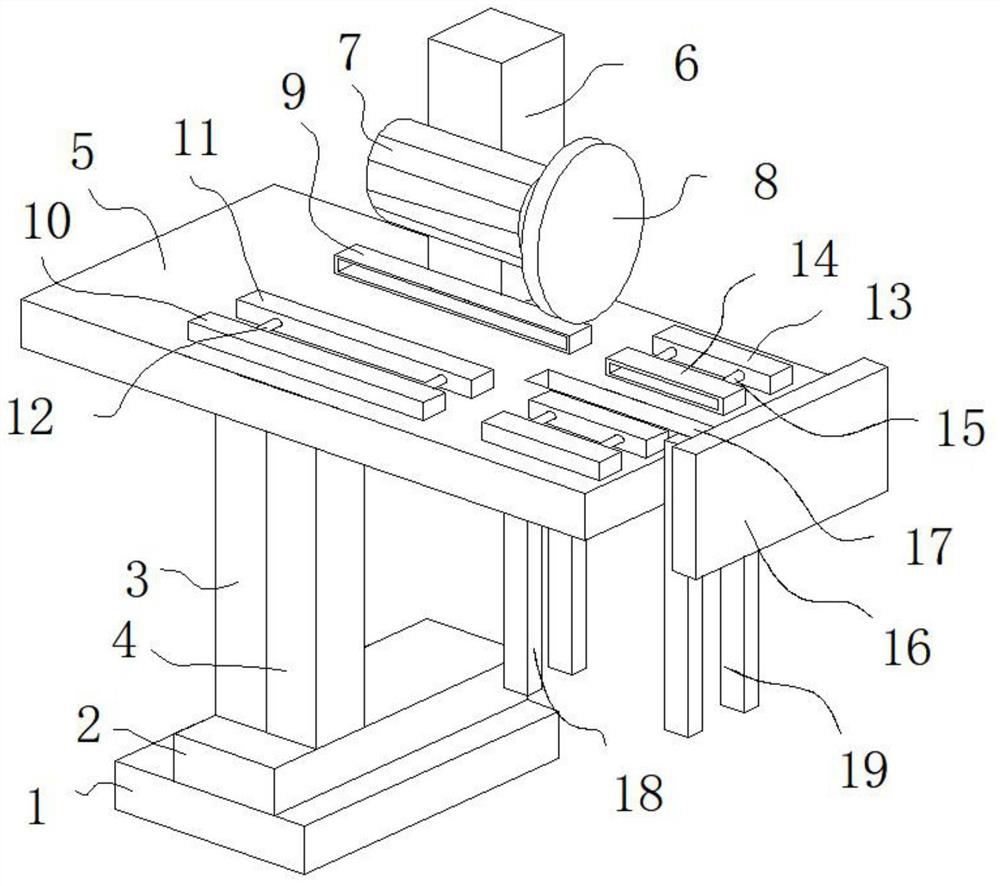

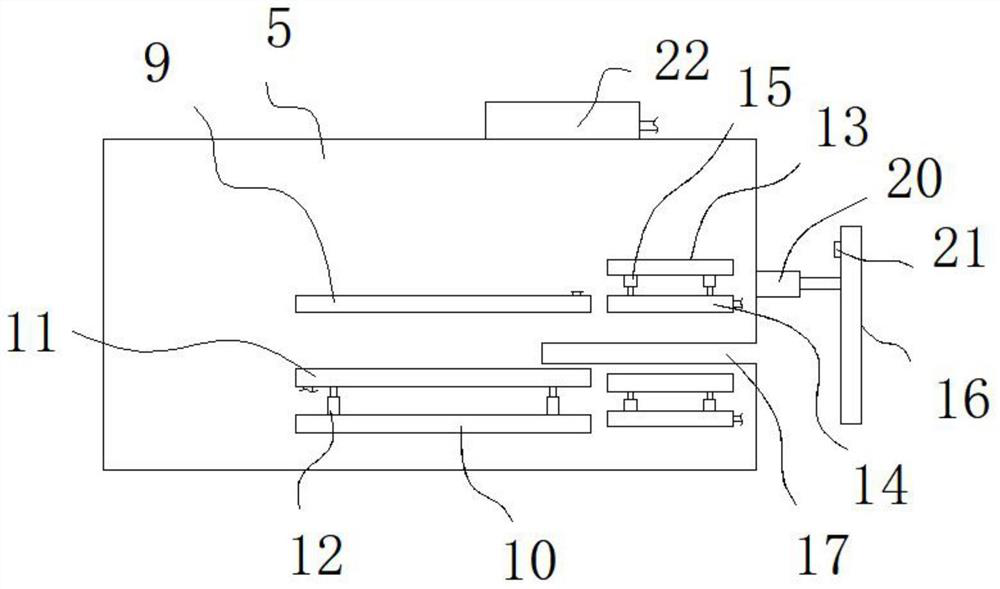

The invention relates to automatic rubber hose cutting equipment and an automatic rubber hose cutting technology. The automatic rubber hose cutting equipment comprises a bottom plate, a supporting device and a cutting device, and the supporting device and the cutting device are sequentially installed on the bottom plate from left to right; the supporting device comprises a fixing plate, a fixed frame, a movable air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the cutting device comprises a linear guide rail, an electric sliding block, a working plate, aworking gear, a driving gear, a driving motor, a rotating ring, a rotating gear, a rotating motor, a supporting air cylinder, a supporting plate, a rotating rod, a sliding frame, a mounting frame, a cutting motor and a cutting blade. The invention further provides a using method of the automatic rubber hose cutting equipment. The equipment and the technology can solve the problems that in an existing rubber hose cutting process, the labor cost is high, the working efficiency is low, the cutting surface is not smooth, safety hidden hazards exist and the surface of a rubber hose is easily scratched, and the function of automatically cutting the rubber hose can be achieved.

Owner:中金液压胶管股份有限公司

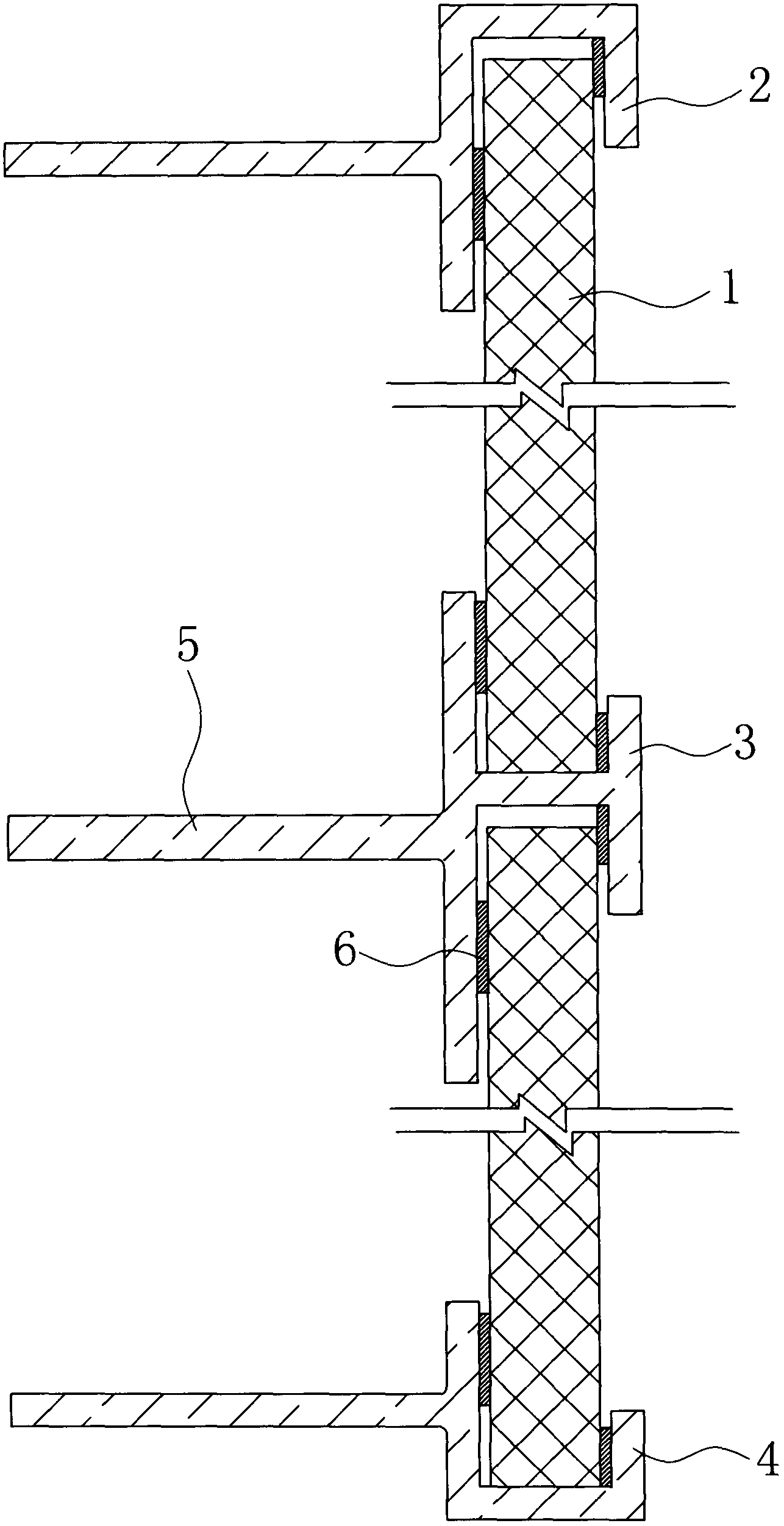

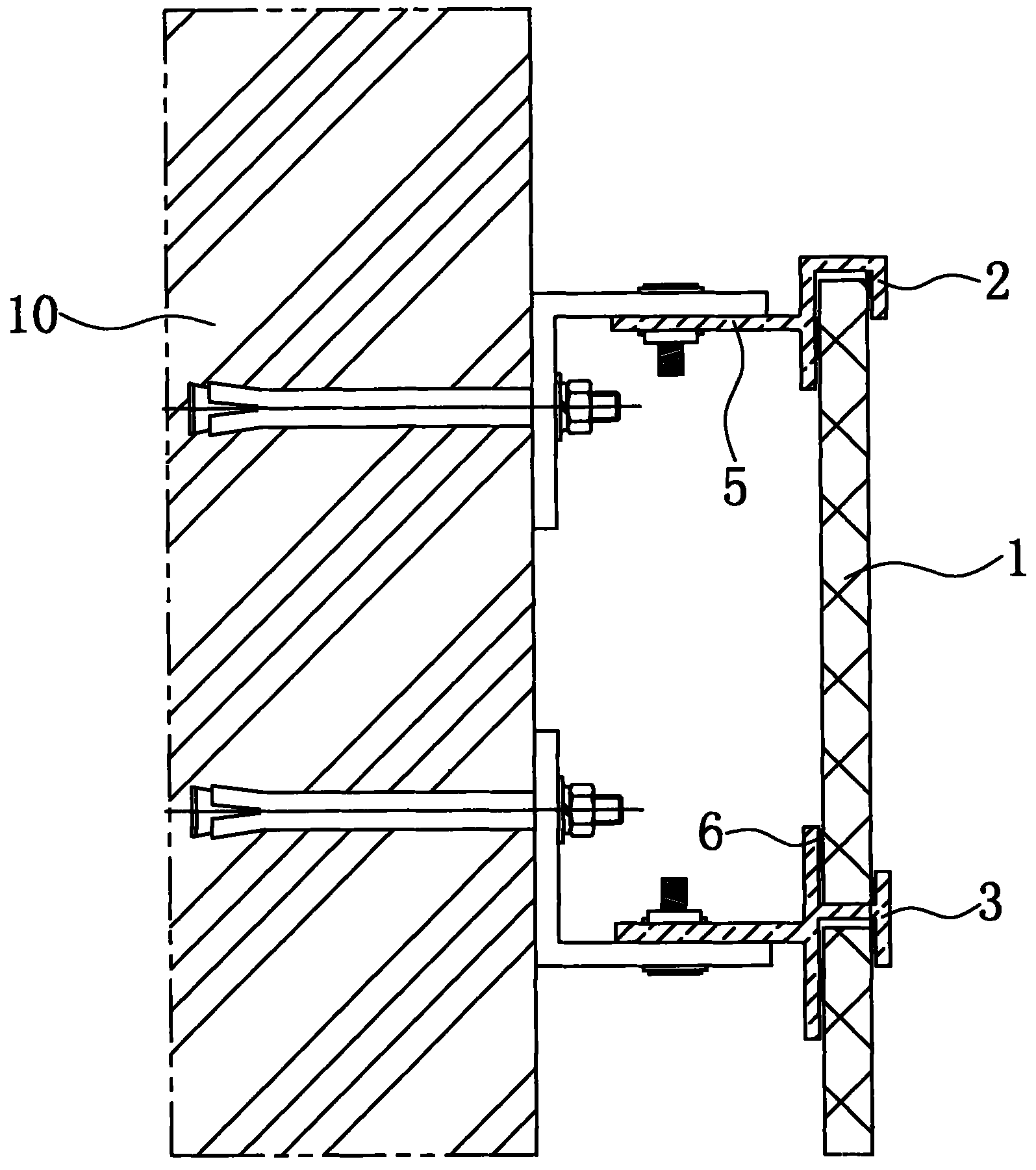

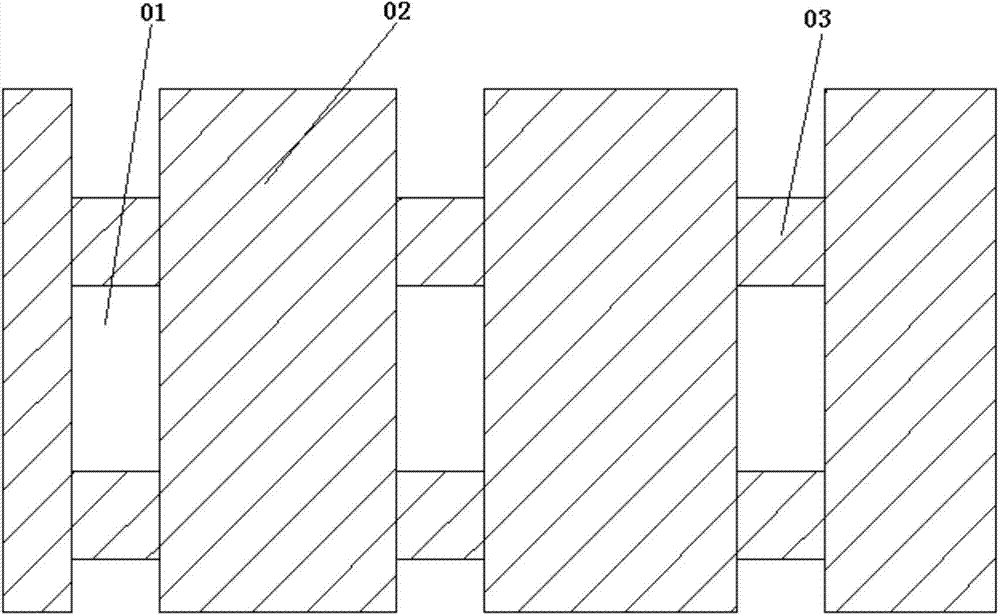

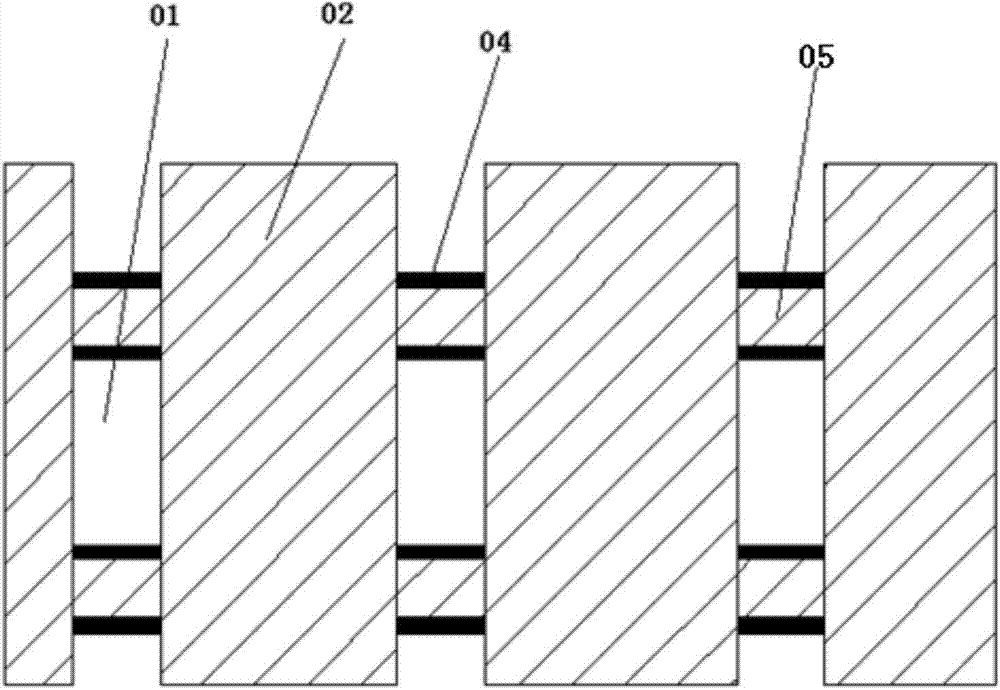

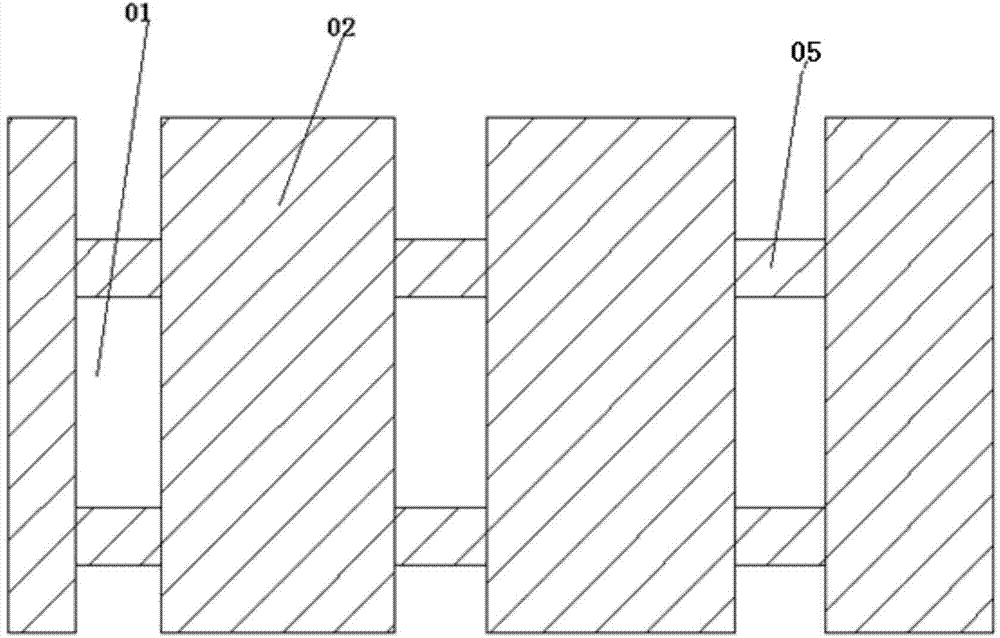

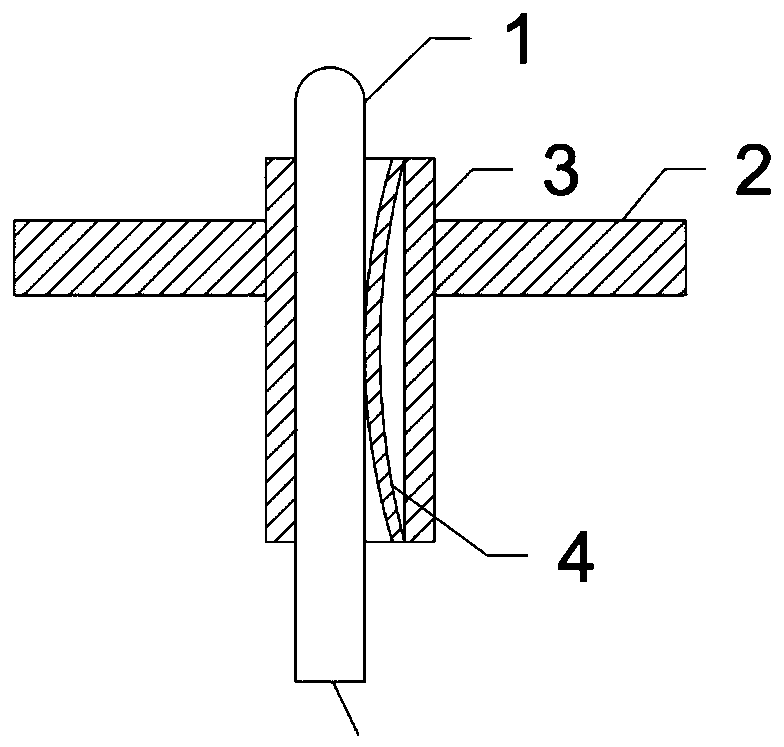

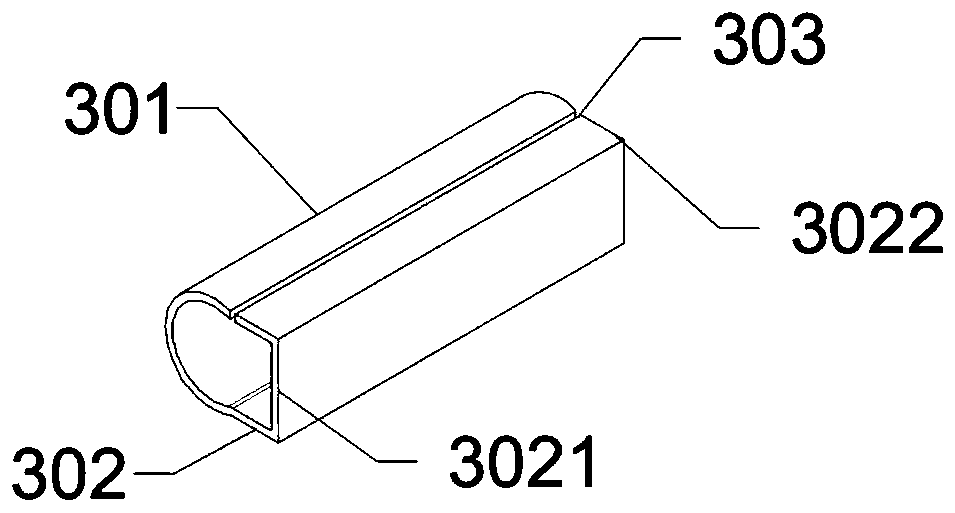

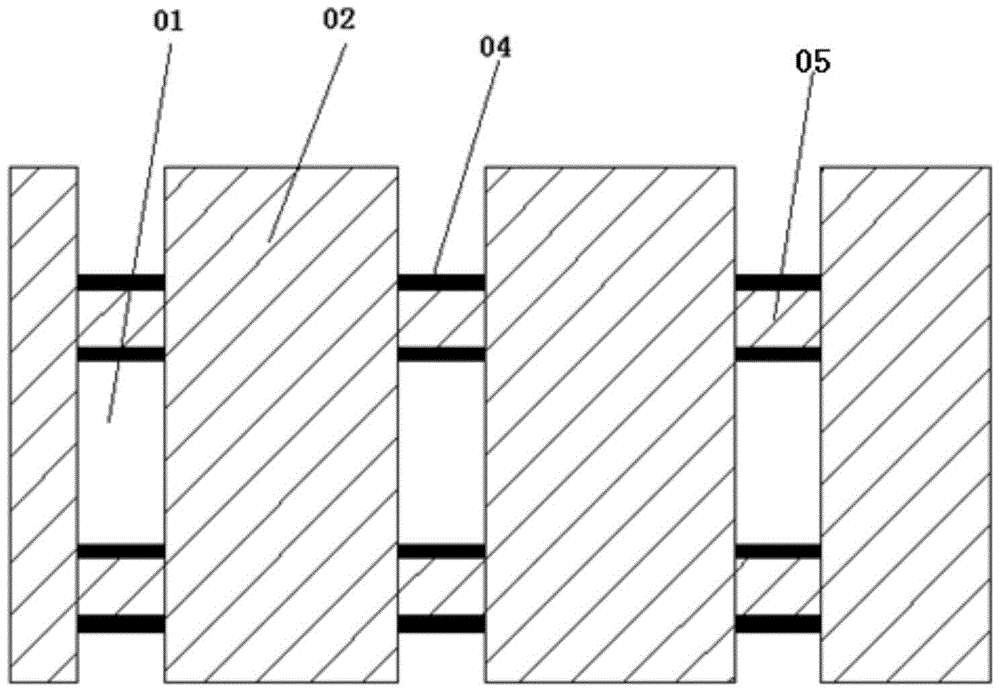

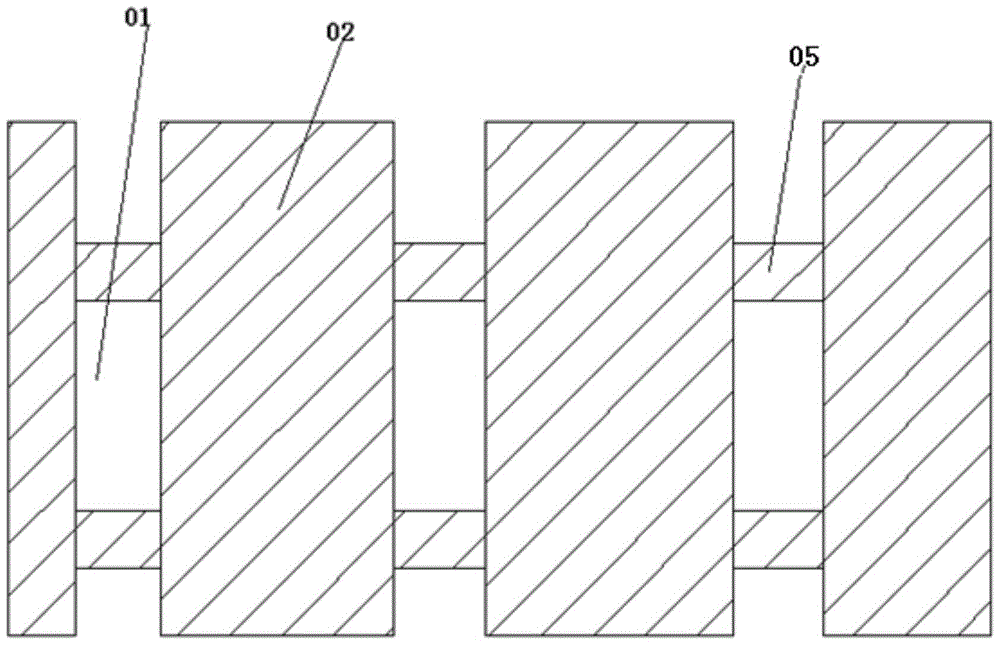

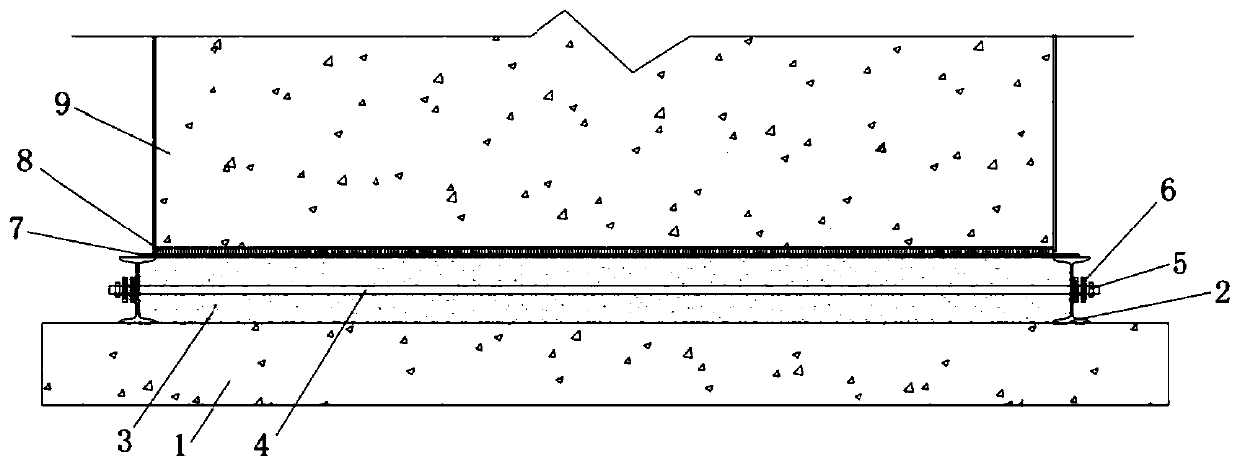

Decorative wall with ultrathin oversized indoor decorating plates and construction method thereof

InactiveCN102691397AEasy to installSuitable for installationCeilingsCovering/liningsChinese charactersKeel

The invention discloses a decorative wall with ultrathin oversized indoor decorating plates. The decorative wall comprises a longitudinal keel assembly, a transverse keel assembly and the decorating plates and is characterized in that the transverse keel assembly consists of an upper keel, at least one middle keel and a lower keel; one ends of the upper and lower keels are respectively provided with an accommodating groove, and the other ends of the upper and lower keels are provided with cross rods connected with the longitudinal keel assembly, so as to form an F shape; the openings of the accommodating grooves of the upper and lower keels are opposite; and one ends of the middle keels are respectively and oppositely provided with an accommodating groove, and the other ends of the middle keels are provided with cross rods connected with the longitudinal keel assembly, so as to form a shape like a Chinese character 'shi'. The method comprises the following steps of: arranging a framework basal layer on a wall main body; arranging the upper keel on the top of the framework basal layer and arranging the lower keel at the bottom of the framework basal layer; arranging the middle keels between the upper keel and the lower keel; and arranging the decorating plates in the accommodating grooves by adopting an upward-insertion and downward-falling manner. According to the decorative wall, by virtue of combining the F-shaped keels and the keels in the shape of a Chinese character 'shi' for use, the ultrathin and oversized decorating plates can be installed; and the construction is convenient and the service life is long.

