Road engineering pavement leveling machine

A leveling machine and engineering technology, applied in the field of road leveling, can solve problems such as road surface quality degradation, bulging, shortening the service life of the road surface, etc., to achieve the effect of improving leveling adequacy, ensuring quality, and flexibly repairing leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