Owner:苏州苏明装饰股份有限公司

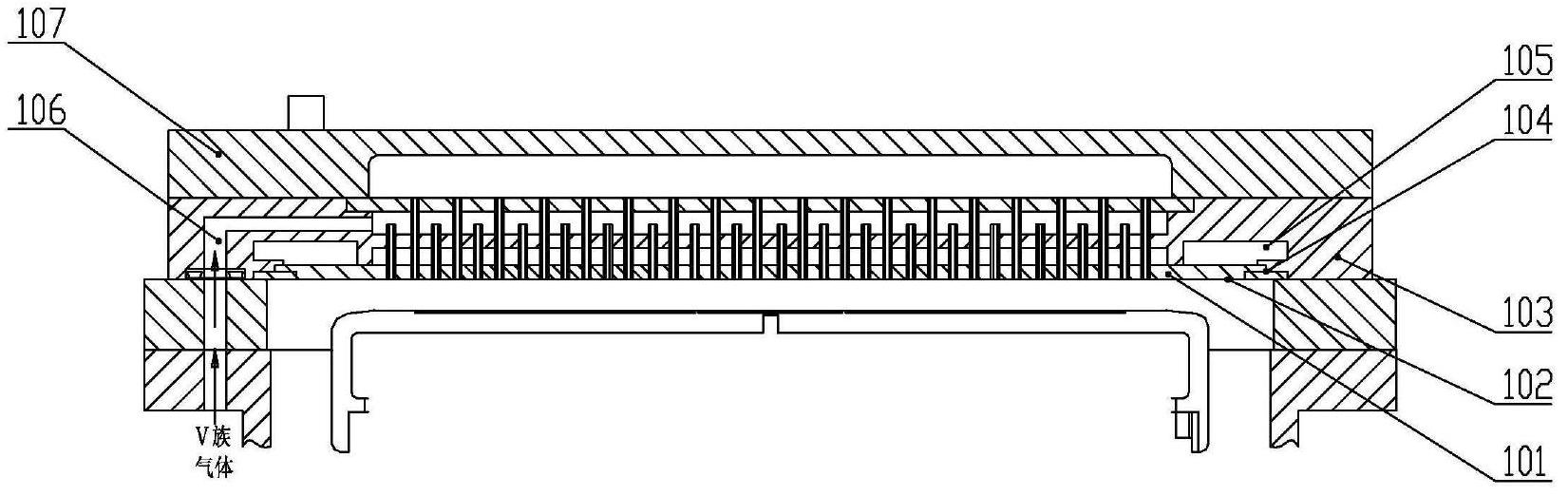

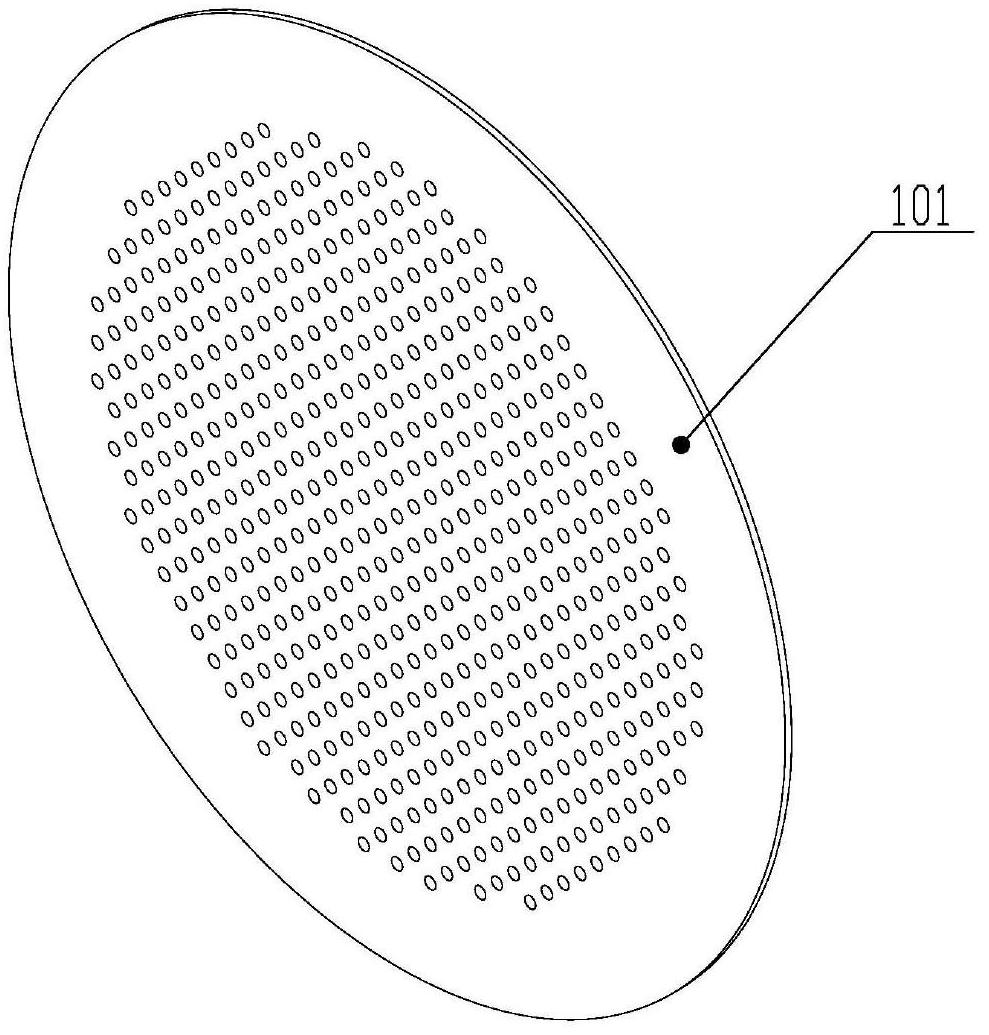

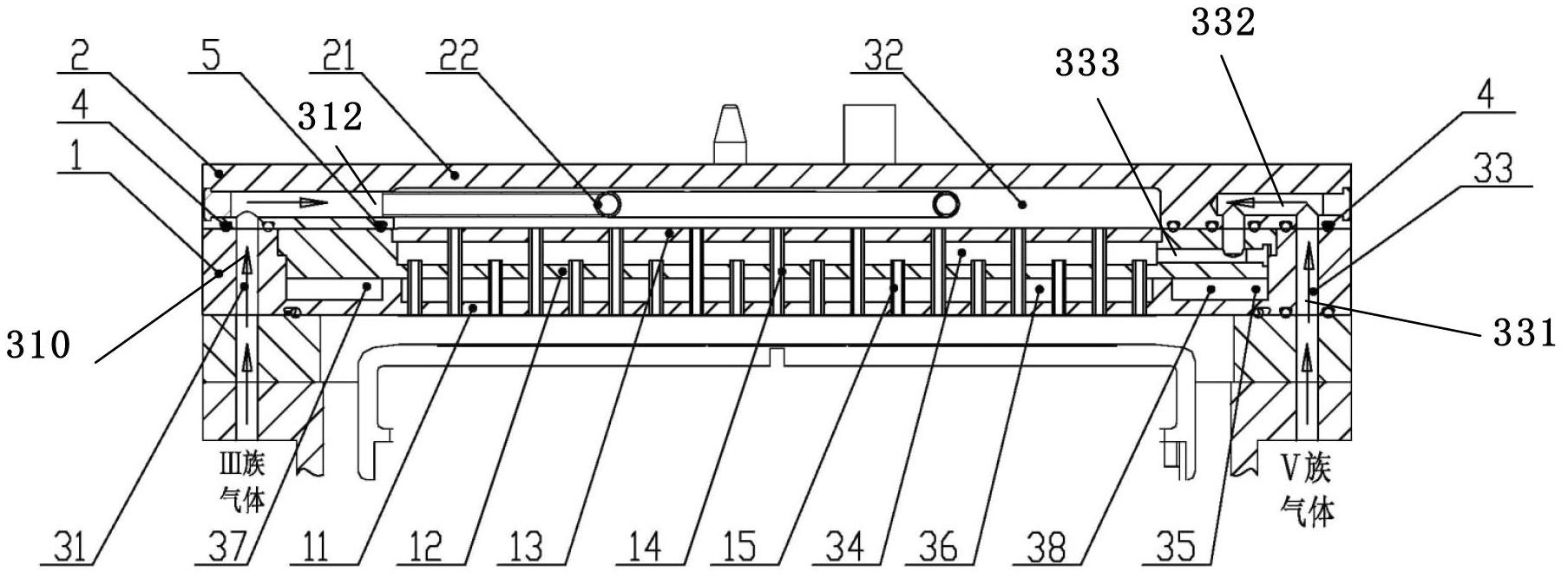

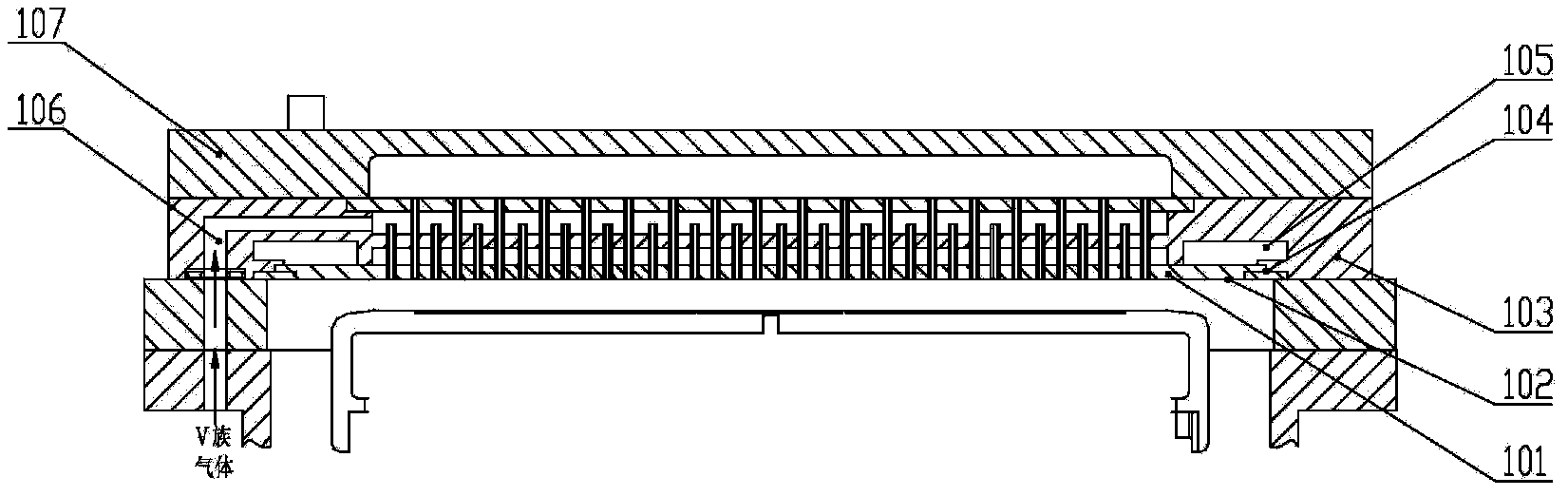

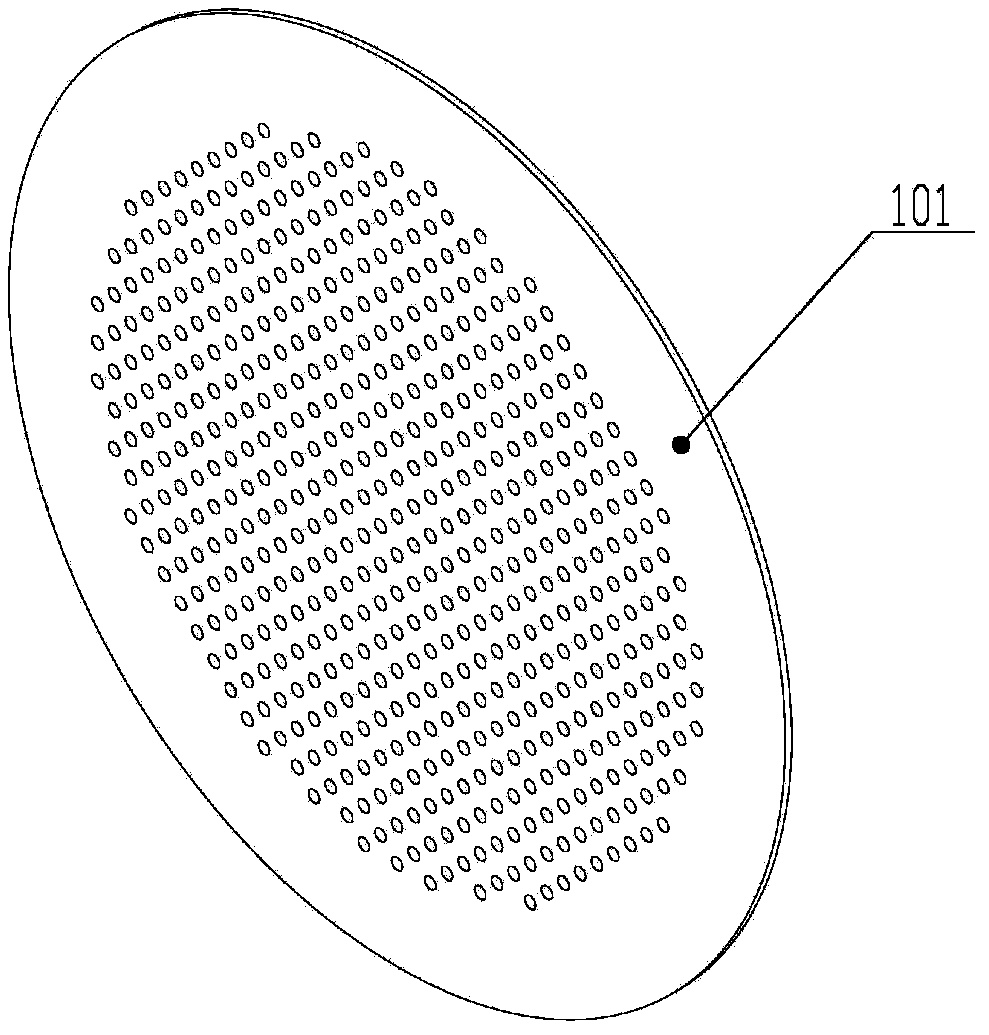

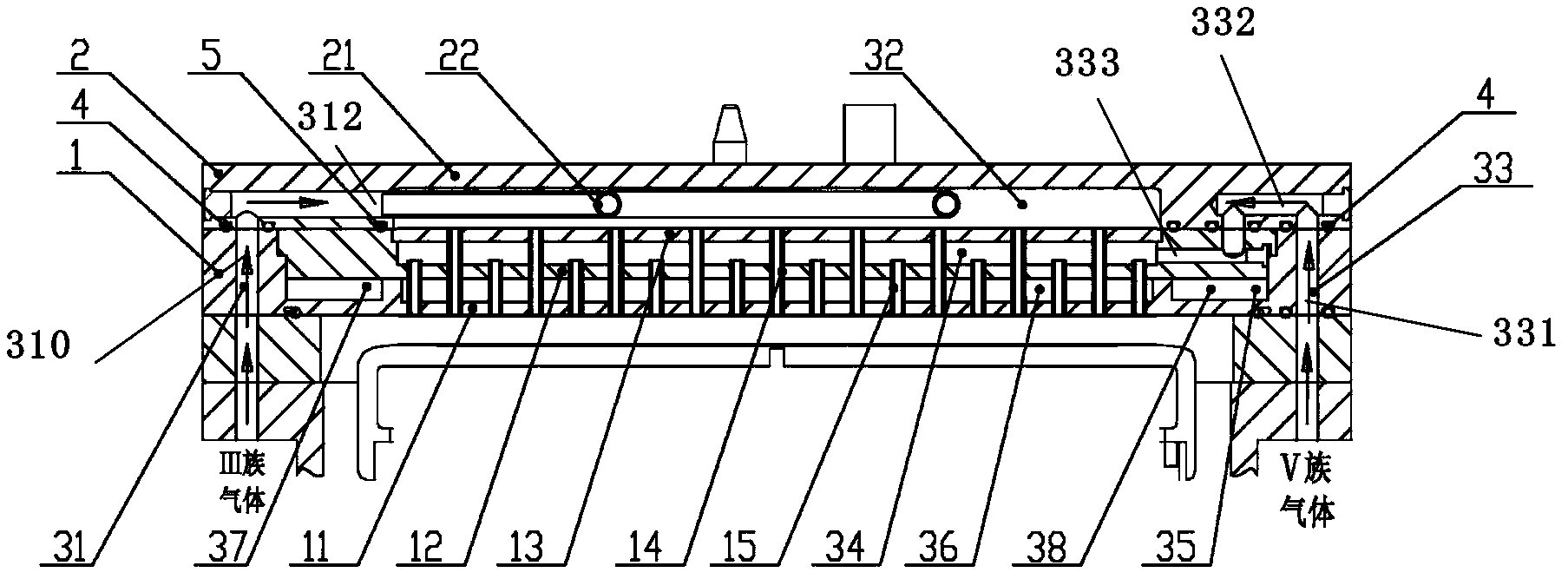

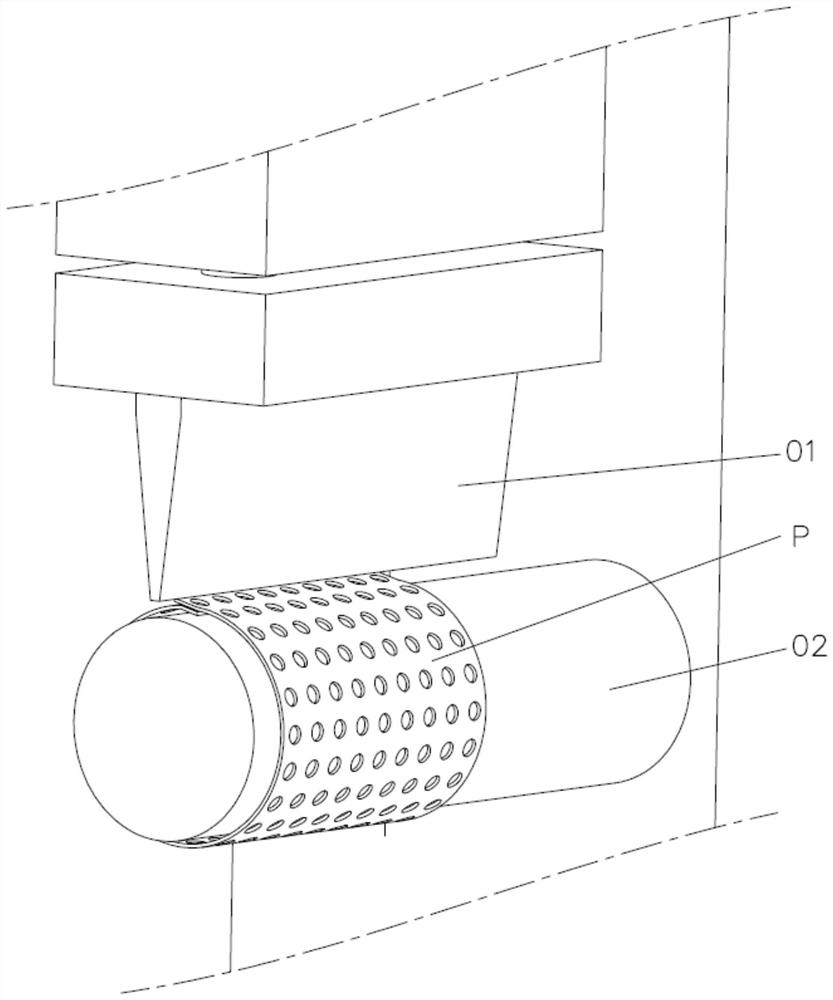

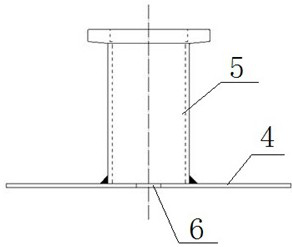

Spray head of MOCVD (metal organic chemical vapor deposition) equipment reactor and connection structure thereof

ActiveCN102691051AHigh strengthFlatness has no effectChemical vapor deposition coatingMetalPlasma-enhanced chemical vapor deposition

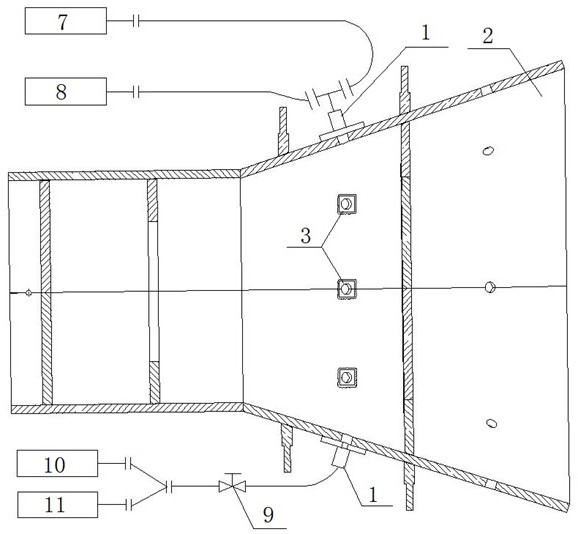

The invention aims to provide a spray head of an MOCVD (metal organic chemical vapor deposition) equipment reactor and a connection structure thereof so as to reduce the adverse influence of welding a bottom layer and a middle layer on a bottom surface. The spray head comprises a spray component and a top cover component, wherein the top cover component comprises a top cover; the spray component comprises a bottom layer, a middle layer and a top layer which are connected together; a cooling water channel and a cooling water cavity are formed between the bottom layer and the middle layer; a V-group gas cavity is formed between the middle layer and the top layer; a III-group cavity is formed between the top layer and the top cover; the bottom layer is an inward-concave integral member which is provided with a bottom wall and a corral side wall protruding from the bottom; and the outer side surface of the middle layer is welded with the inner side surface of the corral side wall of the bottom layer.

Owner:HANGZHOU SILAN AZURE

Powder metallurgy sintering method of non-magnetic steel structural component

The invention relates to a powder metallurgy sintering method of a non-magnetic steel structural component. A powder metallurgy sintering device is adopted for carrying out sintering. The powder metallurgy sintering method comprises the following steps that a green body of the non-magnetic steel structural component is obtained; the powder metallurgy sintering device is provided with a tray used for containing the green body, and sand is laid at the bottom of the tray so as to form a placing sand layer; and the green body is placed on the placing sand layer to be sintered, and the non-magnetic steel structural component is obtained. According to the powder metallurgy sintering method, size changes generated before and after non-magnetic steel structural component sintering can be reduced, and the tolerance of the non-magnetic steel structural component can meet the market requirement.

Owner:GUANGDONG YUEHAI HUAJIN TECH CO LTD

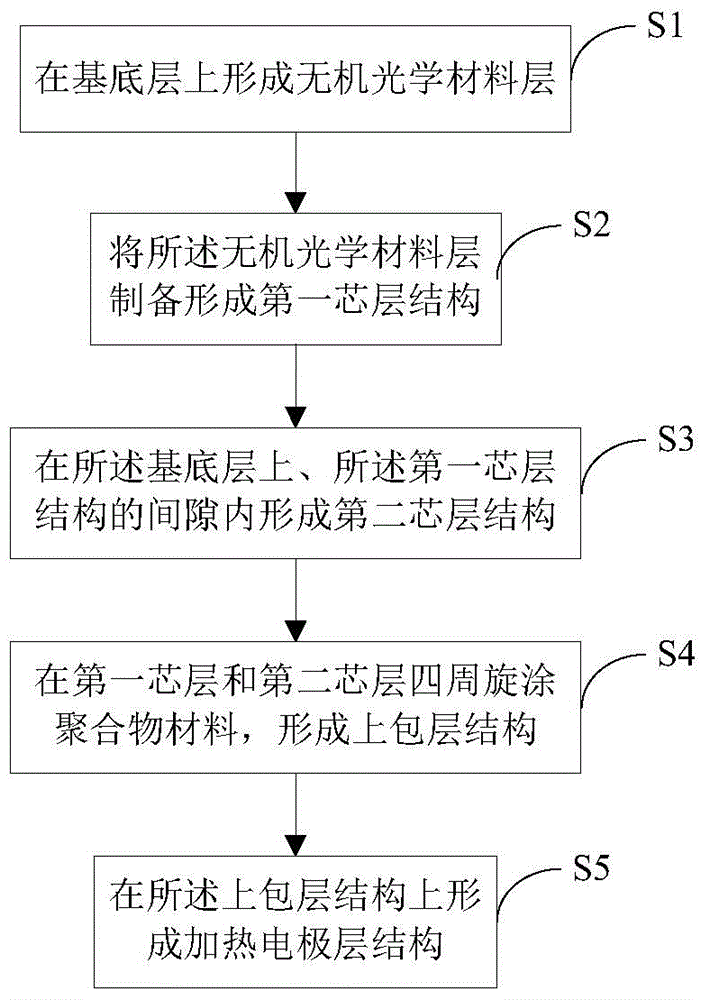

Organic-inorganic hybrid integrated thermo-optical modulation type grating and preparation method thereof

InactiveCN105759349AAvoid crackingEffect of flatnessOptical waveguide light guideGratingWavelength modulation

The invention discloses an organic-inorganic hybrid integrated thermo-optical modulation type grating and a preparation method thereof. The grating comprises a substrate layer which employs an inorganic optical material; a core layer which is formed on the substrate layer and comprises a first core layer and a second core layer alternatively arranged along a light spreading direction, wherein the first core layer employs an inorganic optical material, and the material of the second core layer comprises an ultraviolet convergent type fluorinated polymer material; an upper wrapping layer which is formed at the periphery of the core layer and employs a polymer material; and a heating electrode layer which is formed on the upper wrapping layer. The organic-inorganic hybrid integrated thermo-optical modulation type grating and the preparation method thereof can realize low-loss large-scope wavelength modulation.

Owner:苏州峰通光电有限公司

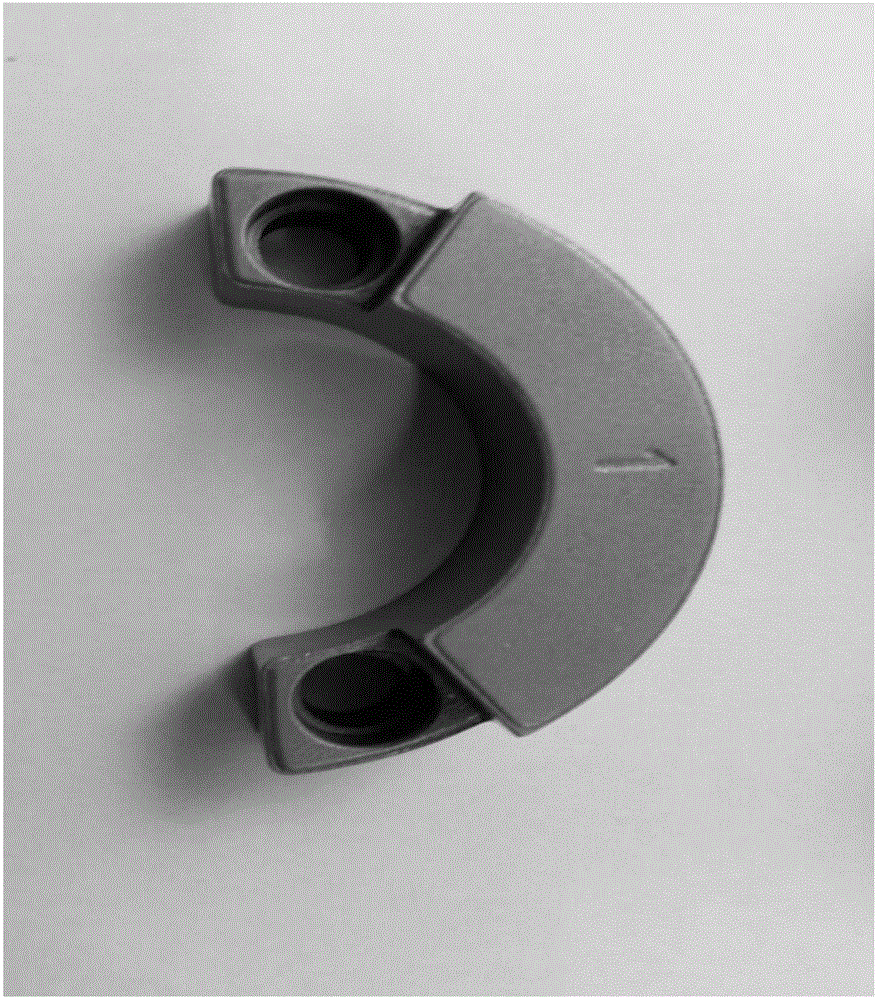

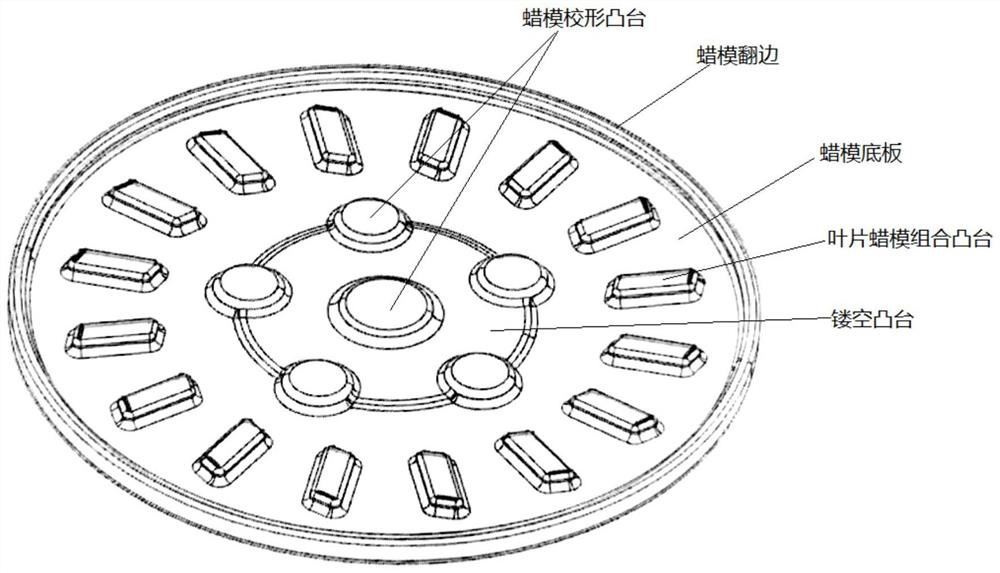

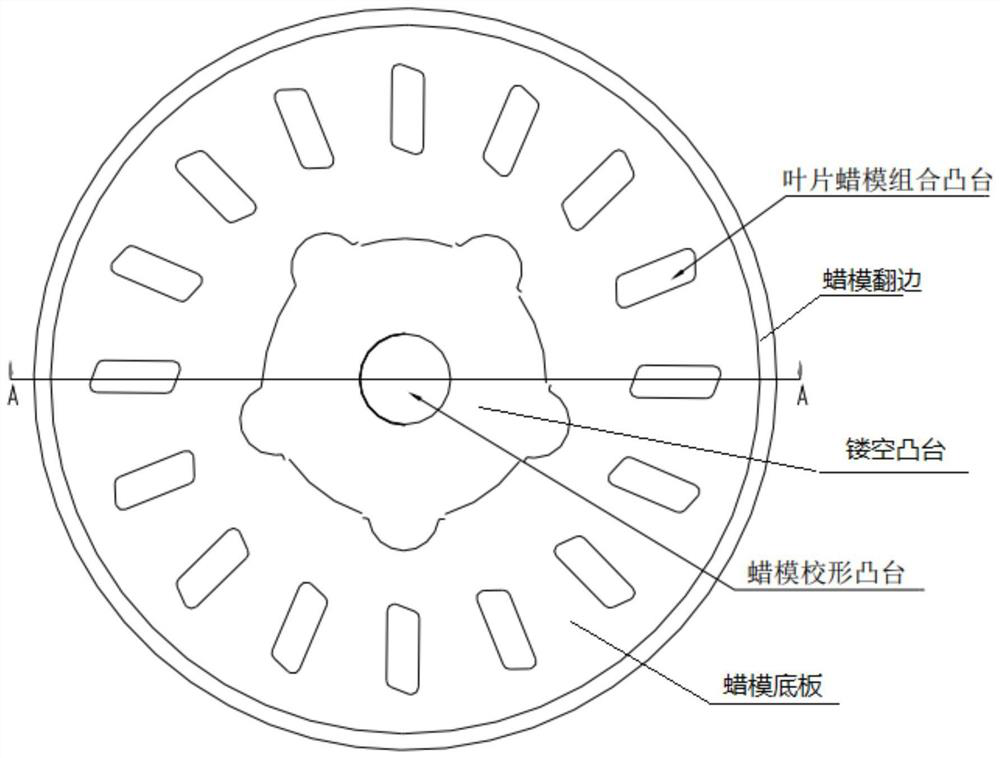

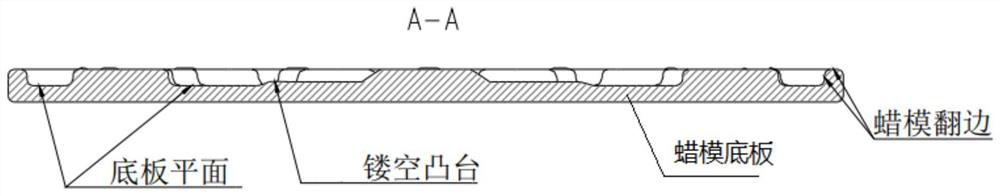

Bottom plate wax mold structure and forming method of directional solidification shell bottom plate

ActiveCN113926988APrevent shrinkage deformationEffect of flatnessFoundry mouldsFoundry coresCircular discEngineering

The invention discloses a bottom plate wax mold structure and a forming method of a directional solidification shell bottom plate. The bottom plate wax mold structure is characterized in that a plurality of annularly distributed blade wax mold combination bosses are arranged on a flat disc-shaped wax mold bottom plate, and therefore welded and fixed on a plurality of blade wax molds when a module is assembled into a tree; and a welding seam is moved out of a plane of the wax mold bottom plate, so that the influence of the welding seam on flatness of a plane of the shell bottom plate is avoided. Meanwhile, a wax mold shape correction boss is arranged in a central area of the wax mold bottom plate and serves as an acting point for wax mold shape correction, stress is transmitted from the center to the periphery during shape correction, shrinkage deformation of the whole bottom plate wax mold can be effectively prevented, and then the bottom surface flatness and the circumference regularity during molding of the shell bottom plate are guaranteed. Moreover, the hollow boss is arranged in the middle area of the wax mold bottom plate, so that the plane area of the bottom surface of the directional solidification shell bottom plate can be reduced, and the problem that the bottom surface of the directional solidification shell bottom plate is uneven due to the fact that the wax mold bottom plate is sunken in the middle due to pressure is solved.

Owner:CHINA HANGFA SOUTH IND CO LTD

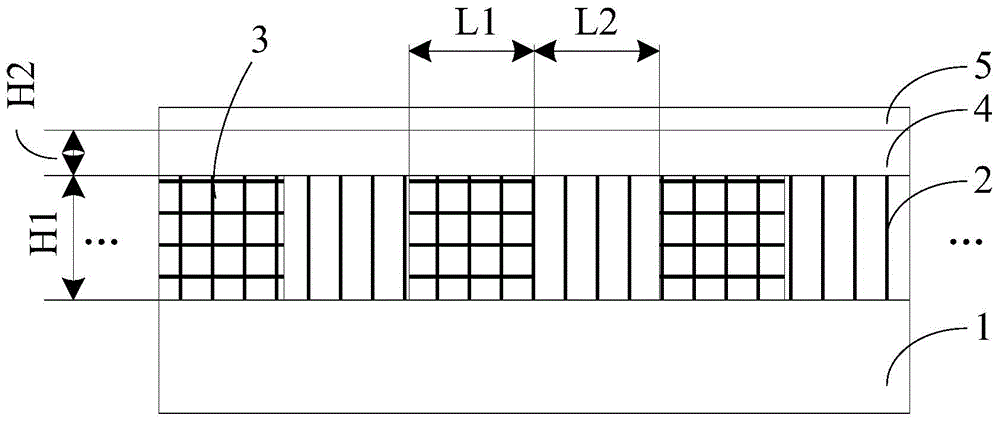

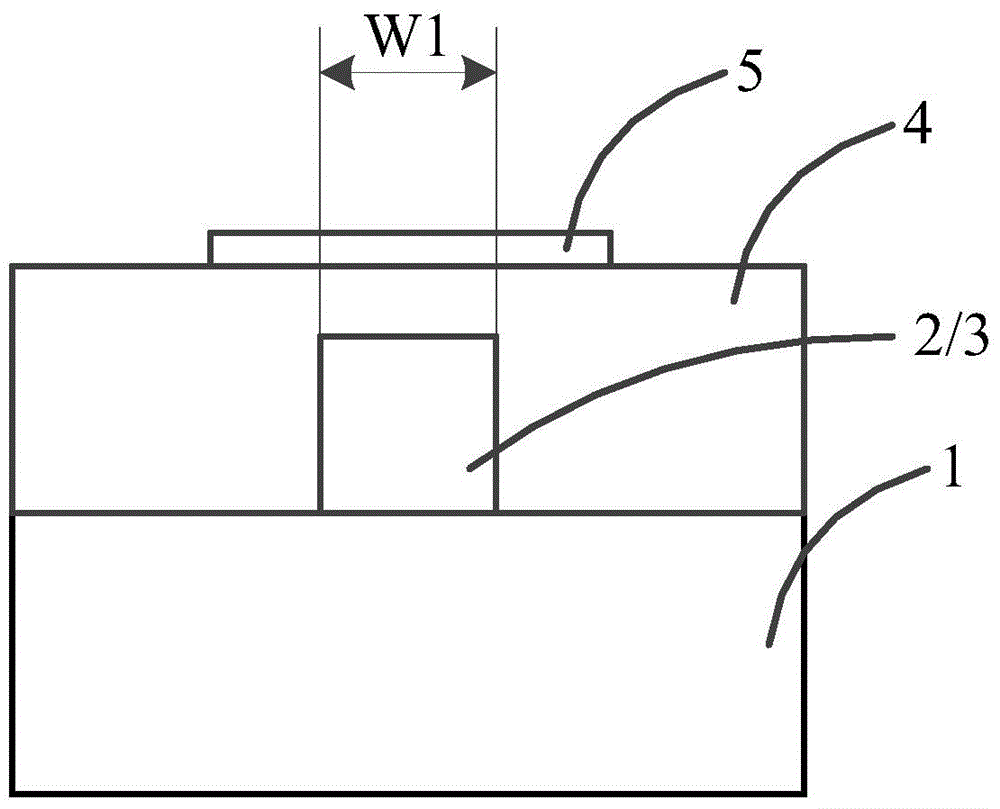

Preparation method of high-opening-ratio mask board and mask board

ActiveCN104505471AReduce widthIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingBody regionEngineering

The invention provides a preparation method of a high-opening-ratio mask board. The preparation method comprises the following steps: step 1, coating a photo-curing material on the surface of the mask board; performing ultraviolet irradiation and curing on the photo-curing material in a mask board main body region and in a connecting bridge retention region to form a low polymer; washing and removing the uncured photo-curing material from the surface of a to-be-corroded region of a connecting bridge, then soaking the mask board of which the surface is coated with the low polymer into a corrosive solution to remove the to-be-corroded region of the connecting bridge so as to obtain the mask board of which the surface is coated with the low polymer; step 2, removing the low polymer from the surface of the mask board to obtain the high-opening-ratio mask board. By reducing the width of the connecting bridge of the mask board main body, the opening ratio of the mask board can be effectively increased and can be increased by 30% to 50% specifically.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

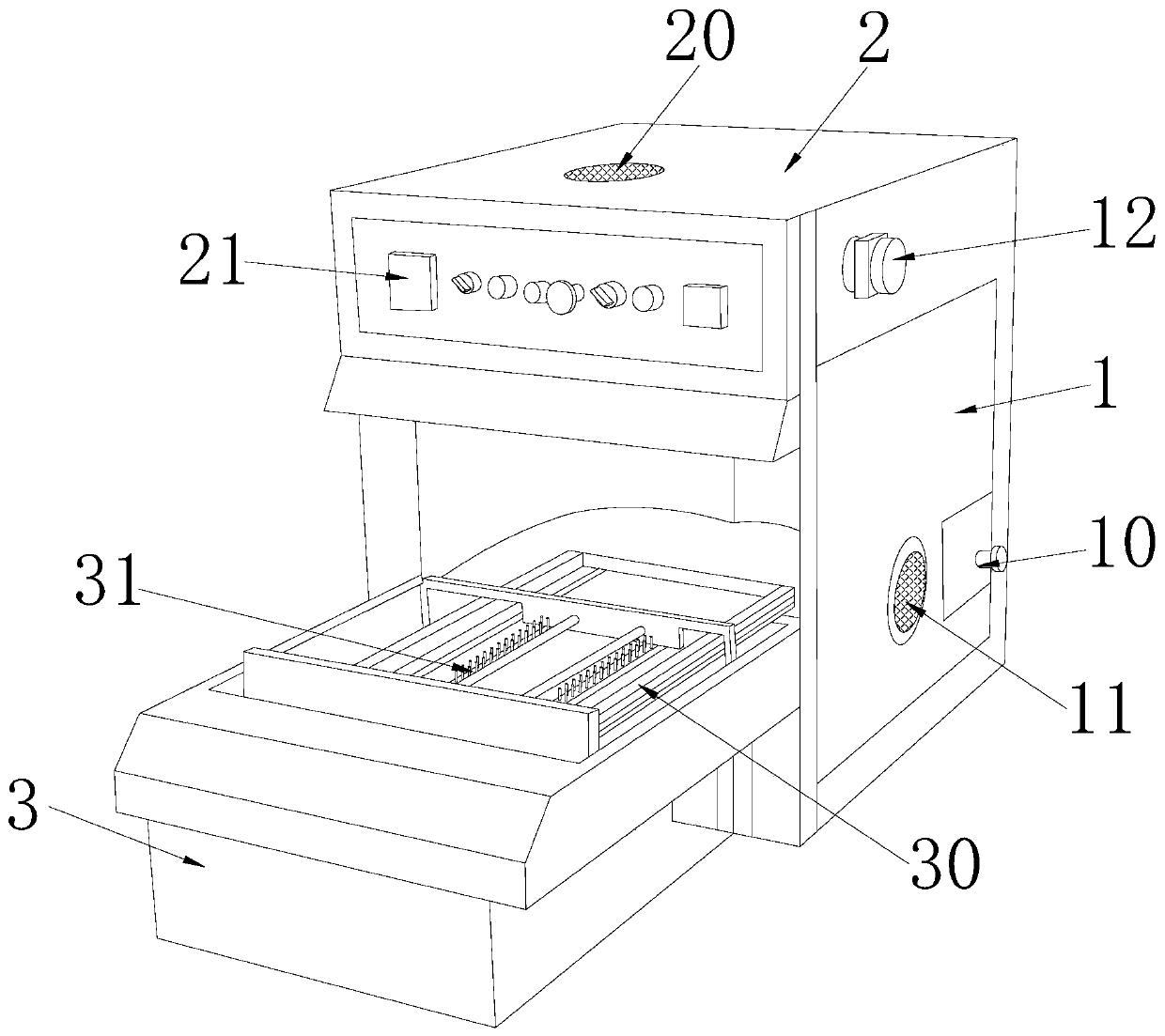

Printing and dyeing equipment for washable textile fabric

ActiveCN110485097AGuaranteed to workEffect of flatnessMechanical cleaningPressure cleaningEngineeringTextile dye

The invention discloses printing and dyeing equipment for washable textile fabric. The printing and dyeing equipment structurally comprises a main body, a controller and a workbench; the main body isprovided with a positive and negative regulator, a radiator and a switch; the controller is provided with a fan and a control panel; the workbench is provided with a needle plate frame and a needle rod wool remover. The printing and dyeing equipment has the advantages that an ejection plate can be pushed to move upwards under the driving of pressers, a wool removal net is also pushed upwards whenthe ejection plate moves upwards, then, fine thread on the upper surface of the wool removal net is pushed to be separated from the ejection plate, as the wool removal net is a soft net and the fine thread is light, the ejection plate moves downwards when press rods are pressed back to the original position, the wool removal net and the thin thread can suspend on the tops of carding needles, at the moment, the wool removal net can be detached simply by slightly pulling pull rods upwards, fine thread cleaning is conducted, the wool removal net is installed on the carding needles again after cleaning, and reuse is realized; the fine thread is easily cleaned away, so that the normal work of the needle plate frame is guaranteed, and meanwhile it is guranateed that the flatness of the fed fabric is not affected.

Owner:佛山市汇灏纺织科技有限公司

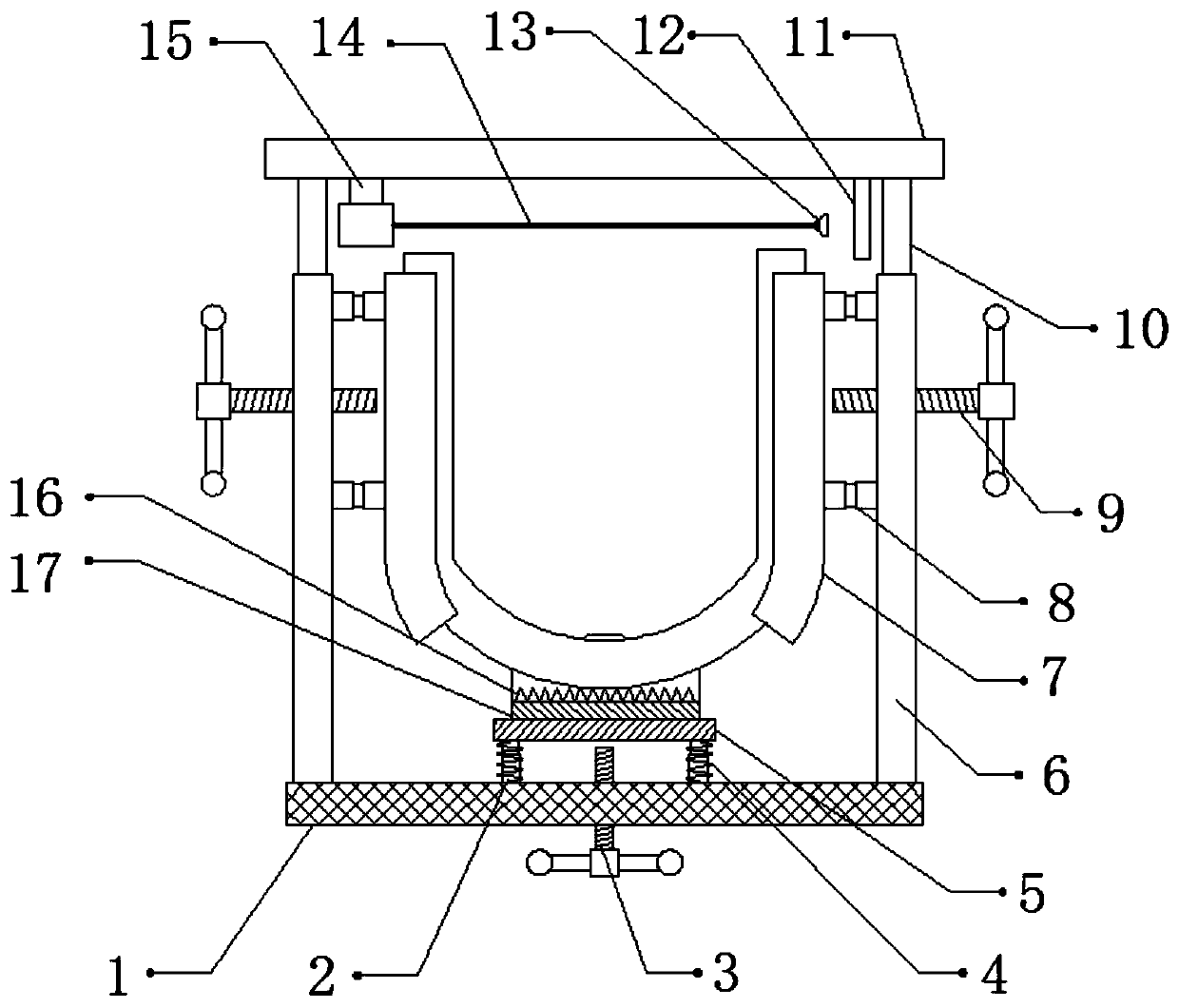

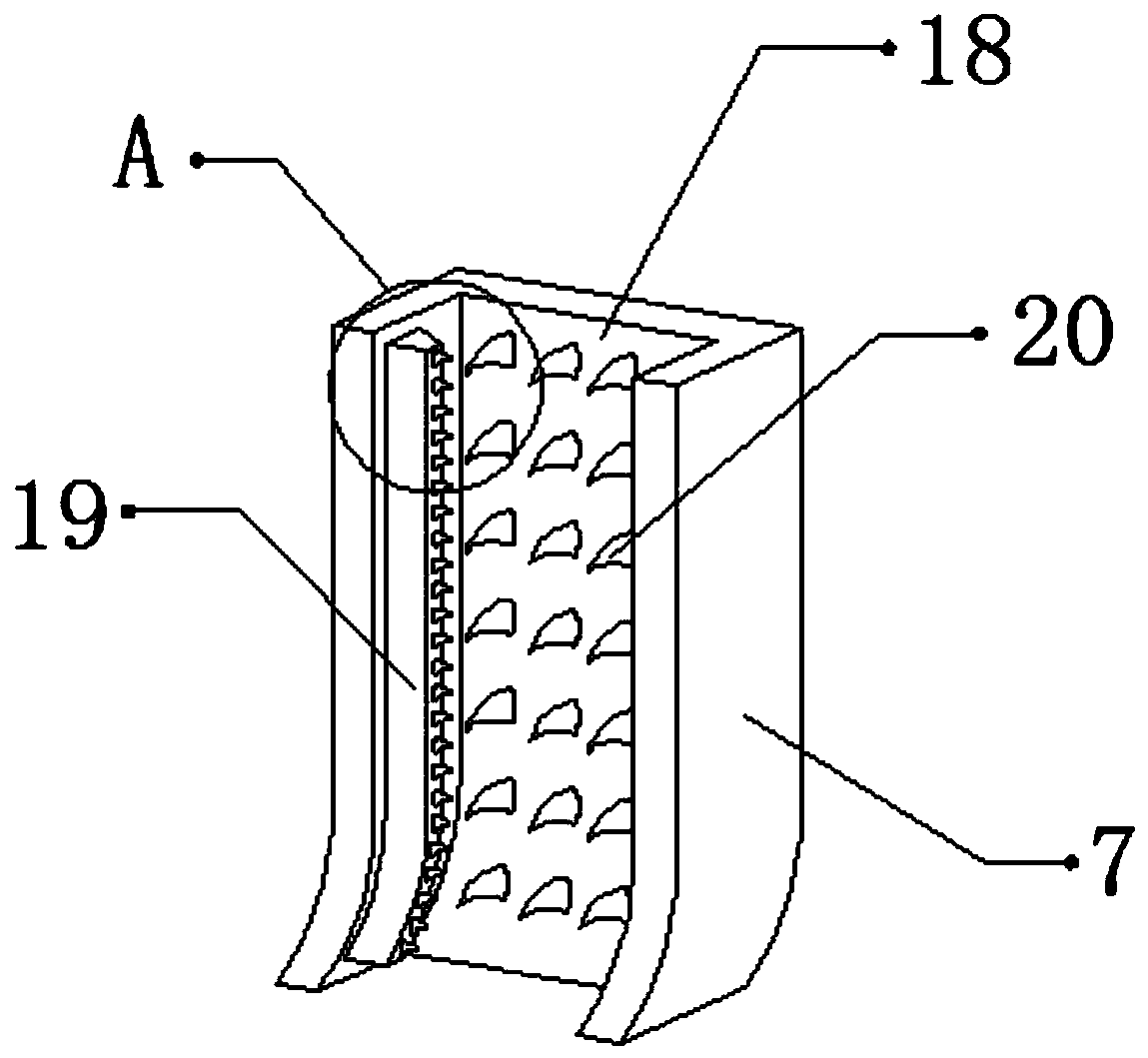

Detection device for pipe fitting production

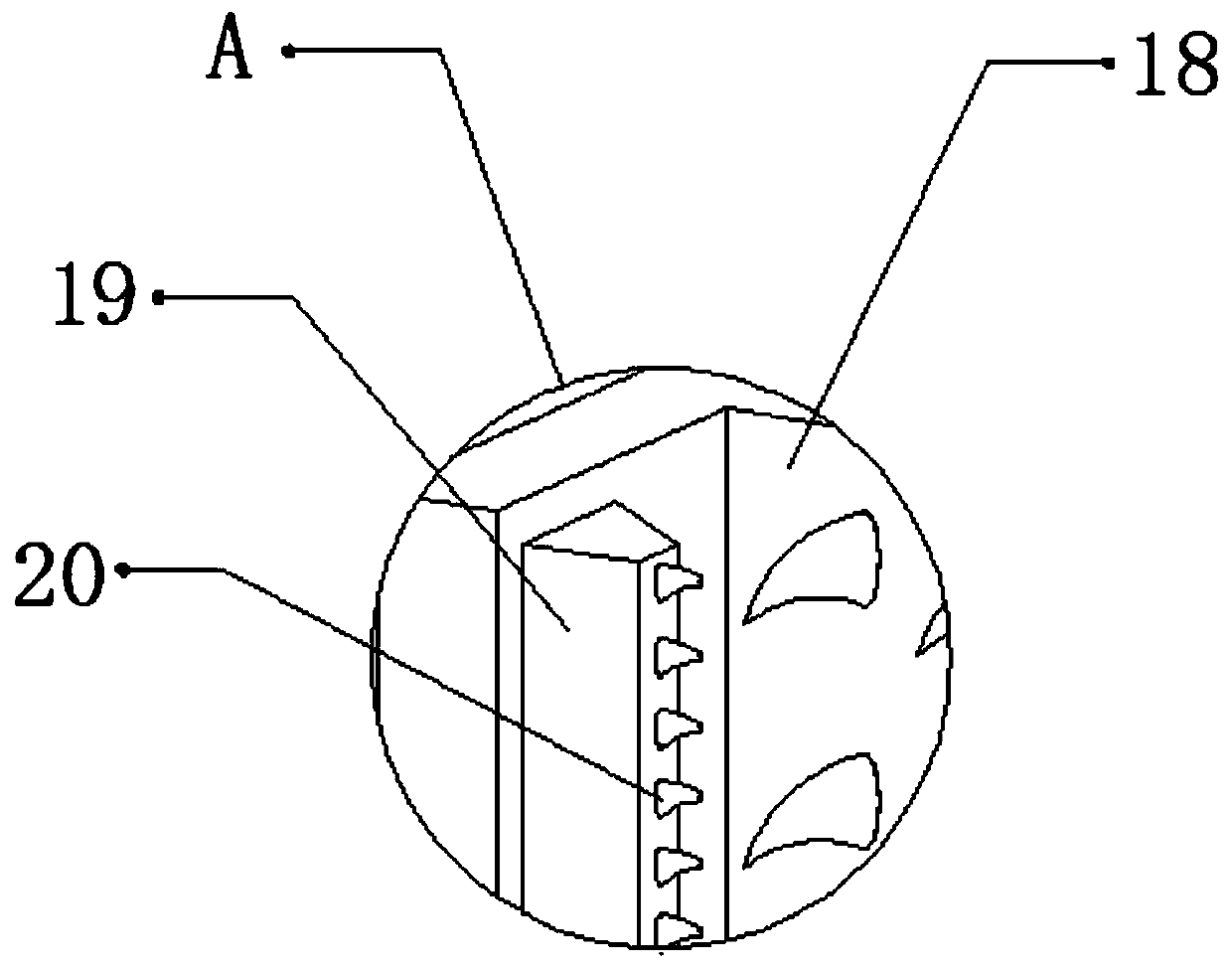

PendingCN111288878AEasy to detect and handleAvoid breakageMechanical roughness/irregularity measurementsPrimary canine toothProtruding tooth

The invention discloses a detection device for pipe fitting production. The device comprises a fixed base, and fixing rods are fixed to the two sides of the outer wall of the top of the fixed base. Two second telescopic rods are fixed on the outer walls of the opposite sides of the two fixed rods; a clamping plate is fixed to the outer wall of one side of the second telescopic rod. Fixing groovesare formed in the outer walls of the opposite sides of the two clamping plates, restraining plates are bonded to the inner walls of the opposite sides of the fixing grooves, a plurality of convex teeth distributed at equal intervals are arranged on the outer walls of the sides of the restraining plates and the inner walls of the sides of the fixing grooves, wherein the convex teeth are in a caninetooth shape; and fixing shafts are fixed to the outer walls of the tops of the two fixing rods. According to the detection device, a U-shaped pipe is prevented from sliding off from the clamping plate and thus the deviation of detection data of the U-shaped pipe is avoided, the U-shaped pipe is prevented from sliding off to influence detection of the U-shaped pipe, and the clamping plate is prevented from clamping the U-shaped pipe with large force to damage the surface of the U-shaped pipe.

Owner:上海派腾特商务咨询有限公司

Road engineering pavement leveling machine

InactiveCN114381987AEffect of flatnessSolve the problem of difficult compaction and levelingMechanical machines/dredgersRoads maintainenceRoad engineeringArchitectural engineering

The invention discloses a road engineering pavement leveling machine, and belongs to the technical field of pavement leveling. A road engineering pavement leveling machine comprises a moving seat, a collecting groove is formed in the advancing side of the moving seat, and the advancing side of the collecting groove and the moving seat are fixedly connected with a shovel plate; a rolling shaft is rotatably arranged on the side, close to the shovel plate, in the collecting tank, and a plurality of soil breaking wheels are fixedly arranged on the rolling shaft; a plurality of leaking holes are formed in the bottom wall of the collecting tank; a rolling wheel is further rotationally arranged at the bottom of the moving base and arranged on the side, away from the rolling shaft, of the collecting groove. According to the device, the uneven position of the roadbed can be flexibly repaired and leveled in a targeted mode, the guarantee for the flatness of the roadbed is greatly enhanced, operation is easy, use is convenient, and the convenience degree is high.

Owner:吴丹丹

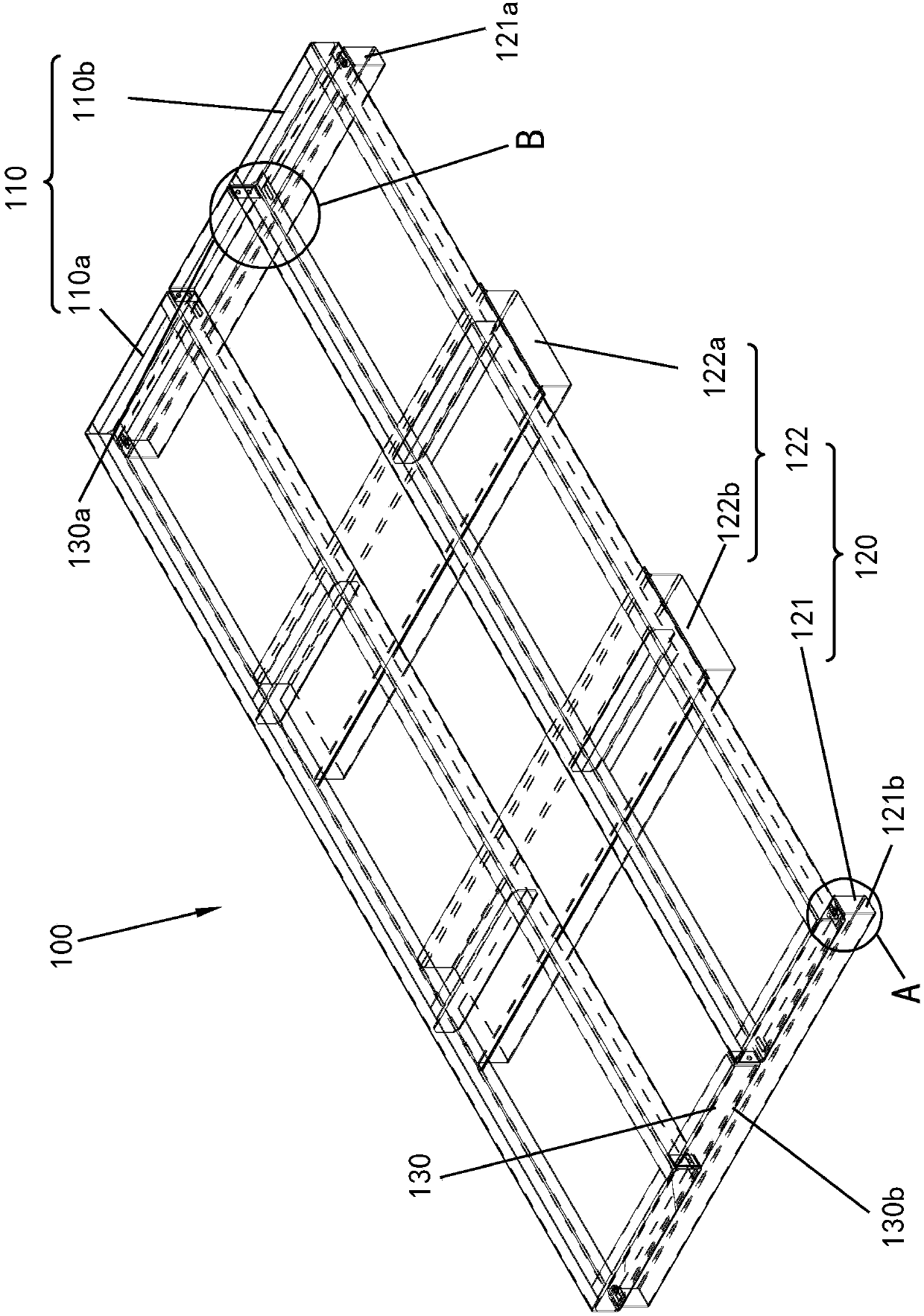

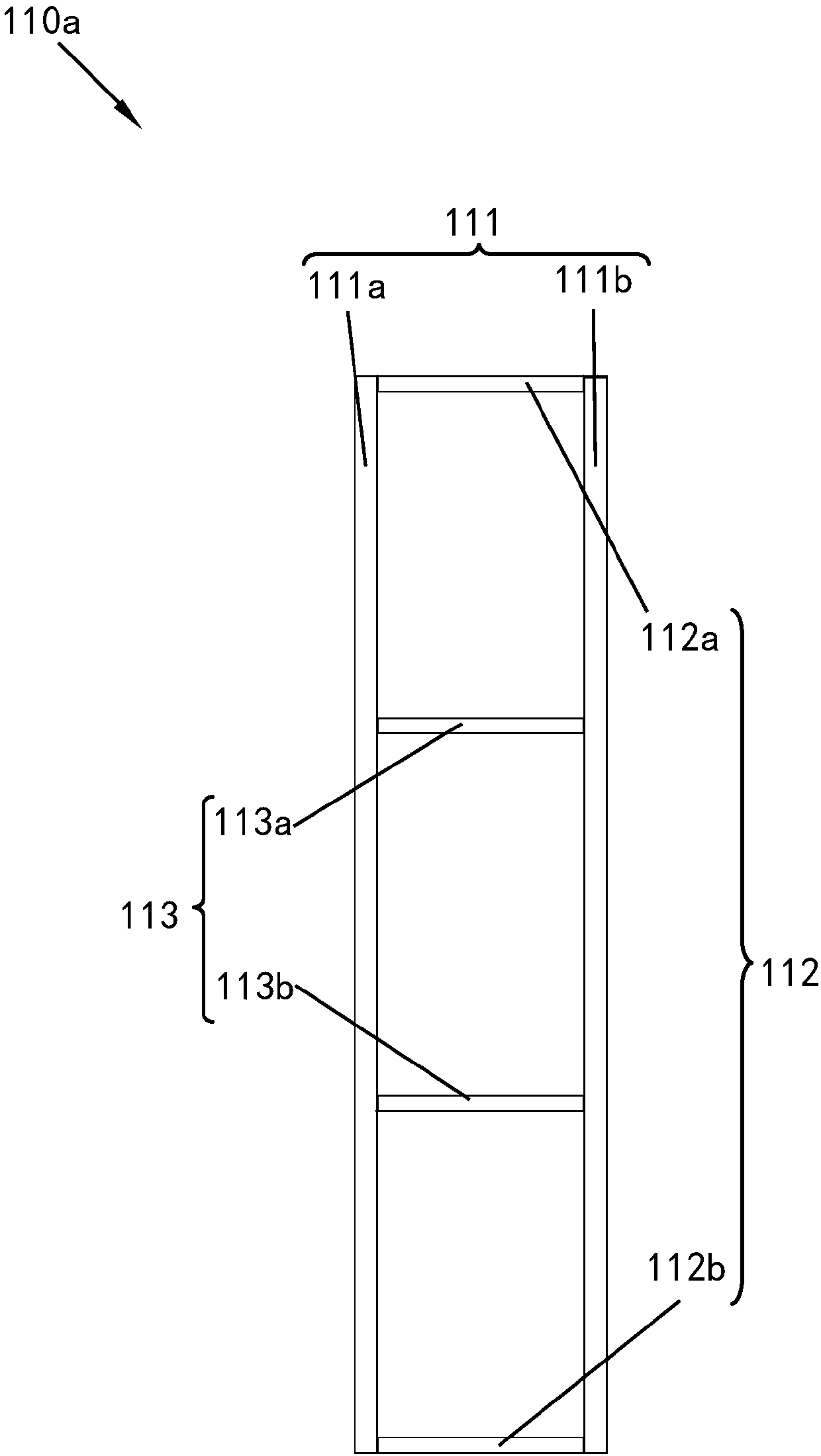

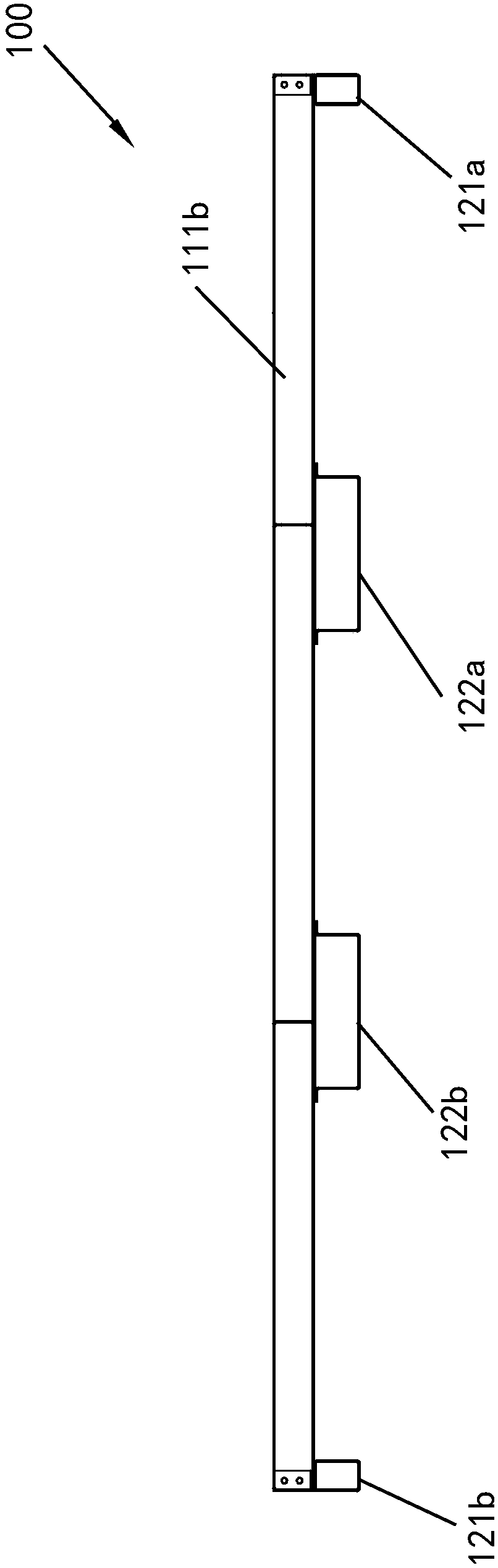

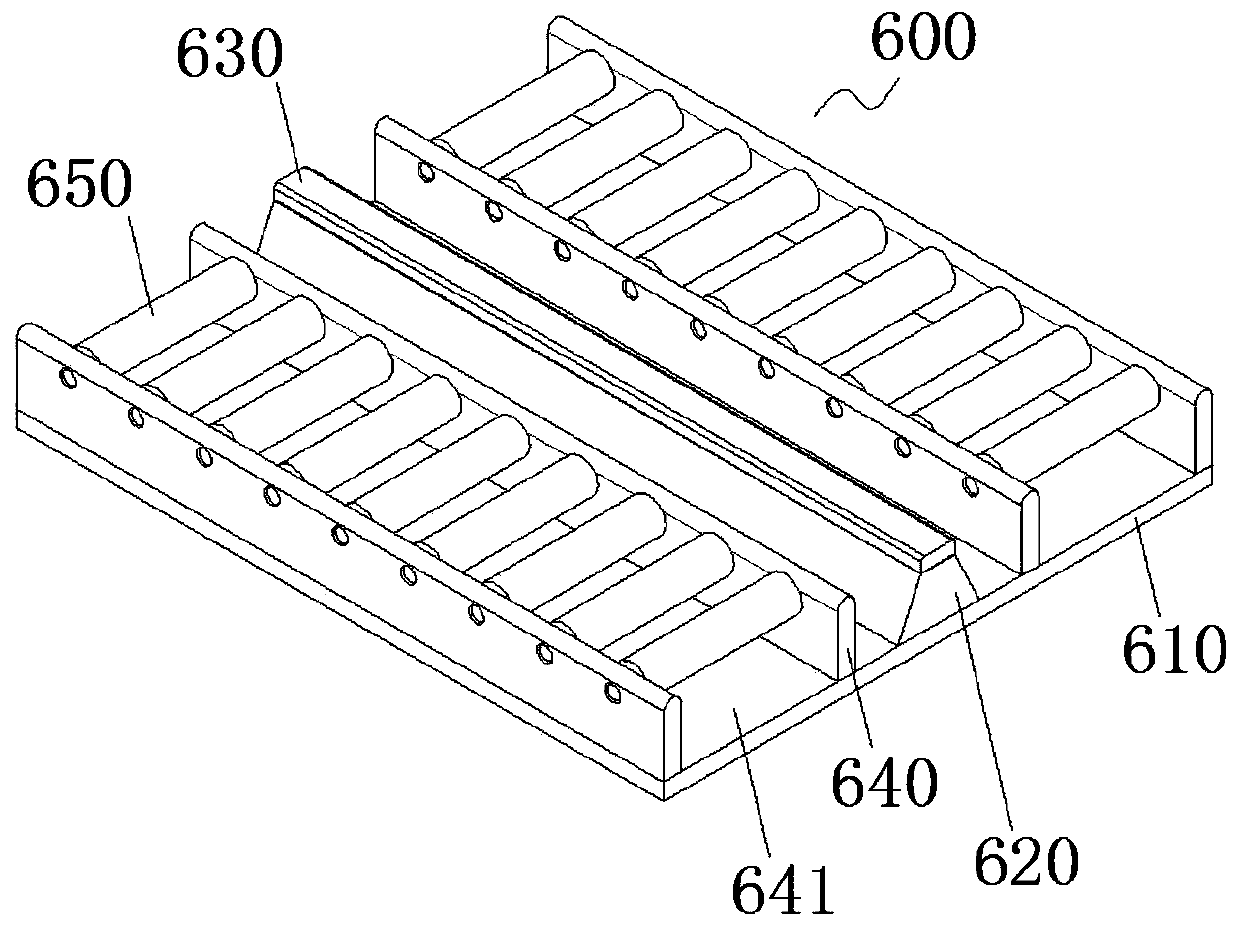

Tray used for container and container having same

The invention discloses a tray used for a container and a container having the same. The tray comprises at least two bracket units, at least two support legs and at least two linking beams. The at least two bracket units are arranged in parallel along a width direction of the tray, each support leg extends below the at least two bracket units along a width direction to support the at least two bracket units, the at least two linking beams are connected to the two bracket units in the width direction, wherein the at least two bracket units, the at least two support legs and the at least two linking beams are detachably connected. The tray according to the invention is easy to disassemble and assemble, easy for backhaul and low in use cost, and the surface of the tray is flat without affecting the flatness of a door plate. Compared with the existing integral wooden tray, the tray according to the invention has the advantages of no need of fumigation, long user period, difficulty on damage and reduced cost.

Owner:上海中集宝伟工业有限公司 +2

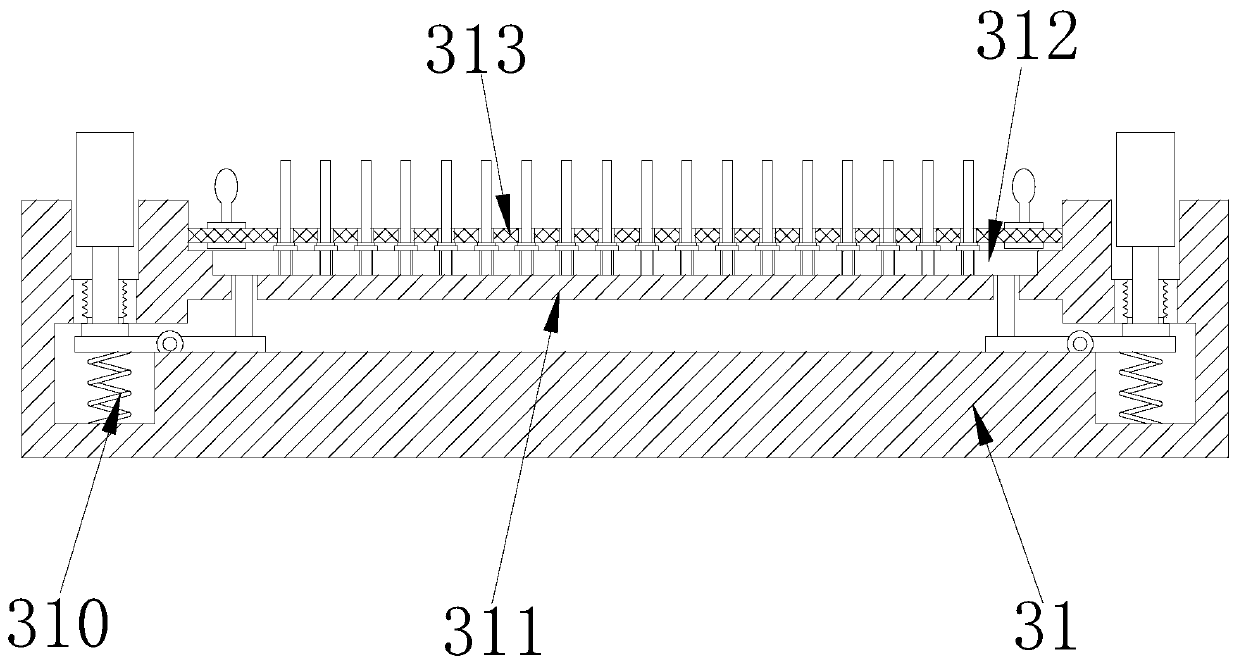

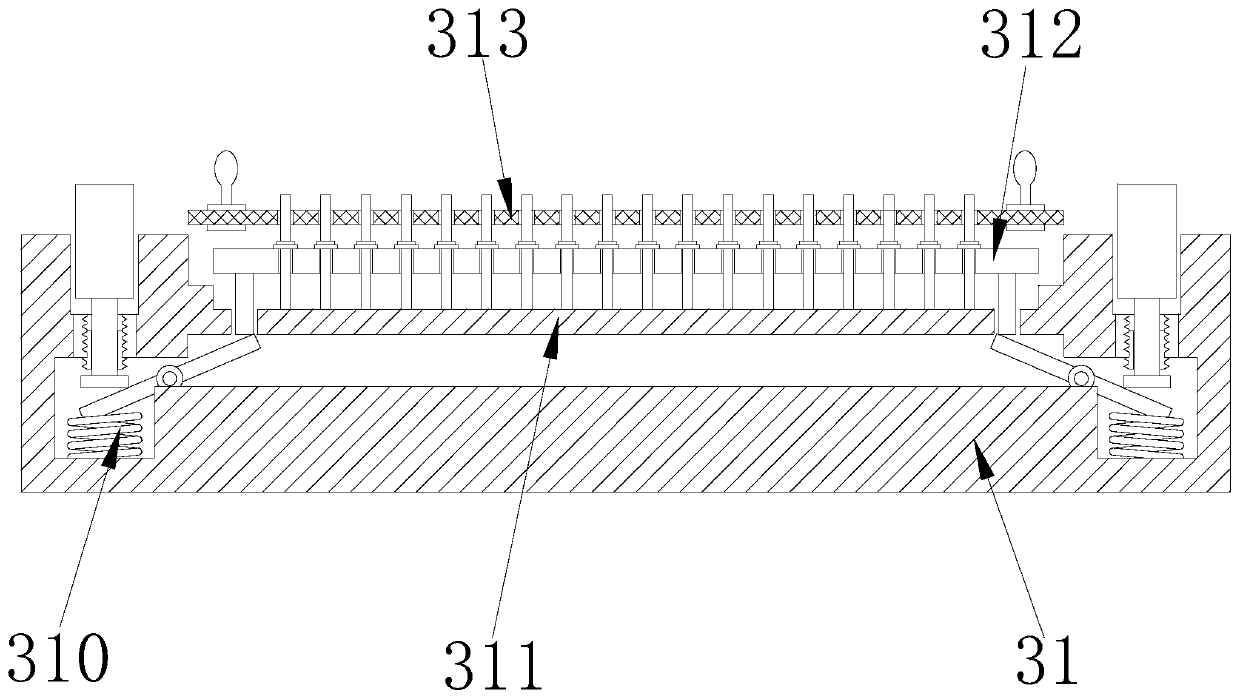

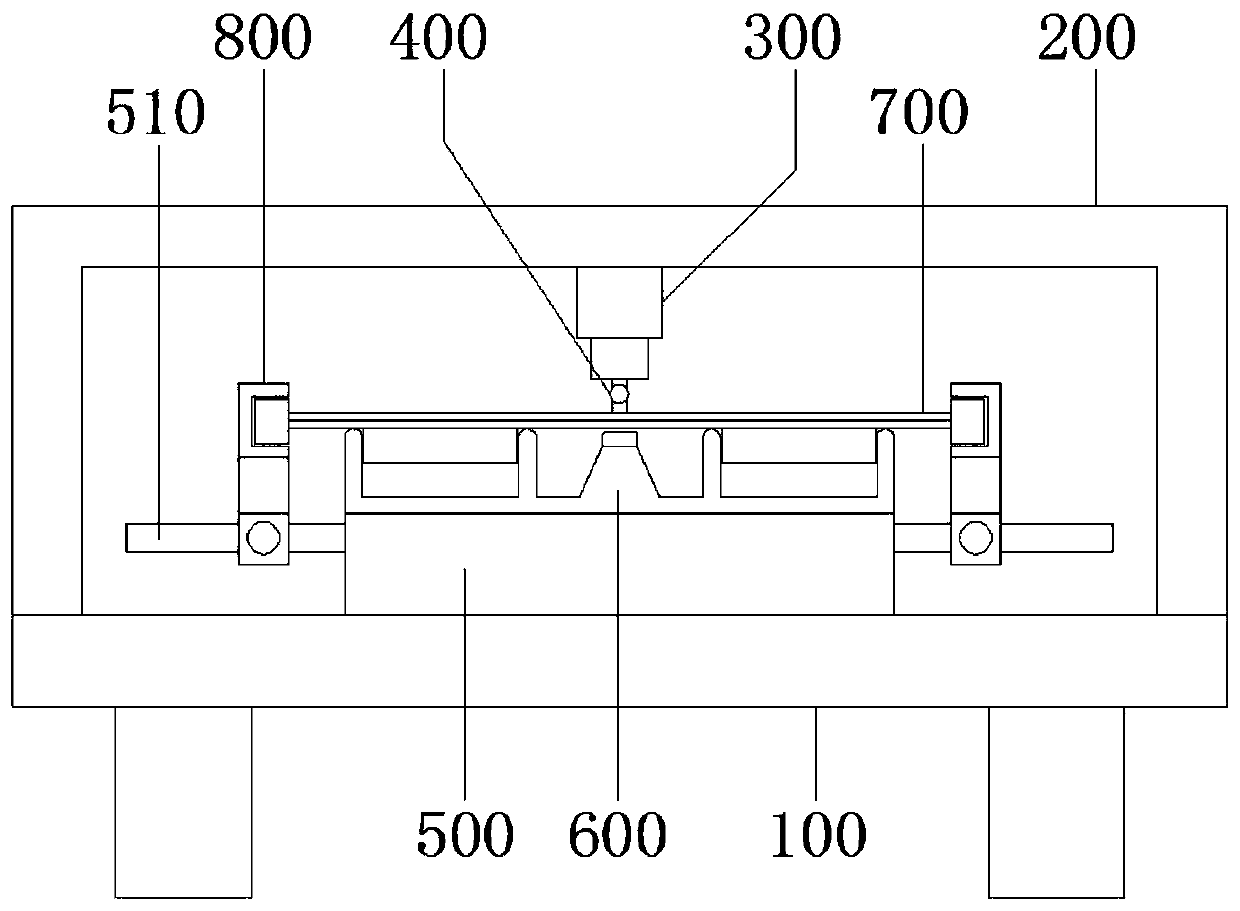

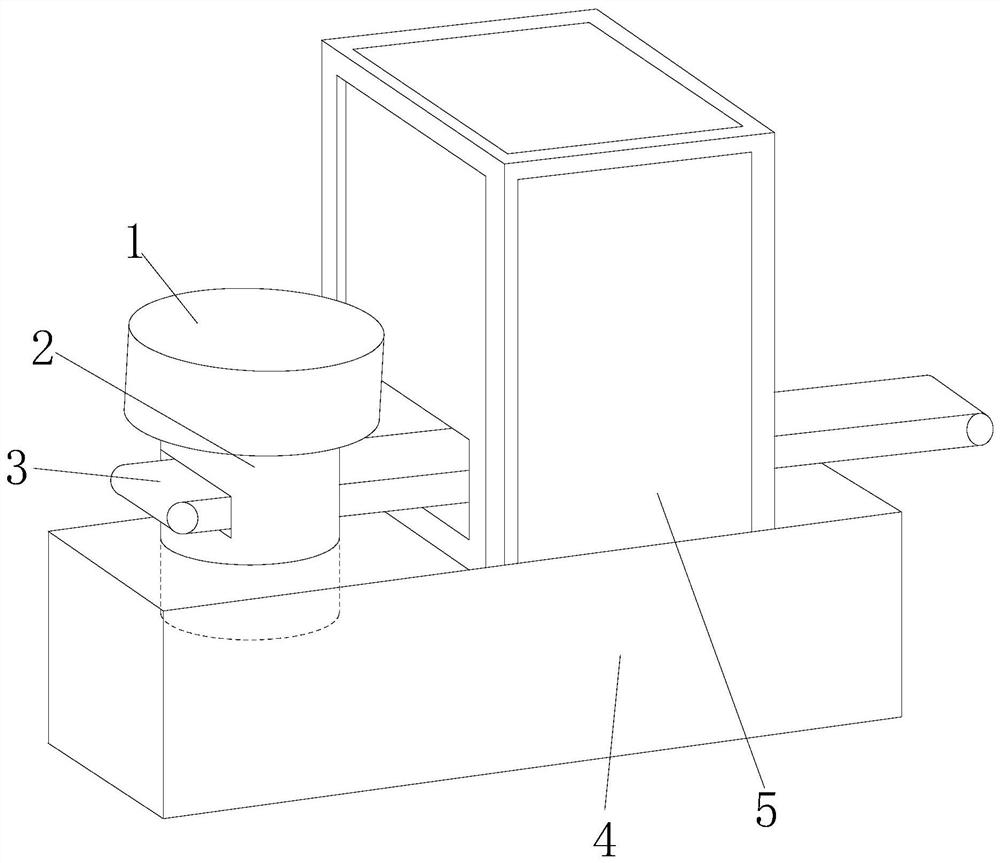

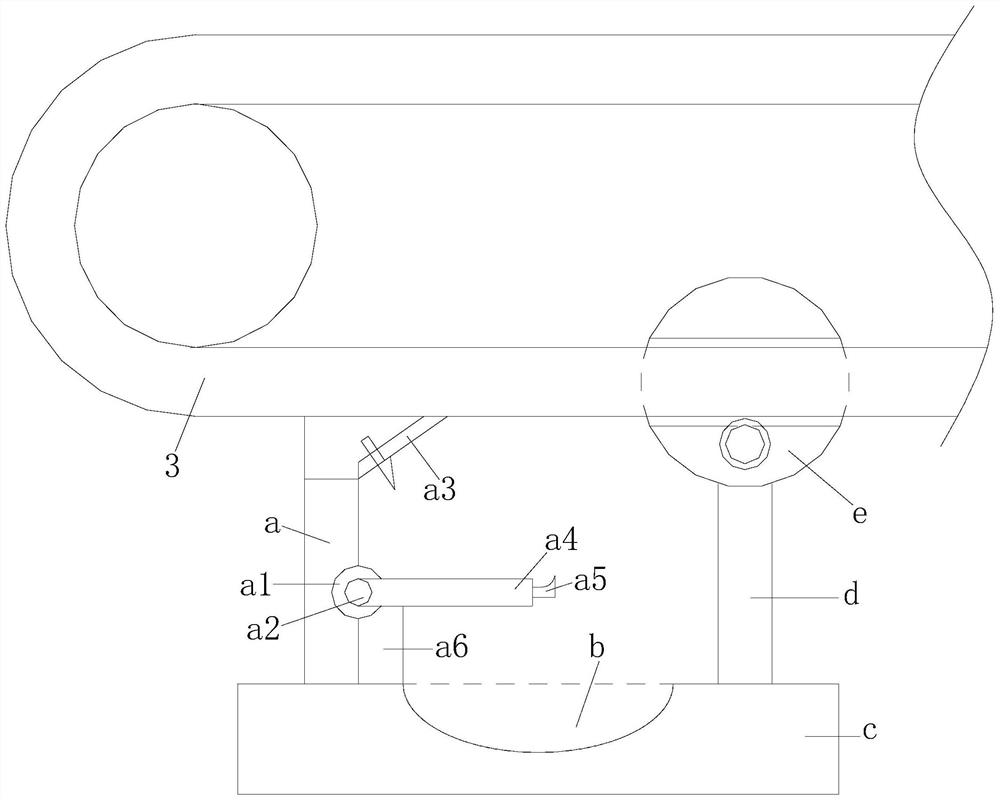

Nailing device for paperboard production

ActiveCN110303560AReduce the impact of precisionEffect of flatnessStapling toolsNailing toolsEngineeringMachine tool

The invention discloses a nailing device for paperboard production and relates to the technical field of paperboard production. The nailing device comprises a machine tool, a rack is erected above themachine tool, bottom legs of the left and right ends of the rack and the top walls of the left and right sides of the machine tool are welded, a lifting device is installed on the bottom wall of themiddle portion of the rack, a nailing mechanism is installed at the bottom end of the lifting device, a working platform is installed at the middle portion of the top wall of the machine tool, a nailing table is mounted on the bottom wall of the working platform, a paperboard is placed above the nailing table, the lifting device and the nailing mechanism are suspended above the paperboard, and theleft and right sides of the paperboard are provided with limiting side frames. According to the nailing device, a waste residue tank can temporarily store plate slag generated in the nailing process,the plate slag directly falls into the waste residue tank, influences of the plate slag on flatness of the table top are avoided, the paperboard can be placed horizontally on the table top of the nailing table, and influences on the precision of paperboard nailing and positioning are reduced.

Owner:邵阳市金美印刷包装有限公司

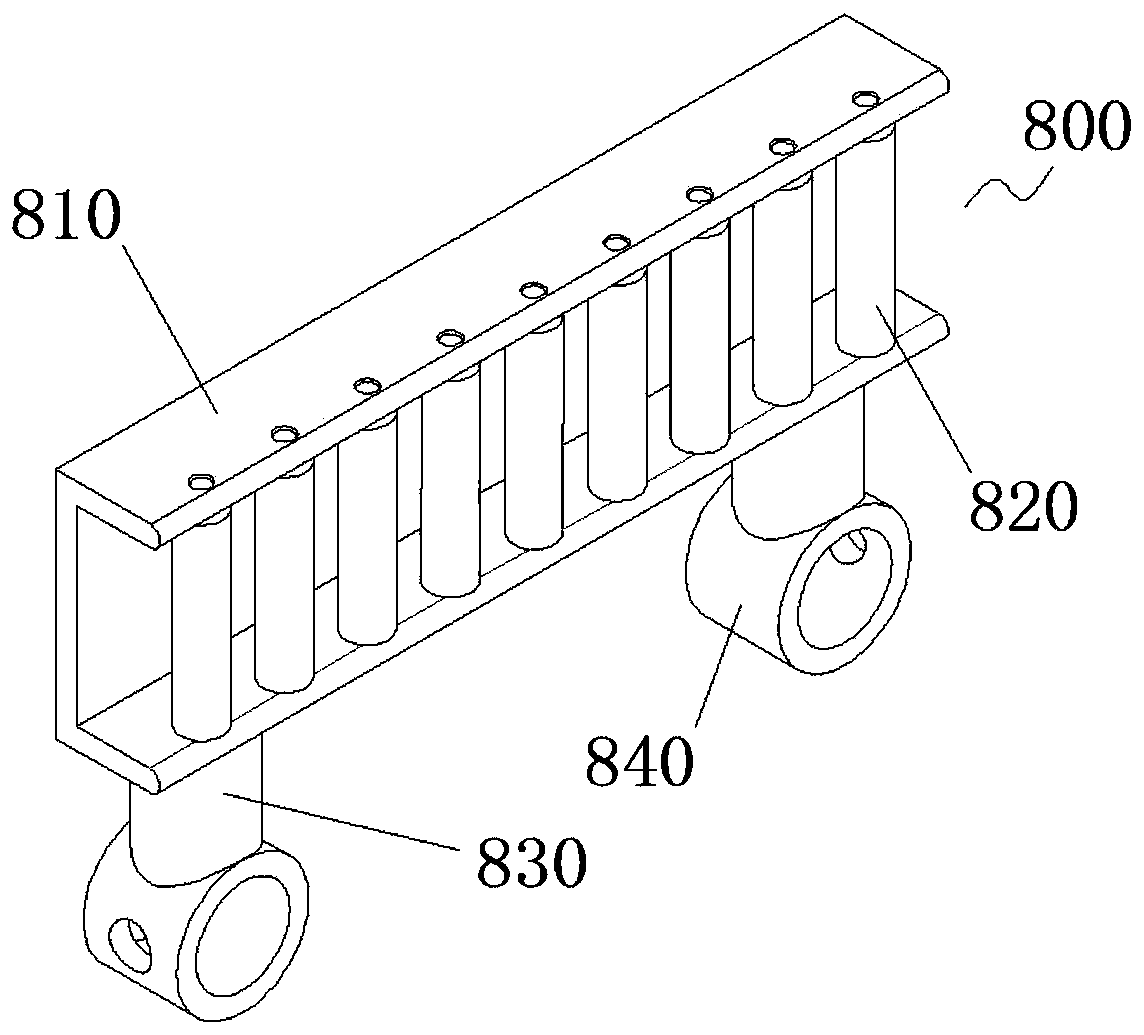

Fused quartz metallurgic roller

The invention provides a fused quartz metallurgic roller, which comprises a ceramic sleeve and a steel shaft passing through the ceramic sleeve. A sand blasting layer is arranged on the outer surface of the ceramic sleeve. In the metallurgic roller, the fused quartz replaces a steel roller or mullite roller and the roller strength is improved; moreover, due to the sand blasting design on the outer surface of the sleeve, articles on the roller is not easy to deviate. The flatness of a meal plate surface is not influenced.

Owner:维苏威赛璐珂陶瓷(苏州)有限公司

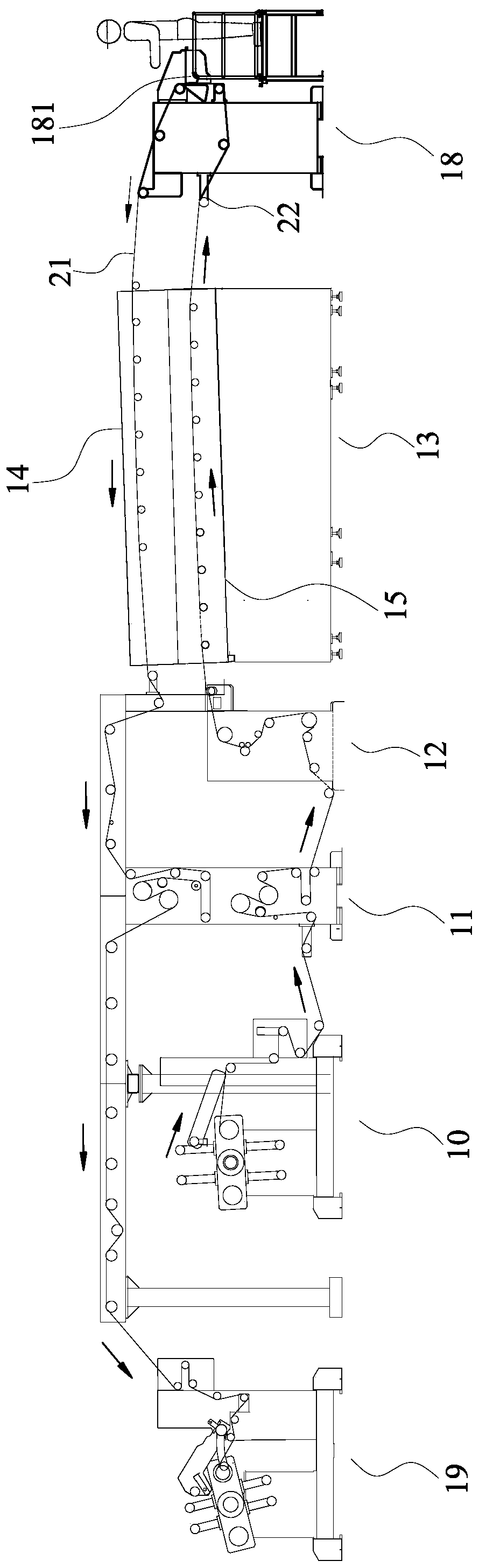

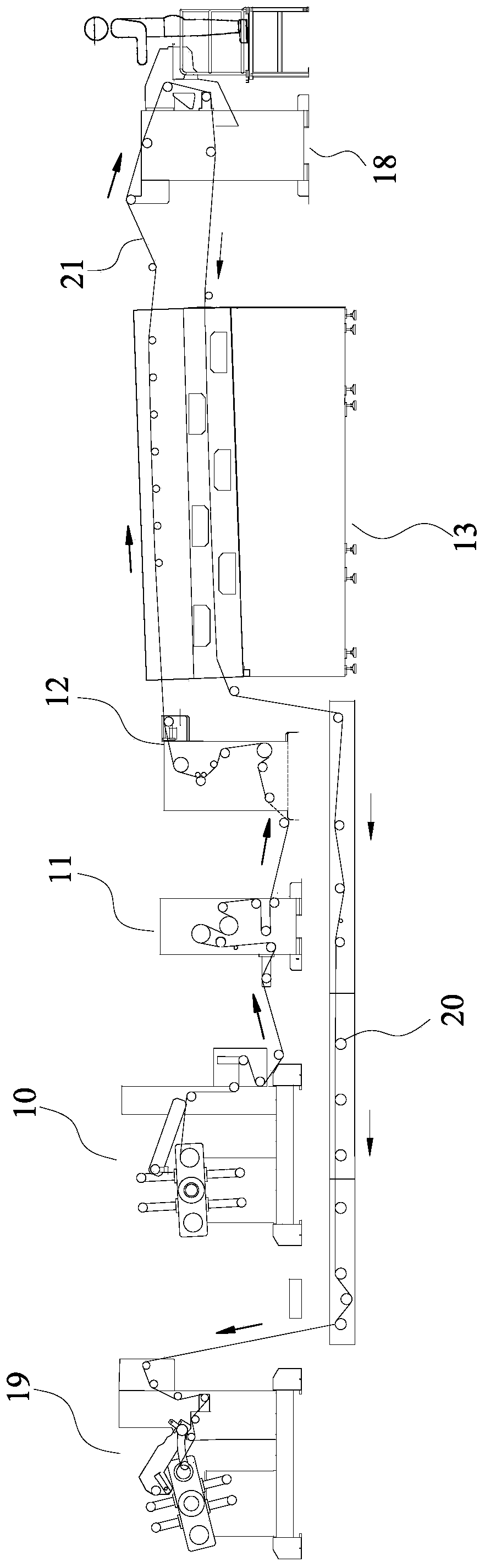

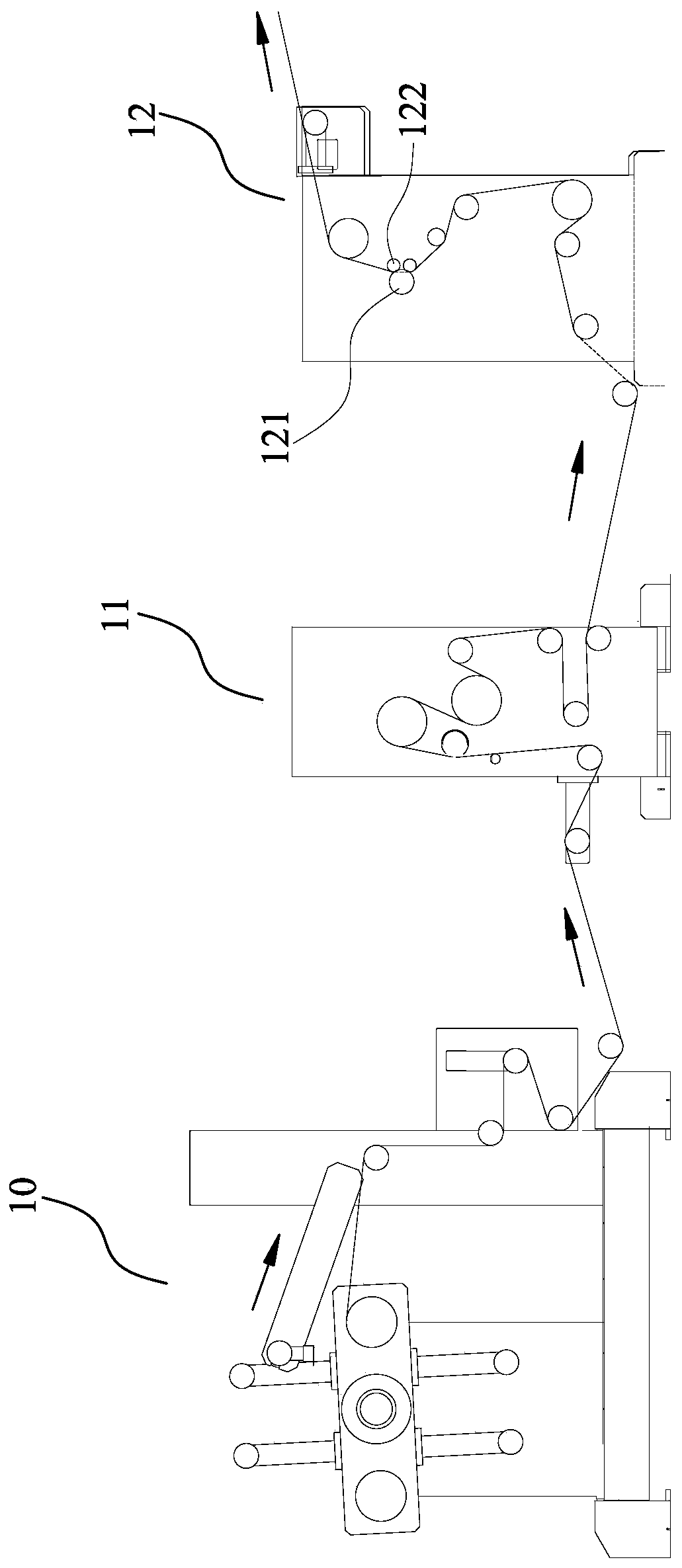

Diaphragm spraying production line

PendingCN111420849AAvoid teardrop blemishesAvoid dripping condensationLiquid surface applicatorsCoatingsStructural engineeringSlurry

The invention provides a diaphragm spraying production line. The diaphragm spraying production line comprises an unwinding mechanism, a coating mechanism, a drying oven and a winding mechanism; the coating mechanism comprises a roller coating mechanism and a spraying mechanism which are used for coating the same side of a diaphragm with slurry, the unwinding mechanism and the winding mechanism arearranged on the same side of the drying oven, the roller coating mechanism and the spraying mechanism are arranged on the two sides of the drying oven correspondingly, and the roller coating mechanism is arranged between the unwinding mechanism and the drying oven; the spraying mechanism comprises a spraying device and spraying guide rollers used for unfolding the diaphragm, the spraying guide rollers comprise the upper guide roller and the lower guide roller, and a material receiving groove used for recycling vaporous slurry is formed below the spraying device; and the diaphragm is unwound from the unwinding mechanism and sequentially passes through the roller coating mechanism, the drying oven, the side, facing the spraying device, of the upper guide roller, the side, facing the spraying device, of the lower guide roller and the drying oven to reach the winding mechanism. According to the diaphragm spraying production line, the vaporific slurry can be prevented from condensing and dropping onto the surface of the diaphragm, the vaporific slurry can be recycled, and the same surface of the diaphragm can be coated without additionally arranging an overturning frame.

Owner:JIANGSU ADVANCED MATERIAL TECH CO LTD

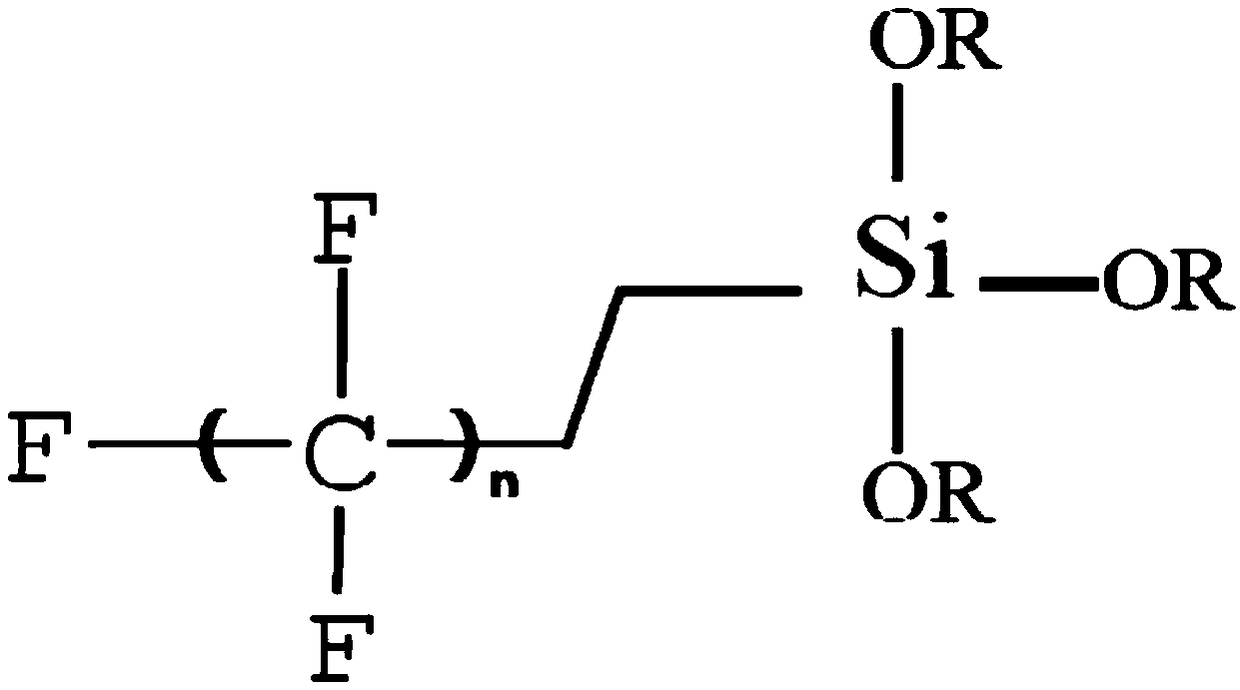

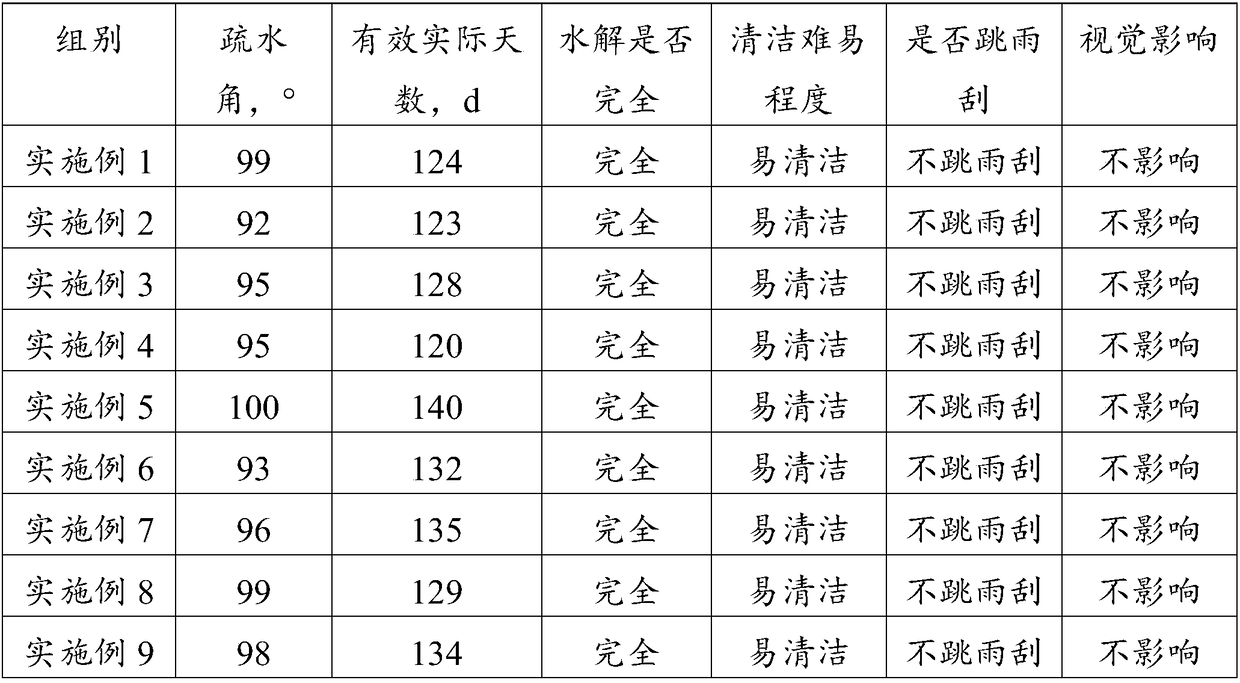

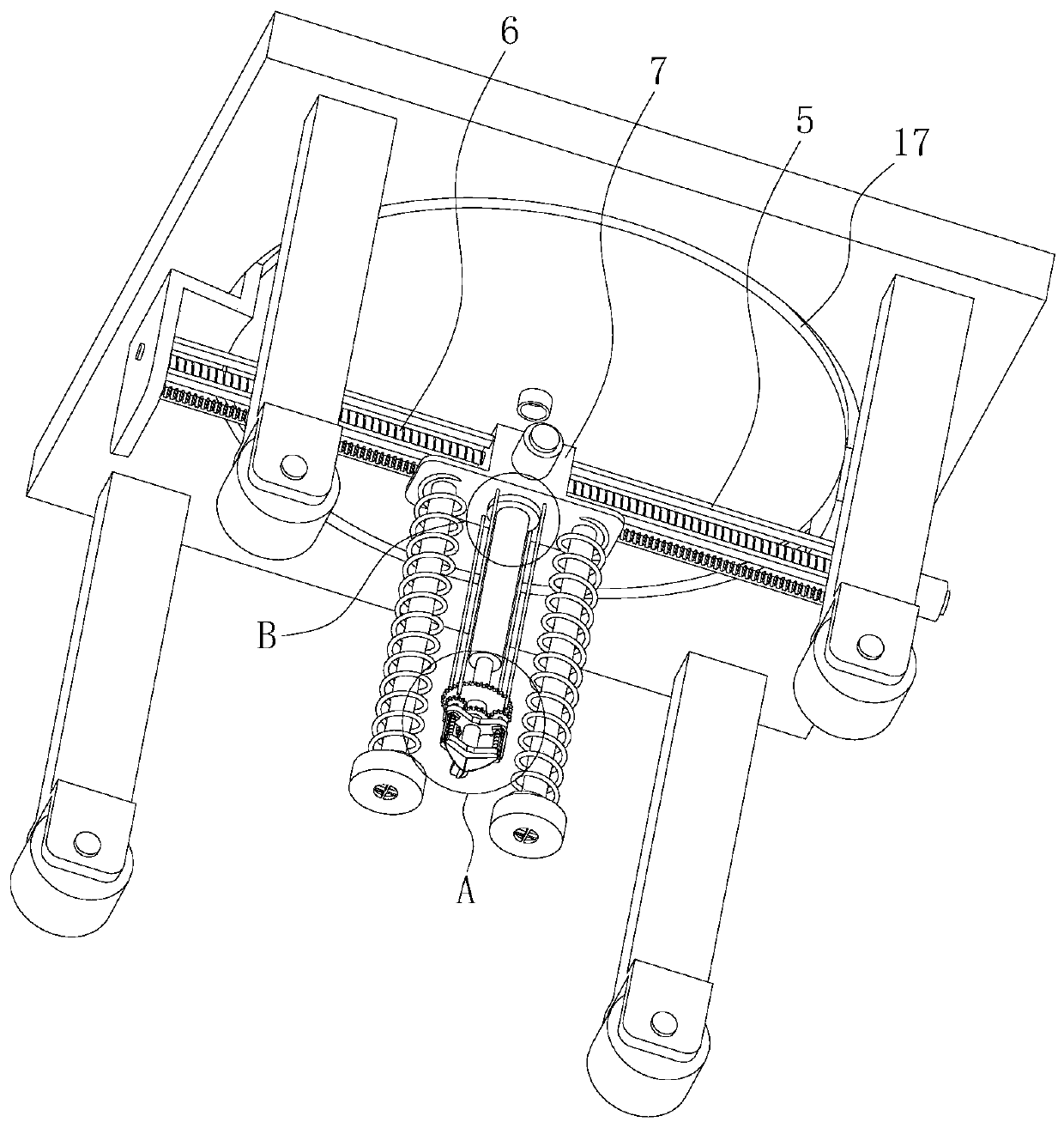

Hydrophobic and oleophobic coating liquid for automobile glass

The invention discloses a hydrophobic and oleophobic coating liquid for automobile glass, and the hydrophobic and oleophobic coating liquid comprises the following components by weight: 0.5-5 parts ofa fluorosilane coupling agent, 5-20 parts of water, 0.5-5 parts of a catalyst, 70-92 parts of a solvent and 0-2 parts of an auxiliary agent. The hydrophobic or oleophobic coating liquid for the automobile glass solves the following problems existing in the prior art: (1) weather resistance of a conventional glass coating agent is poor; (2) self-cleaning ability of the conventional glass coating agent is poor; the conventional glass coating agent is hydrophobic but non-oleophobic; (3) the conventional glass coating agent easily causes jumping of windscreen wipers; and (4) the conventional glass coating agent is high in refractive index.

Owner:广州保赐利化工有限公司

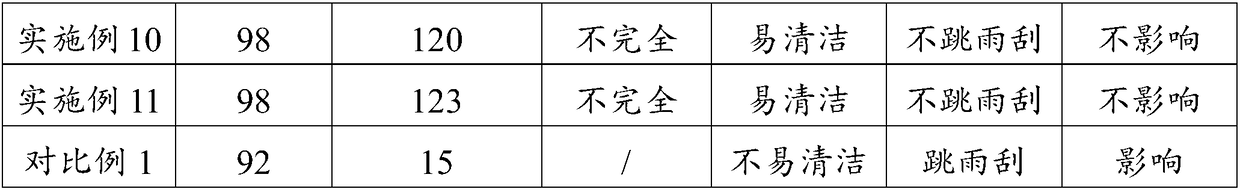

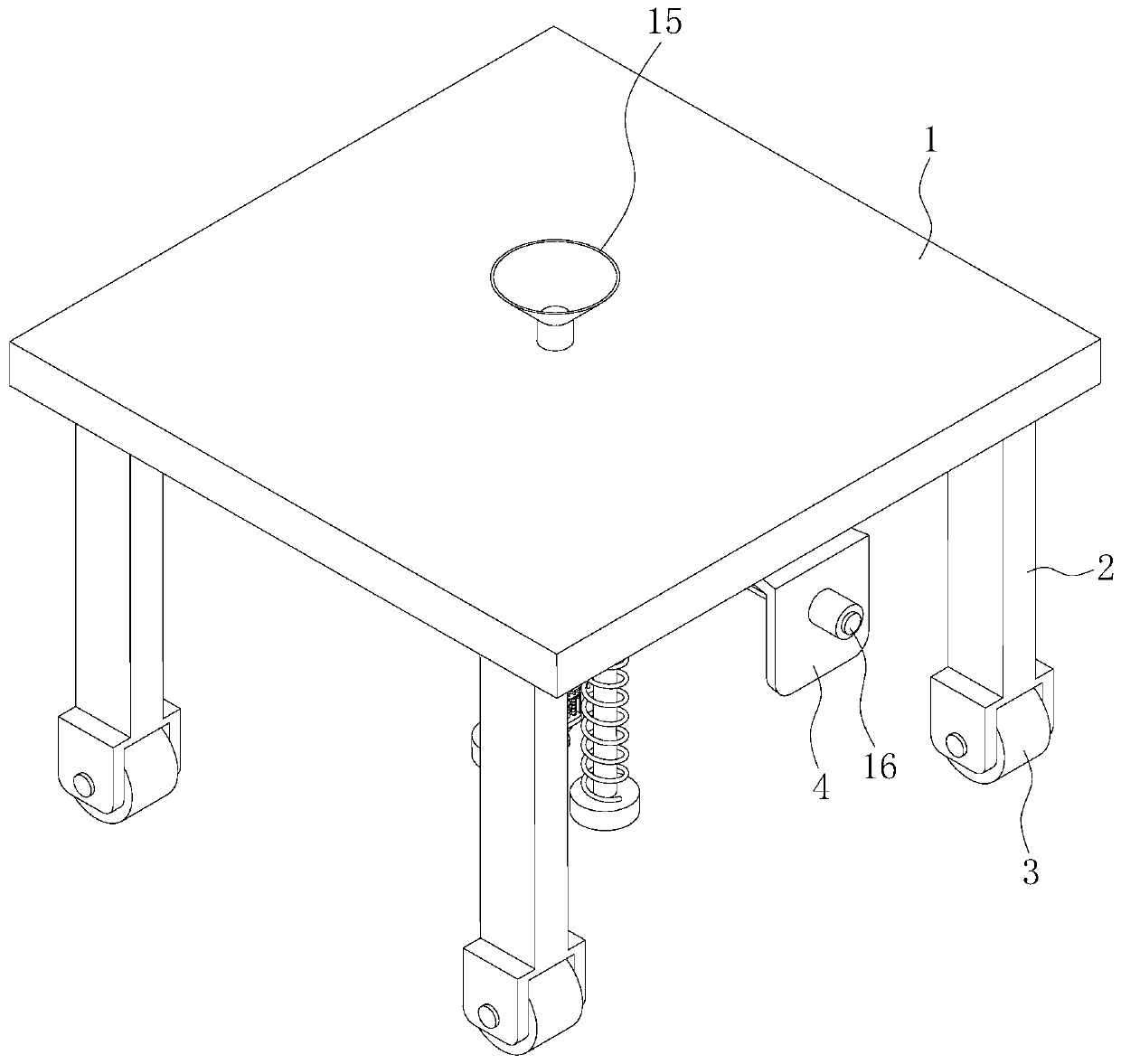

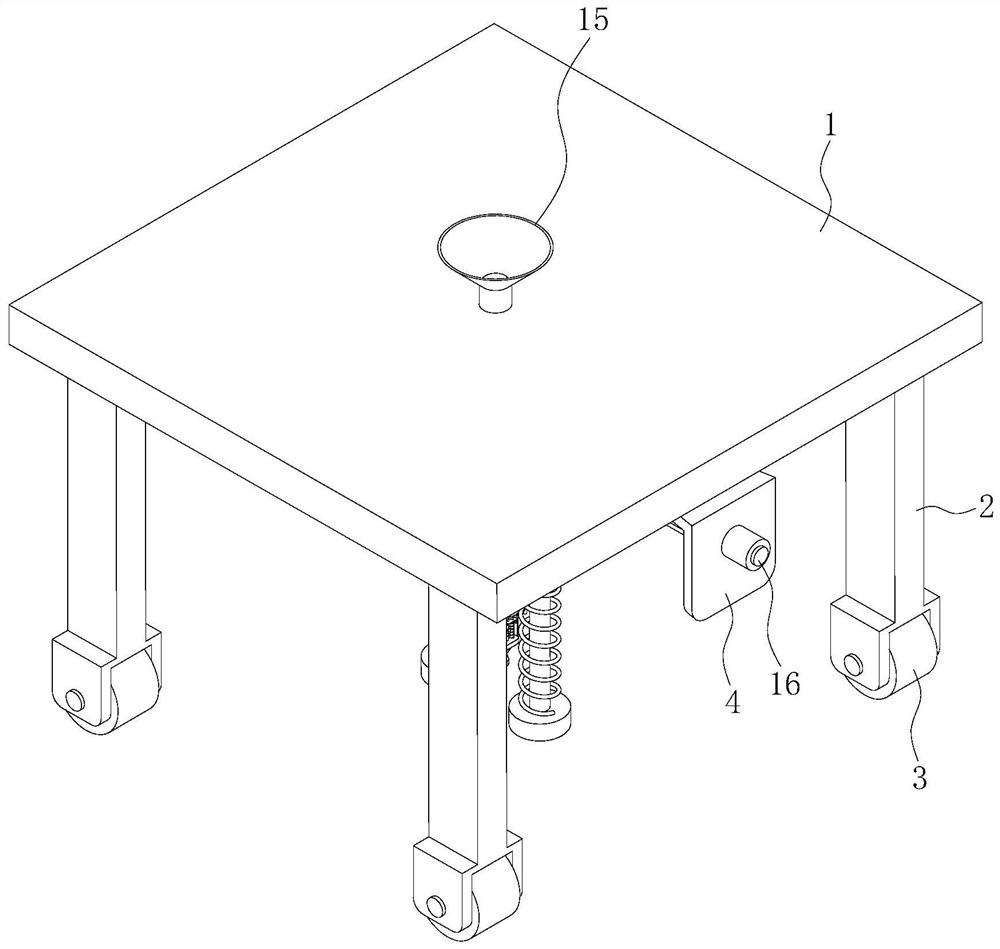

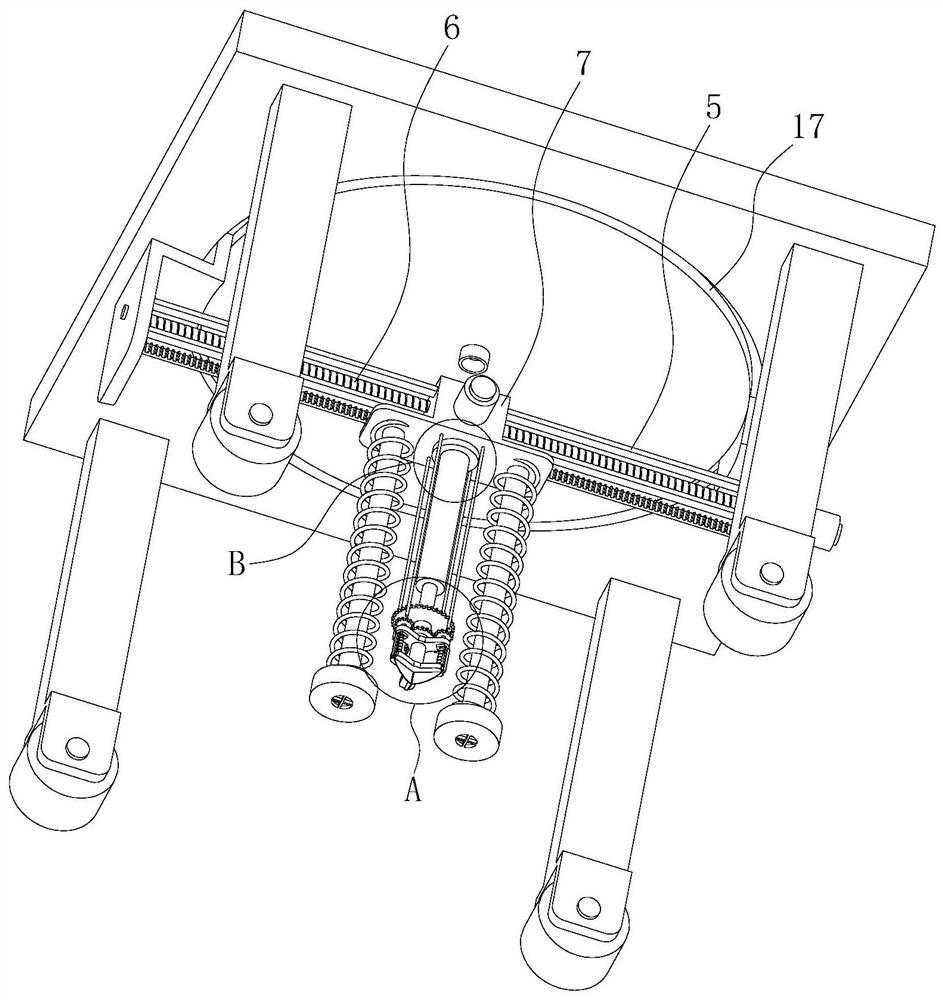

Construction method for surface reinforcement treatment after building foundation pouring

ActiveCN111206632ANo gapsImprove building safetyFoundation repairArchitectural engineeringElectric machinery

The invention belongs to the technical field of building construction, and particularly relates to a construction method for surface reinforcement treatment after building foundation pouring. The construction method for surface reinforcement treatment after building foundation pouring is completed by being matched with a machine for surface reinforcement treatment after building foundation pouring. The method comprises the following steps of 1, construction preparation: preparing concrete, moving the machine to the position over a crack through a roller, and adjusting the position of the machine so that a guide rod can be parallel to the crack; 2, crack drilling: drilling the crack position through a drilling mechanism, and driving the drilling mechanism to move along the crack through a driving motor to enable the crack to become a V-shaped groove; and 3, concrete filling: conveying the concrete into the V-shaped groove through a plastering plate, and plastering the surface of the filled concrete to enable the repaired surface is flush with the foundation. When the machine for surface reinforcement treatment after building foundation pouring is adopted for crack filling, the crackcan be fully filled, it is ensured that no gap exists in the crack, and building safety is improved.

Owner:大庆珑达建工集团有限公司

Concealed surface temperature sensor

PendingCN111122011AAvoid condensationReduce the impactThermometer detailsThermometer applicationsCapillary TubingMechanical engineering

Owner:湖南红橡室内气候技术有限公司

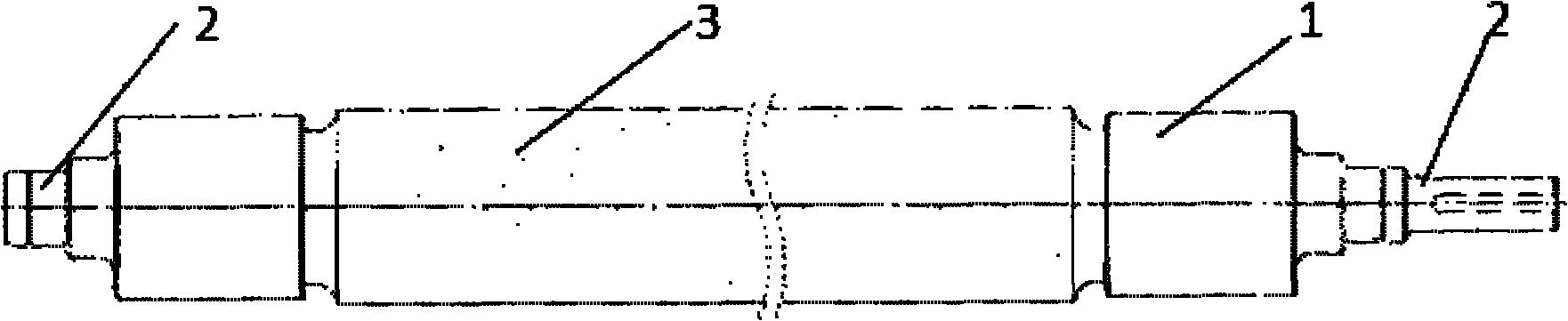

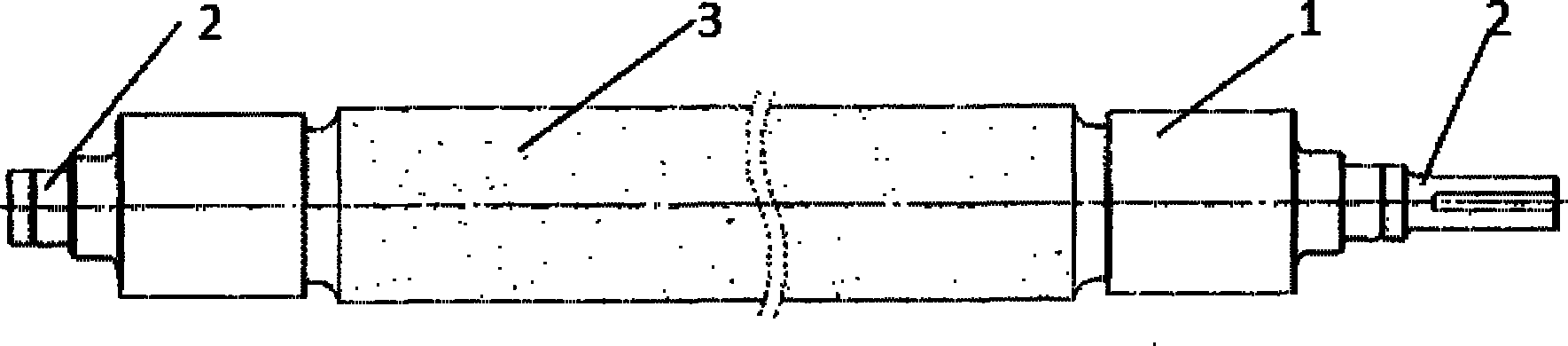

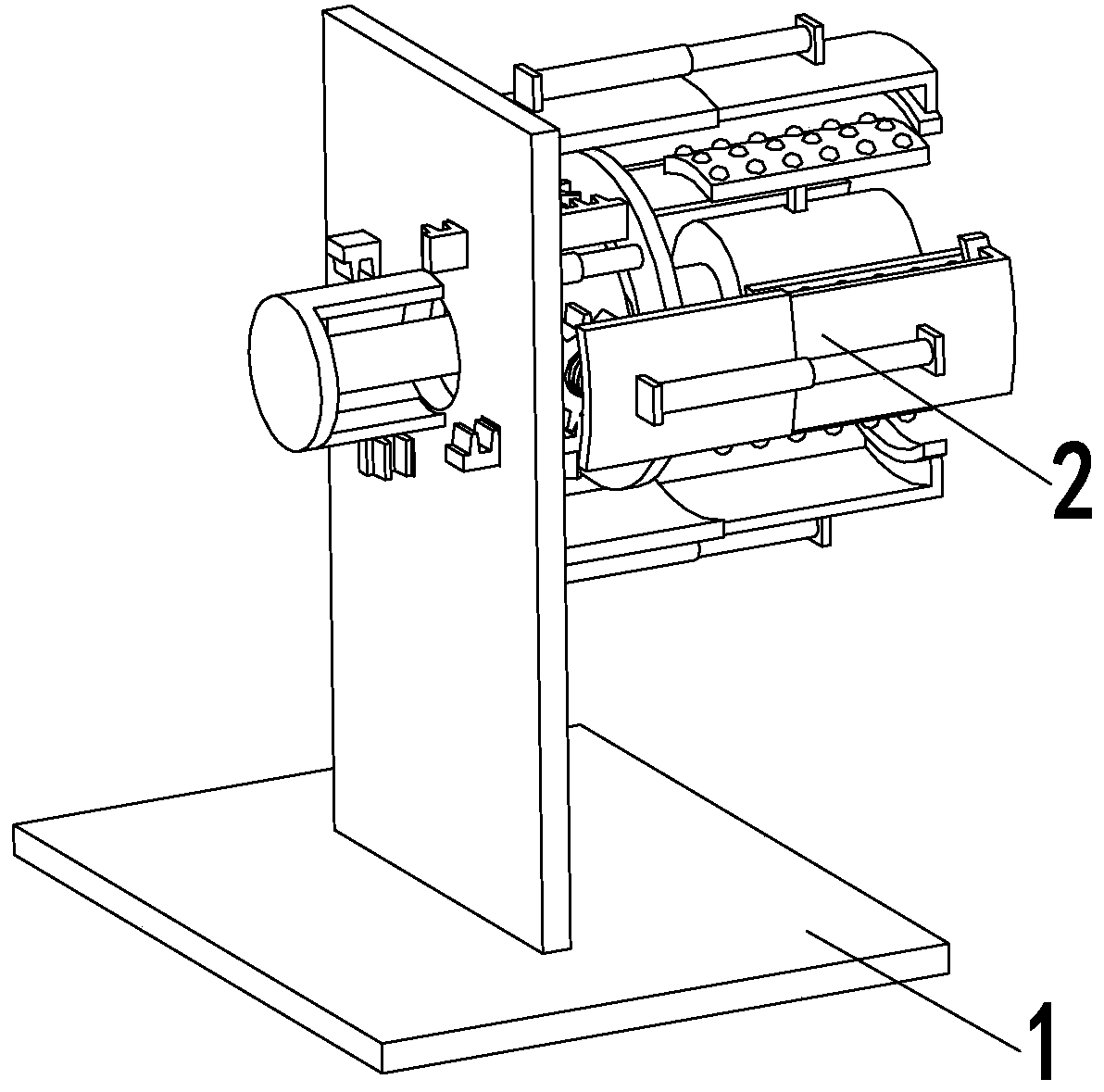

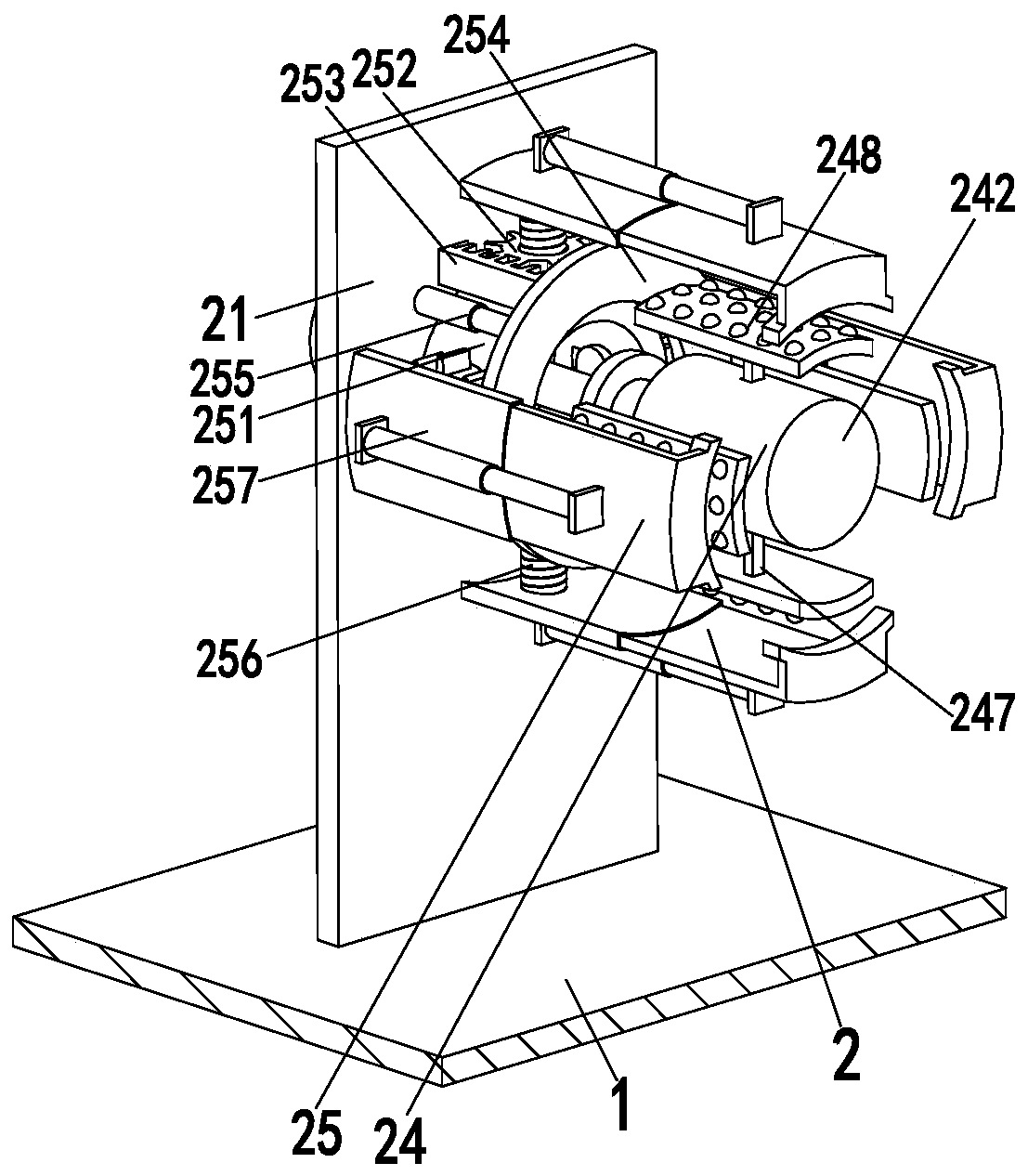

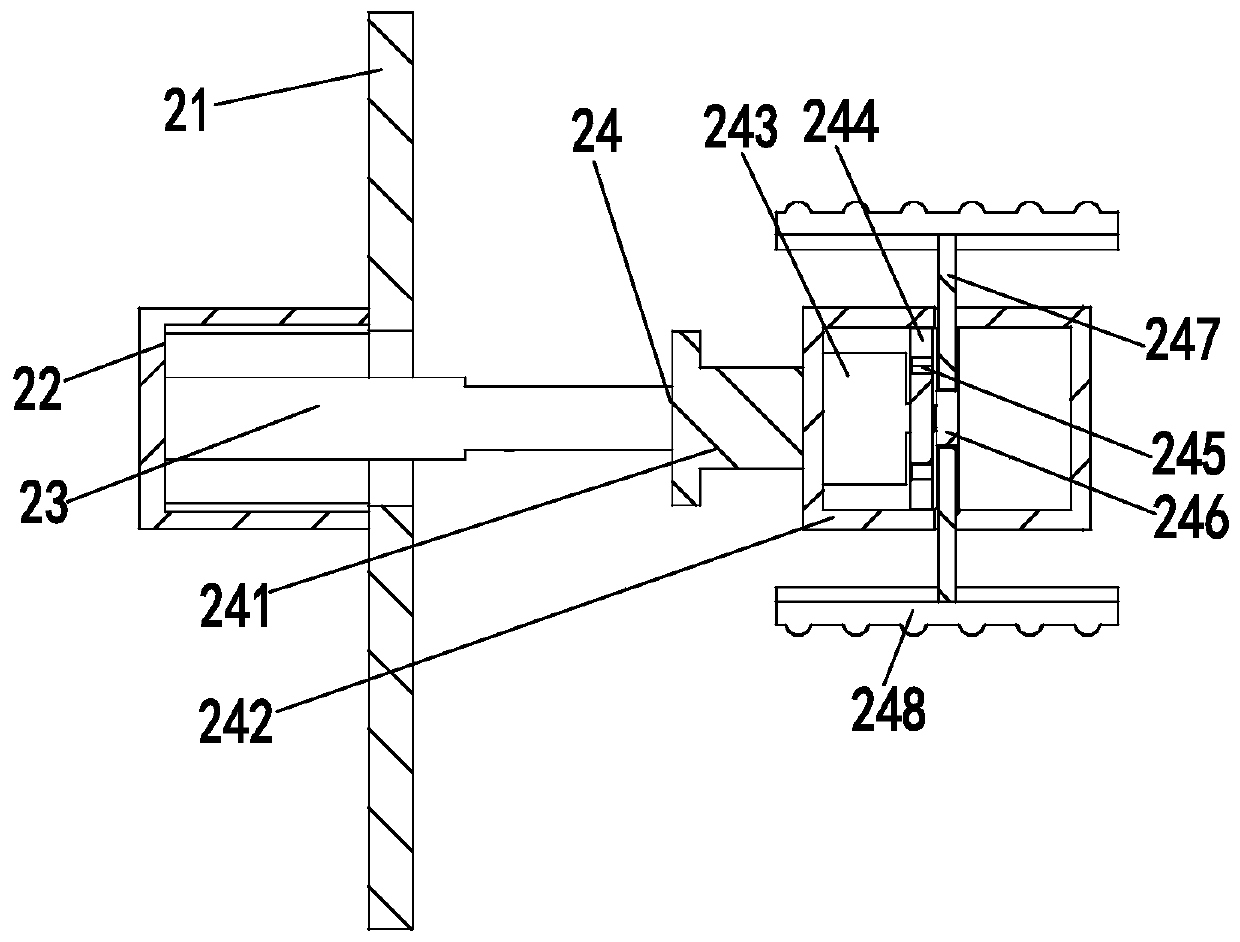

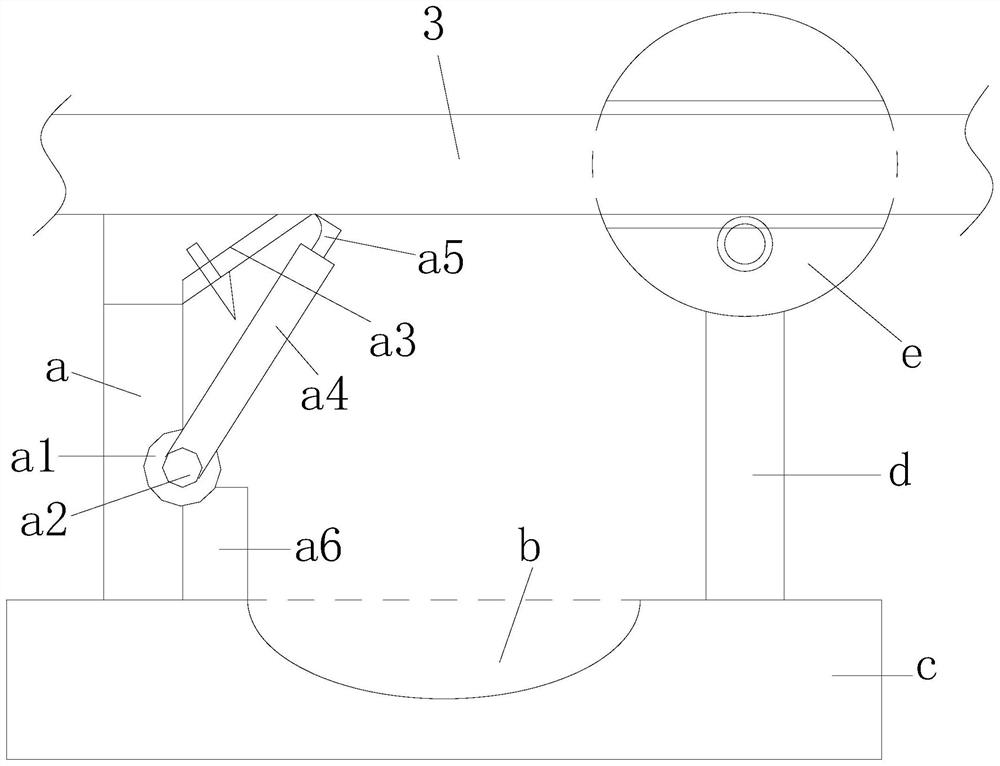

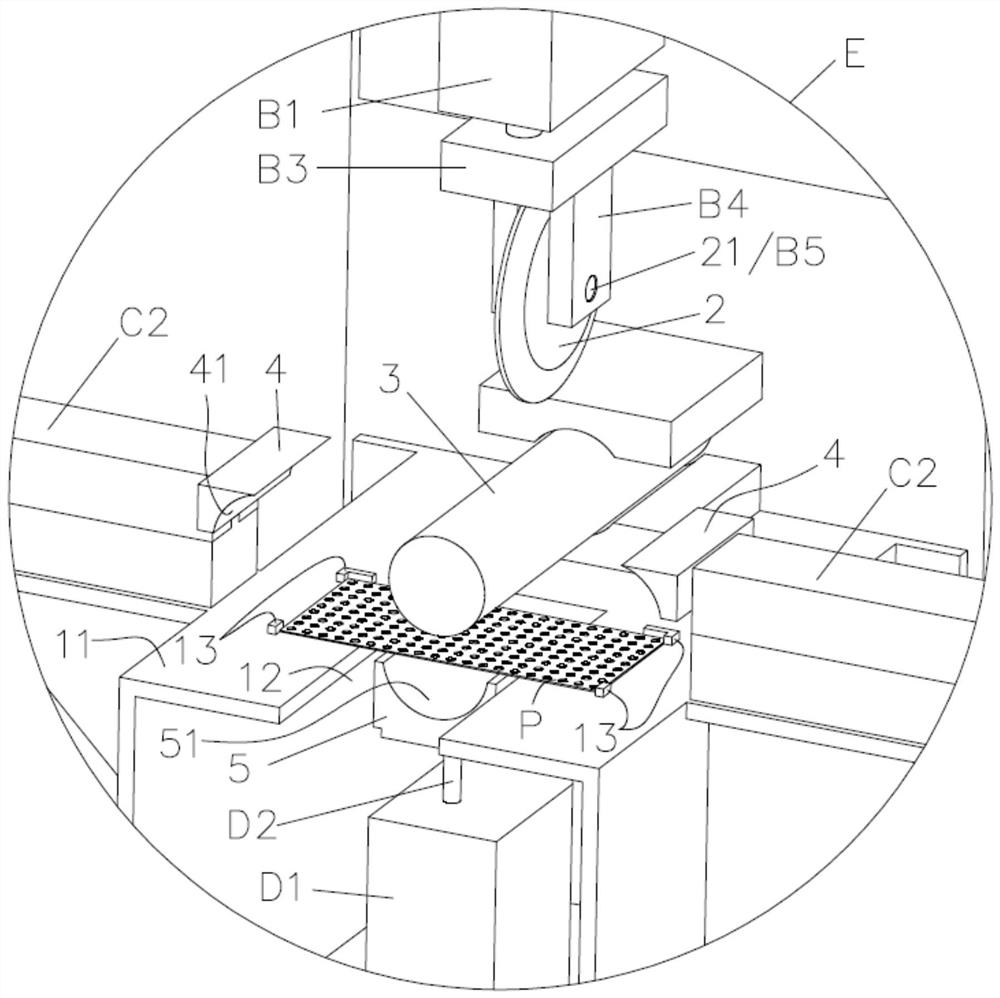

A robot for rubber hose cutting

ActiveCN109079894BNot easy to scratchIncrease labor costMetal working apparatusElectric machineryEngineering

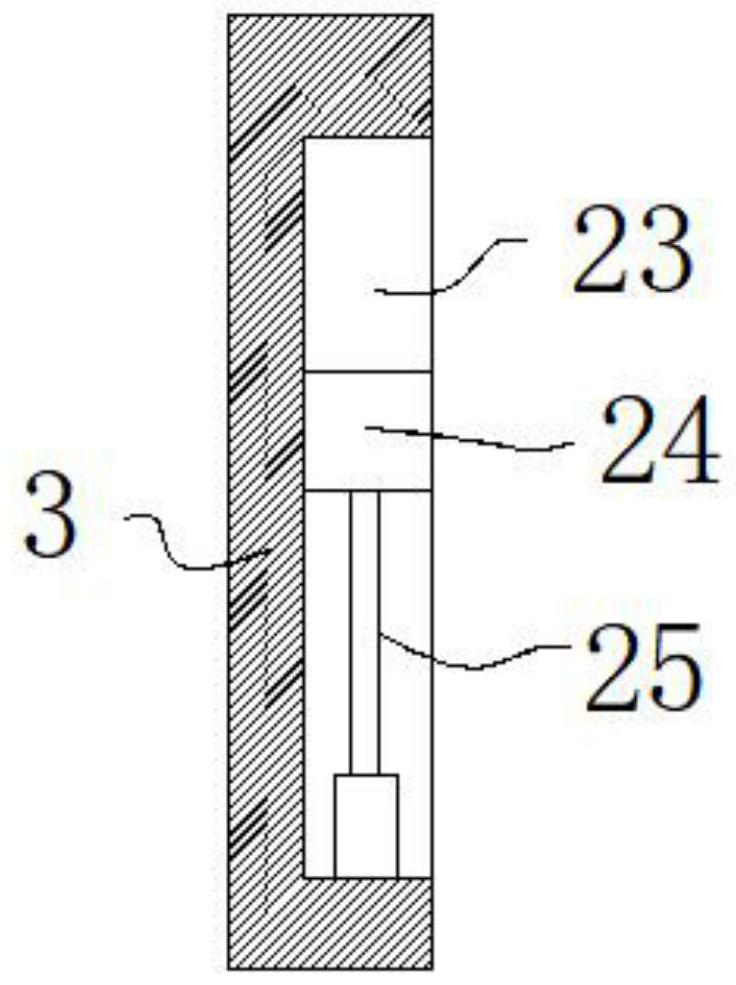

The invention relates to a rubber hose cutting robot. The rubber hose cutting robot comprises a baseplate and a supporting device. The supporting device is mounted on the baseplate and comprises a fixing plate, a fixing frame, a moving air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the inner wall supporting mechanism comprises a connecting frame, a workingcylinder, an adjusting motor, an adjusting circular plate, a circular pin, a fixed circular plate, an adjusting rod and a supporting plate; the outer wall supporting mechanism comprises an adjustingcolumn, an adjusting cylinder, an adjusting rack, a connecting ring, an adjusting electric push rod, an adjustment screw rod and a supporting frame. The rubber hose cutting robot can solve the problems that in an existing process of cutting rubber hoses, the labor cost is high, the work efficiency is low, cut surfaces are unsmooth, and the surfaces of the rubber hoses are easily scratched; the function of carrying out automatic assisting in the process of cutting the rubber hoses can be achieved; the rubber hose cutting robot has the advantages that the labor cost is low, the work efficiency is high, the cut surfaces are smooth, the application range is wide, and the surfaces of the rubber hoses are unlikely to scratch.

Owner:青岛橡六胶管有限公司

A method for preparing a mask with high aperture ratio and the mask

ActiveCN104505471BIncrease opening ratioReduce widthSolid-state devicesSemiconductor/solid-state device manufacturingPhoto irradiationUltraviolet lights

The invention provides a method for preparing a mask with a high aperture ratio, comprising the following steps: S1, coating a photocurable material on the surface of the mask, and performing ultraviolet light on the photocurable material in the main body area of the mask and the connecting bridge reserved area. Light irradiation and curing to form a low polymer, cleaning and removing the uncured light-cured material on the surface of the connecting bridge to be corroded, and then immersing the mask plate coated with a low polymer in a corrosive solution to remove the connecting bridge to be corroded Zone, to obtain a mask plate coated with low polymer on the surface; S2: remove the low polymer on the surface of the mask plate to obtain a mask plate with a high aperture ratio. The present invention can effectively increase the aperture ratio of the mask plate by reducing the width of the connecting bridge of the main body of the mask plate, specifically, the aperture ratio can be increased by 30-50%.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

A display module bonding assembly line

ActiveCN111055577BClean thoroughlyEffect of flatnessLamination ancillary operationsLaminationRubber materialEngineering

The invention discloses an assembly line for bonding display screen modules. The structure includes a fixed block, a cutting device, a conveyor belt, a fixed base, and an assembly cavity. In cooperation, the cutting device is installed in the fixed block. The beneficial effect of the present invention is that the reverse movement of the roller and the conveyor belt is controlled by external mechanical force, so that the brush and the soft rod rub against the surface of the conveyor belt, and the impurities on the surface are cleaned. And because the brush and the soft rod are both tough materials, the brush and the soft rod will return to their original shape after they are separated from the surface of the conveyor belt. The combination of the fixed scraper and the movable scraper is used to remove the dried rubber from both sides to the middle, and the dropped rubber enters the slag collection tank to ensure that the flatness of the conveyor belt surface is not affected by impurities.

Owner:上海芯辉电子股份有限公司

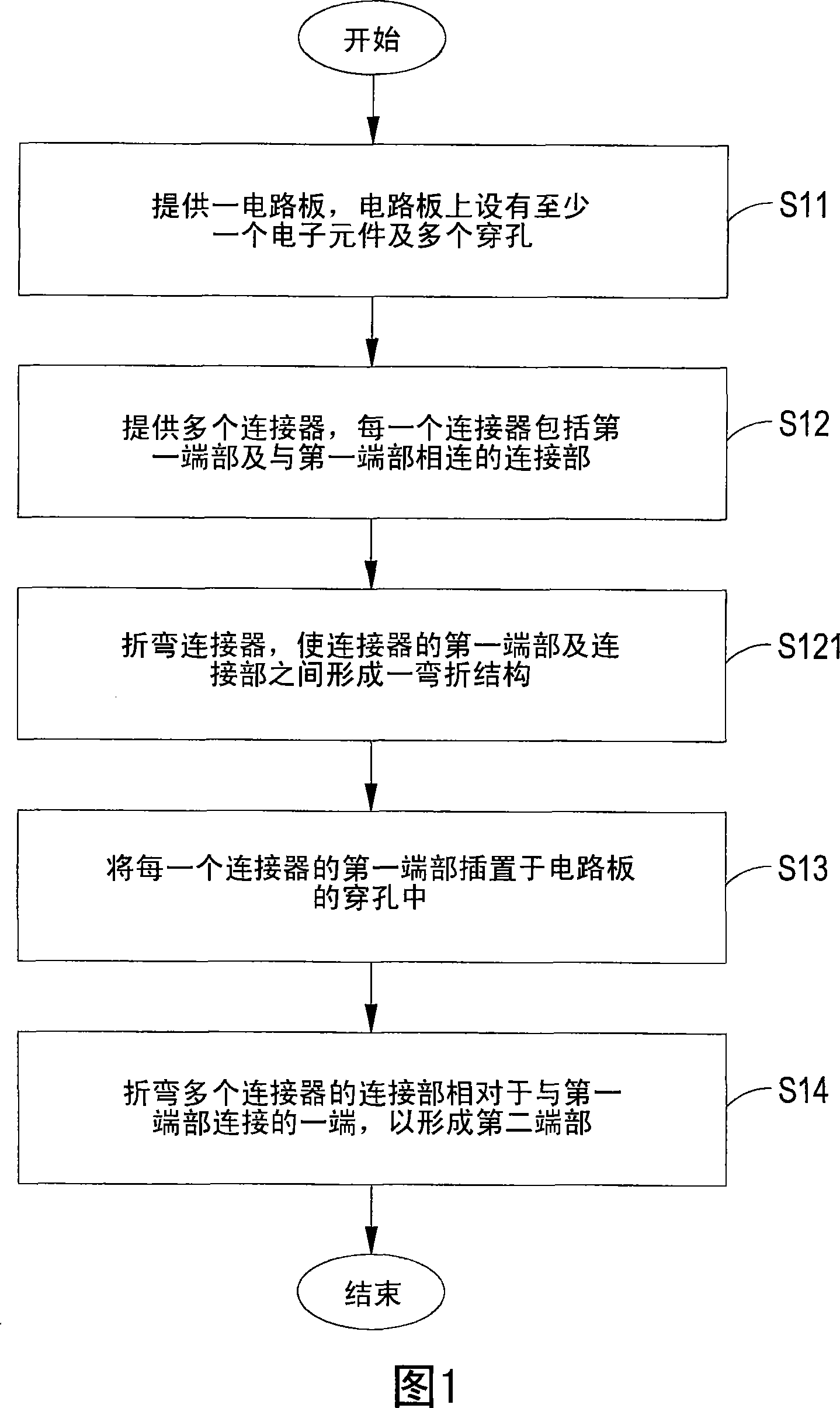

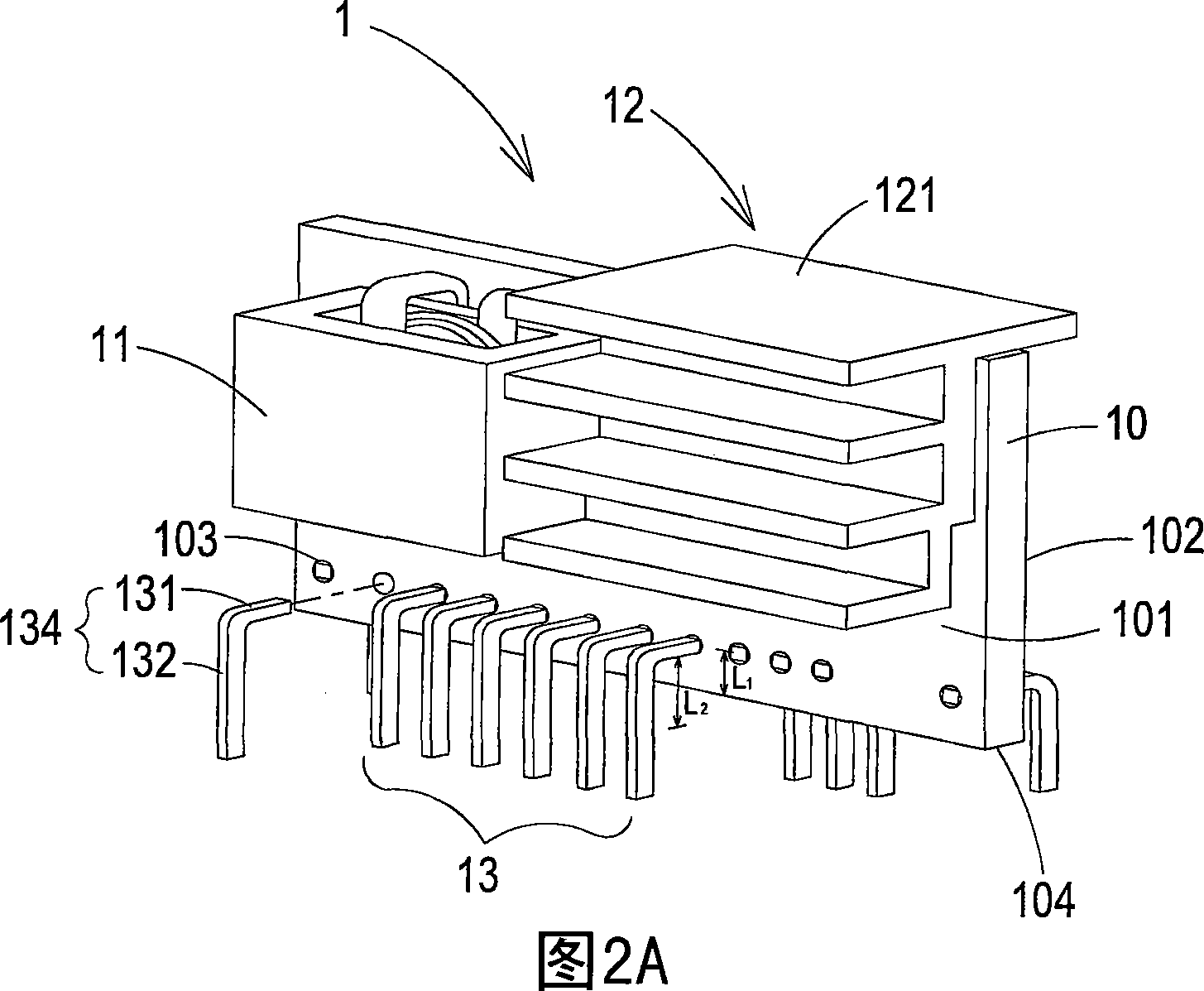

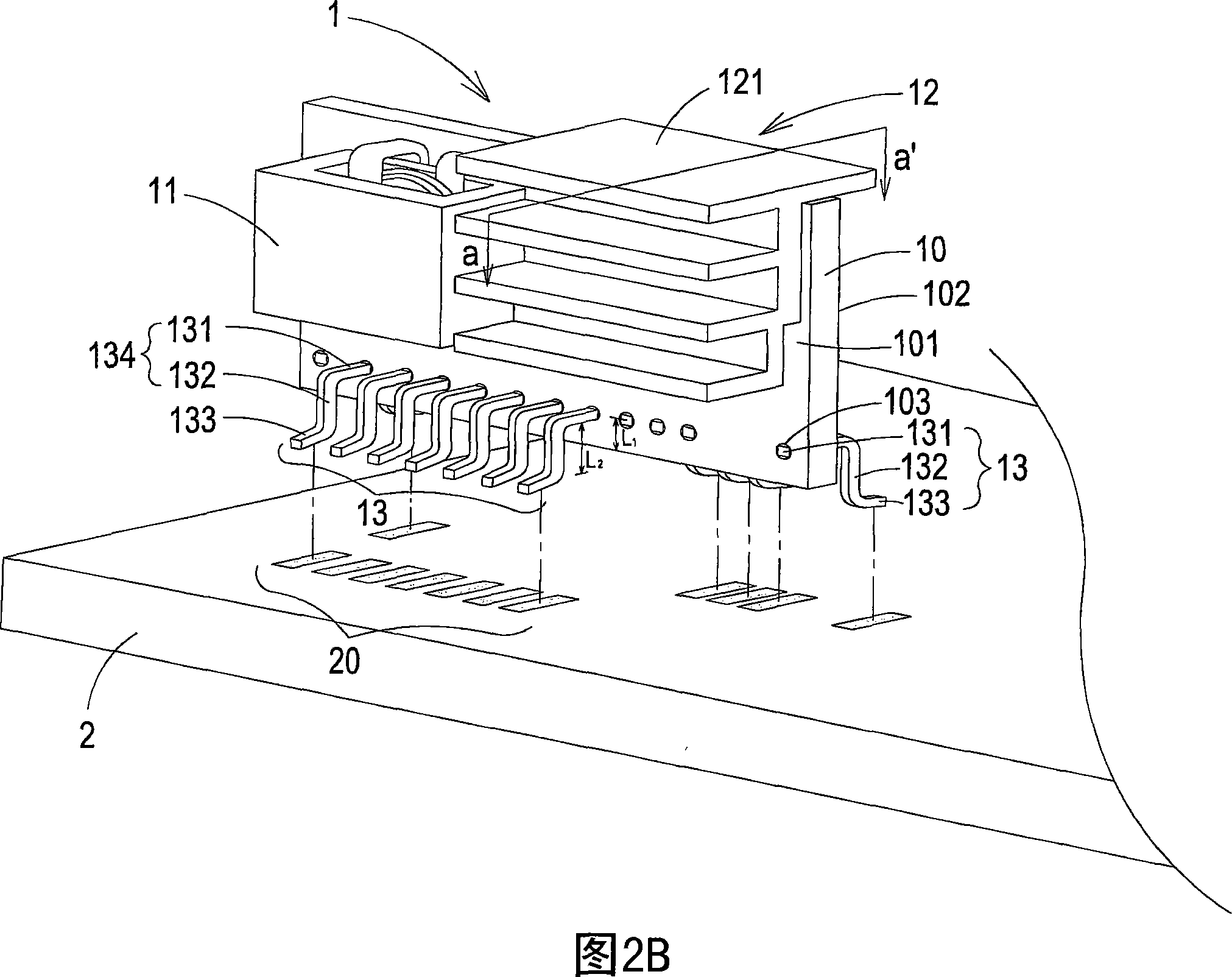

Surface-mount circuit board piece module and preparation method thereof

InactiveCN101534604BGuaranteed flatnessEffect of flatnessPrinted circuit assemblingPrinted circuit non-printed electric components associationSurface mountingElectrical and Electronics engineering

The invention relates to a surface-mount circuit board piece module and a preparation method thereof, wherein the surface-mount circuit board piece module mainly comprises a circuit board, on which at least one electronic element is arranged, and a plurality of connectors; each connector comprises a first end part which is at least partially embedded in the circuit board, a connection part connected with the first end part, and a second end part formed by extending and bending the connection part relatively to one end of the first end part; and the surface of the second end part is stuck on asystem circuit board so that the electronic element on the circuit board is electrically connected with the system circuit board through the connectors. The surface-mount circuit board piece module utilizes the surfaces of the bent second end parts of the connection parts to be mounted on the system circuit board so as to avoid various inconveniences caused by the arrangement of the system circuit board through the interposition technology.

Owner:DELTA ELECTRONICS INC

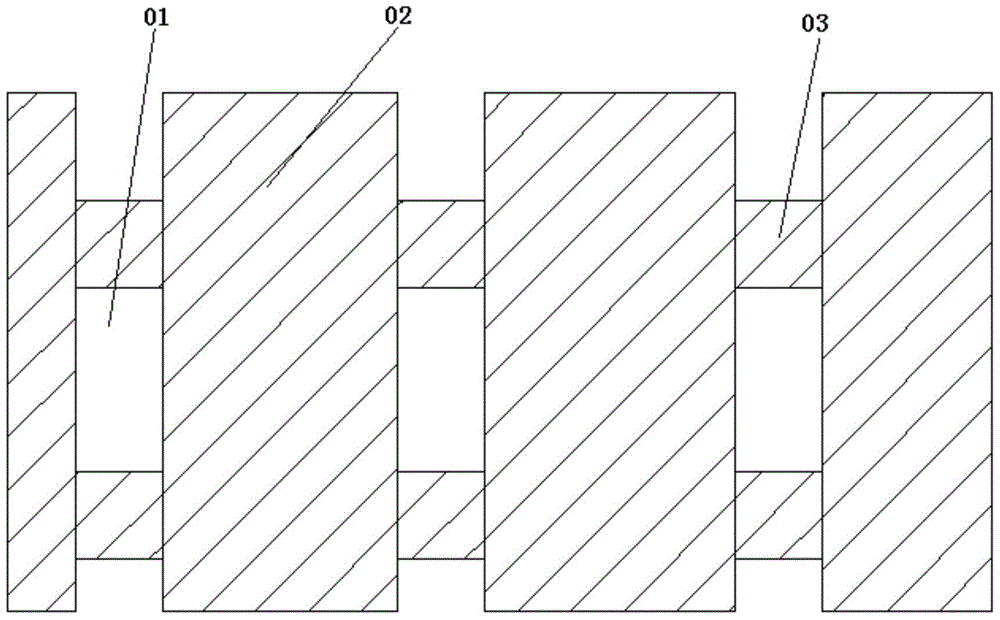

Spray head of MOCVD (metal organic chemical vapor deposition) equipment reactor and connection structure thereof

ActiveCN102691051BHigh strengthFlatness has no effectChemical vapor deposition coatingMetalPlasma-enhanced chemical vapor deposition

The invention aims to provide a spray head of an MOCVD (metal organic chemical vapor deposition) equipment reactor and a connection structure thereof so as to reduce the adverse influence of welding a bottom layer and a middle layer on a bottom surface. The spray head comprises a spray component and a top cover component, wherein the top cover component comprises a top cover; the spray component comprises a bottom layer, a middle layer and a top layer which are connected together; a cooling water channel and a cooling water cavity are formed between the bottom layer and the middle layer; a V-group gas cavity is formed between the middle layer and the top layer; a III-group cavity is formed between the top layer and the top cover; the bottom layer is an inward-concave integral member which is provided with a bottom wall and a corral side wall protruding from the bottom; and the outer side surface of the middle layer is welded with the inner side surface of the corral side wall of the bottom layer.

Owner:HANGZHOU SILAN AZURE

A kind of rubber hose automatic cutting equipment and rubber hose automatic cutting process

ActiveCN109227674BRealize automatic cuttingNot easy to scratchMetal working apparatusElectric machineGear wheel

The invention relates to automatic rubber hose cutting equipment and an automatic rubber hose cutting technology. The automatic rubber hose cutting equipment comprises a bottom plate, a supporting device and a cutting device, and the supporting device and the cutting device are sequentially installed on the bottom plate from left to right; the supporting device comprises a fixing plate, a fixed frame, a movable air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the cutting device comprises a linear guide rail, an electric sliding block, a working plate, aworking gear, a driving gear, a driving motor, a rotating ring, a rotating gear, a rotating motor, a supporting air cylinder, a supporting plate, a rotating rod, a sliding frame, a mounting frame, a cutting motor and a cutting blade. The invention further provides a using method of the automatic rubber hose cutting equipment. The equipment and the technology can solve the problems that in an existing rubber hose cutting process, the labor cost is high, the working efficiency is low, the cutting surface is not smooth, safety hidden hazards exist and the surface of a rubber hose is easily scratched, and the function of automatically cutting the rubber hose can be achieved.

Owner:中金液压胶管股份有限公司

Method for checking bacterial number after filtering using filtering film

InactiveCN101008028AReduce pollutionImprove accuracyMicrobiological testing/measurementMaterial resourcesColony counting

The invention discloses a method for counting bacteria after filtering with filter membrane. It comprises following steps: filtering sample on filter membrane to make the bacteria in sample be cutted off on filter membrane, pouring solid or semi- solid culture medium on the back surface of bacteria- containing filter membrane, culturing, and colony counting. The temeprature of said solid pr semi- solid culture medium is not larger than 45 Deg. C, and it is in flow state during pouring. The invention is characterized in that it is unecessary for filter membrane to be shifted after filtering, which reduces pollution caused during filter membrane shift and obviously increases result accuracy; it avoids bubble generation and space between filter membrane and culture medium, and free from influence of planeness of filter membrane and operational technology; solves problems of unstable pad pasting and slide filter membrane, and greatly reduces manual effort, material resources and time.

Owner:叶大林

Construction method for surface reinforcement treatment after pouring of building foundation

ActiveCN111206632BNo gapsImprove building safetyFoundation repairArchitectural engineeringElectric machinery

Owner:大庆珑达建工集团有限公司

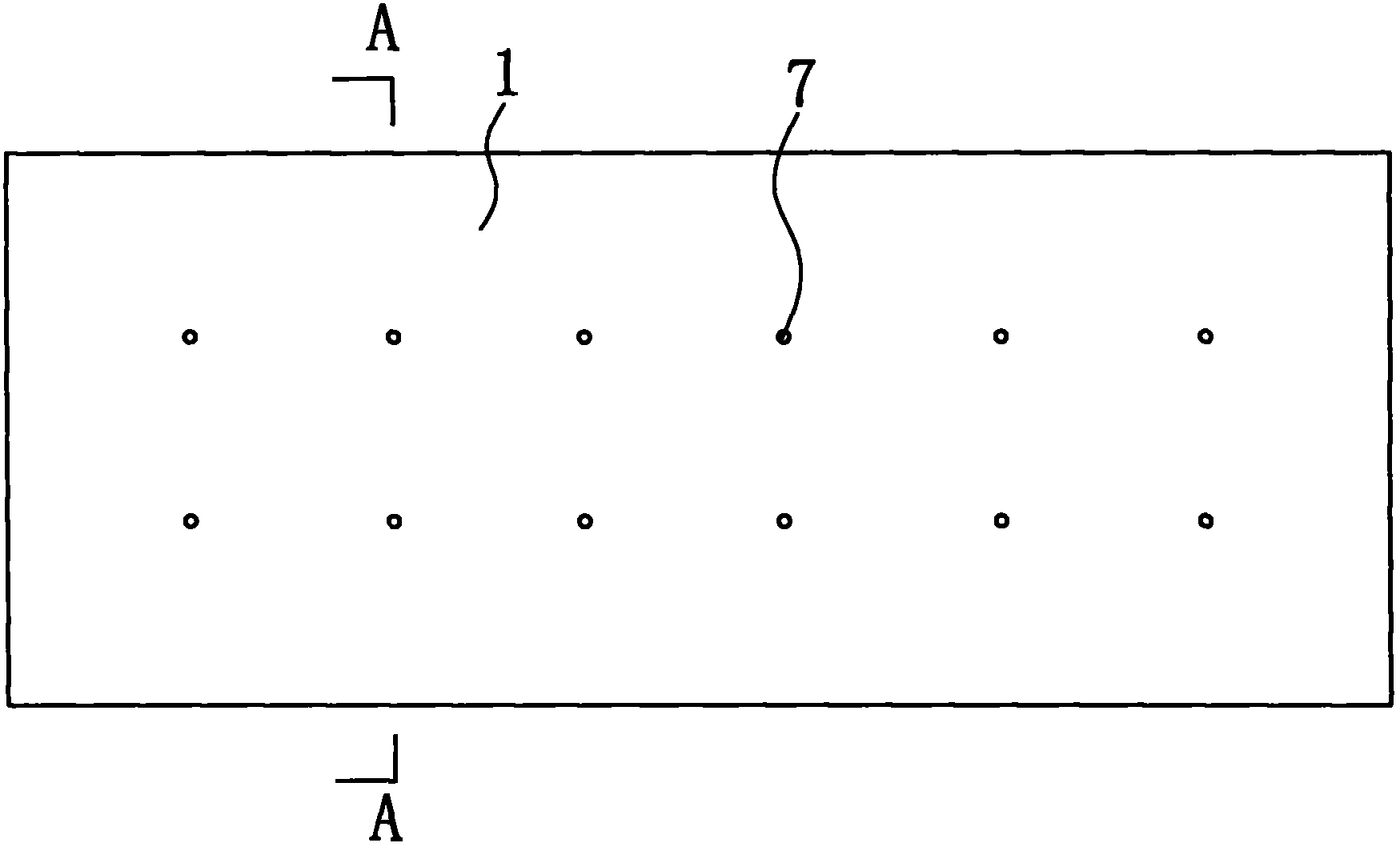

Supporting structure of low cast-in-place capping beam and construction method thereof

PendingCN110424251AImprove structural stabilityEasy to removeBridge structural detailsBridge erection/assemblyStructural engineeringPlastic film

The invention relates to a supporting structure of a low cast-in-place capping beam and a construction method thereof. The supporting structure comprises a concrete cushion ply, a sand box, a plasticfilm and a bottom template arranged successively from bottom to top. The sand box comprises a frame, a split bolt and fine sand filler. The frame comprises two longitudinal frame strips and two transverse frame strips, a plurality of through holes are separately formed in corresponding positions of the two longitudinal frame strips, the split bolt comprises a split screw provided with threaded parts at two ends and two nuts, the split screw penetrates the frame and the thread parts of the split screw stretch out of the longitudinal frame strips through the through holes, the nuts are arrangedon the thread parts in a sleeving manner and are tightened till the nuts are compressed to the longitudinal frame strips, an inner cavity of the frame is fully filled with the fine sand filler, the top surface of the fine sand filler is aligned with the top surface of the frame, the plastic film covers the top surface of the sand box, the bottom template is arranged on the plastic film, and the capping beam is poured to the bottom template. According to the invention, the low cast-in-place capping beam can be constructed in a narrow space, disturbance to a soil body below is small, and the supporting structure is simple to construct and detach without affecting the safety of the structure below the soil body.

Owner:广州市第三市政工程有限公司

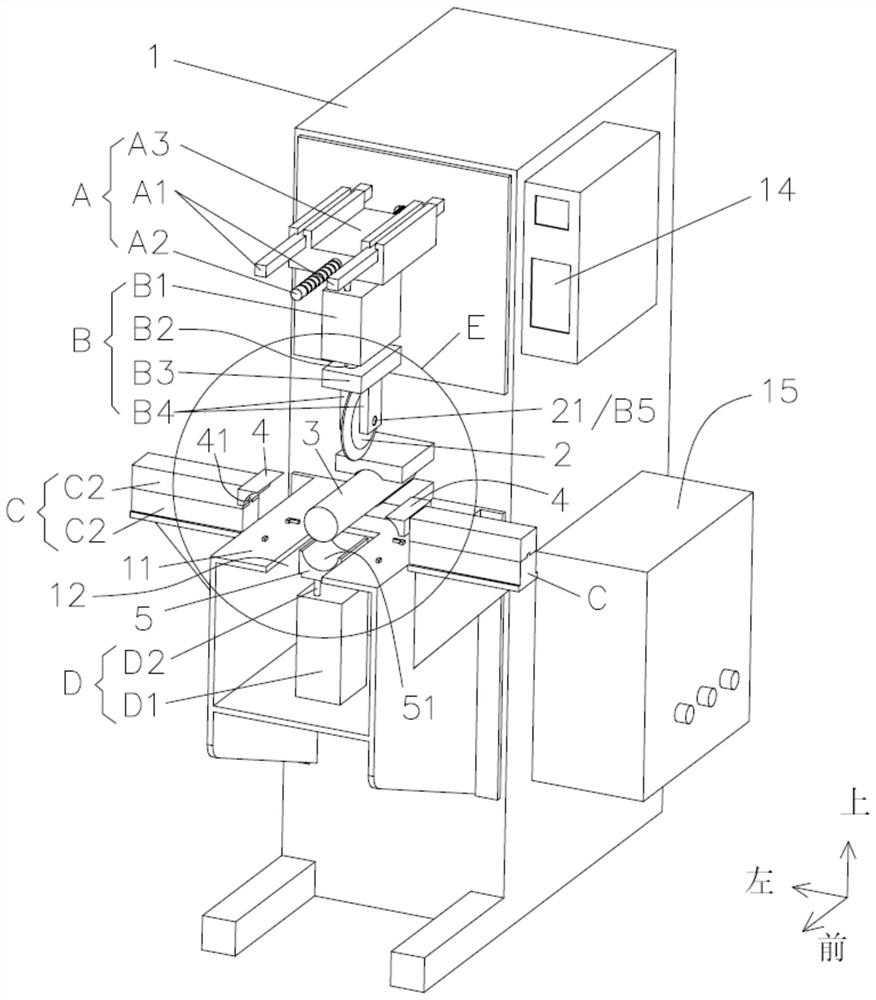

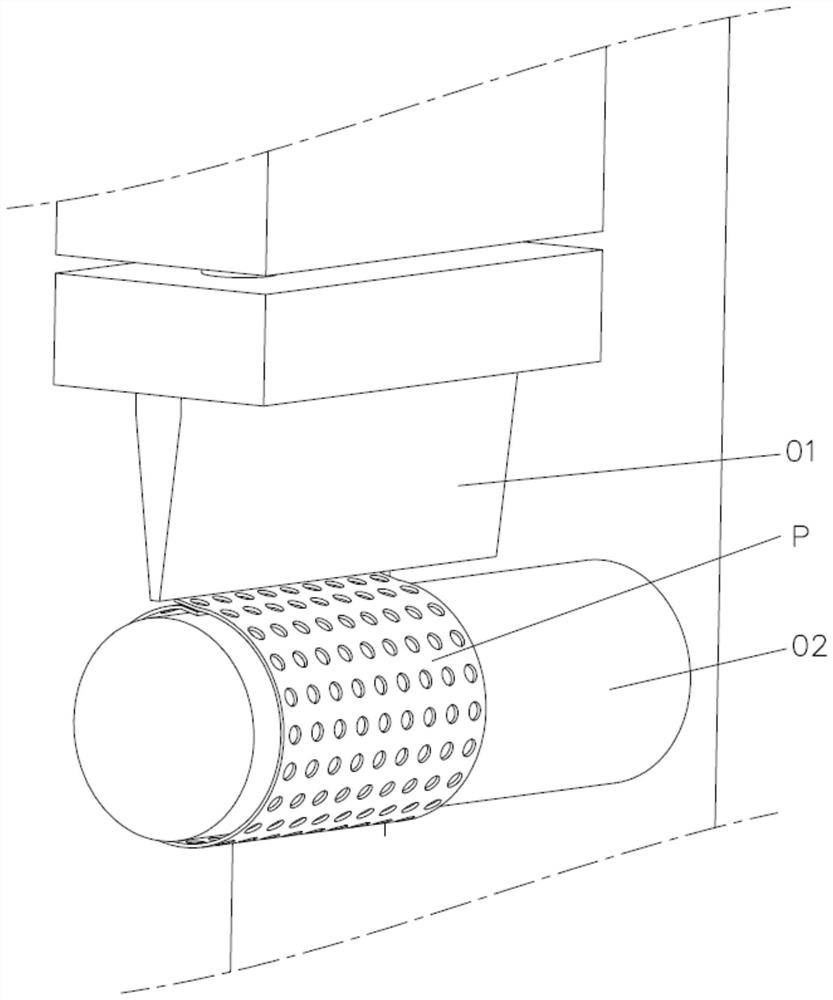

A method of manufacturing a cylindrical straight seam workpiece

ActiveCN112518235BPrecise positioningEffect of flatnessResistance electrode holdersStampingStructural engineering

A method for manufacturing a cylindrical straight seam workpiece, using a resistance welding machine, including a welding wheel, a support table, a cylindrical lower welding electrode, left and right stamping dies and a lower stamping die, the left and right circular arc stamping dies and the lower round Arc stamping dies can be spliced into cylinders with welded gaps. The process steps include: 1) placing the plate on the support table, 2) driving the lower stamping die to push the plate to the lower electrode, and the plate forms the lower half of the cylinder under the extrusion of the lower stamping die and the cylindrical lower electrode arc, 3) drive the left and right stamping dies to move towards each other, and the plate is squeezed by the left and right stamping dies and the cylindrical lower welding electrode to form the upper half arc of the cylinder; 4) drive the welding wheel to press down on the cylinder At the intersection, 5) the welding wheel and the lower electrode are energized, and the welding wheel is driven to move from back to front along the intersection of the cylinder, and the overlapping plates at the intersection of the cylinder are fused, 6) the welding wheel, the left and right circles The arc stamping die and the lower arc stamping die are reset, and the workpiece is taken away.

Owner:江门市亿高电器有限公司

Resistance welding machine capable of automatically rolling plates

PendingCN112355455APrecise positioningEffect of flatnessResistance welding apparatusStampingStructural engineering

The invention discloses a resistance welding machine capable of automatically rolling plates. The resistance welding machine comprises a rack, a rotating welding wheel is arranged in front of the rack, the welding wheel is connected with a front-back sliding device and a first lifting device, a cylindrical lower welding electrode extending in front of the rack is arranged below the welding wheel,and a left arc stamping die and a right arc stamping die are arranged on the left side and the right side of the lower welding electrode correspondingly. The left arc stamping die and the right arc stamping die are connected with a left sliding device and a right sliding device correspondingly, a lower arc stamping die is arranged below the lower welding electrode, a second lifting device is connected below the lower stamping die, and the left arc stamping die, the right arc stamping die and the lower arc stamping die can be spliced into a cylinder with a welding gap. The resistance welding machine capable of automatically rolling the plates has the advantages of simple process, accurate workpiece positioning, high production efficiency, good welding quality and the like.

Owner:江门市亿高电器有限公司

Aluminum alloy cutting equipment for door and window production

InactiveCN113681068AGuaranteed accuracyReduce labor intensityShearing machinesMaintainance and safety accessoriesStructural engineeringManufacturing engineering

The invention belongs to the field of door and window production, and particularly relates to aluminum alloy cutting equipment for door and window production. The aluminum alloy cutting equipment comprises a base, a fixing plate is fixedly mounted at the top of the base, a supporting column is connected to the top of the fixing plate, a lifting column is connected to the outer wall of the supporting column, and a top plate is fixedly connected to the top of the lifting column. According to the aluminum alloy cutting equipment, after cutting is completed, cut aluminum alloy profiles can be guided into a notch in a pushing mode, then aluminum alloy profile grooves can be guided into a storage frame under the guiding effect of a first limiting rod and a second limiting rod, manual operation is not needed, under effective limiting, the aluminum alloy profiles can be stacked in order, and meanwhile, along with the cutting adjustment of different lengths, a second limiting rod can also be adjusted along with the cutting adjustment of different lengths, so that the limiting accuracy of the cut profile is effectively guaranteed, the labor intensity of workers can be greatly reduced, integrated operation is achieved, and the cutting efficiency is effectively improved.

Owner:徐州市固塑建筑材料有限公司

LNG ship pump tower base helium test method

PendingCN113884252AImprove construction efficiencyEasy to operateDetection of fluid at leakage pointMarine engineeringTower

The invention discloses an LNG ship pump tower base helium test method. According to the method, two helium test tools are arranged on a pump tower base, and the two helium test tools are used for helium test, so that the efficiency of the method is improved by more than one time, the working difficulty is reduced, the manpower consumption is reduced, the construction time is greatly reduced, and the building efficiency of the ship is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com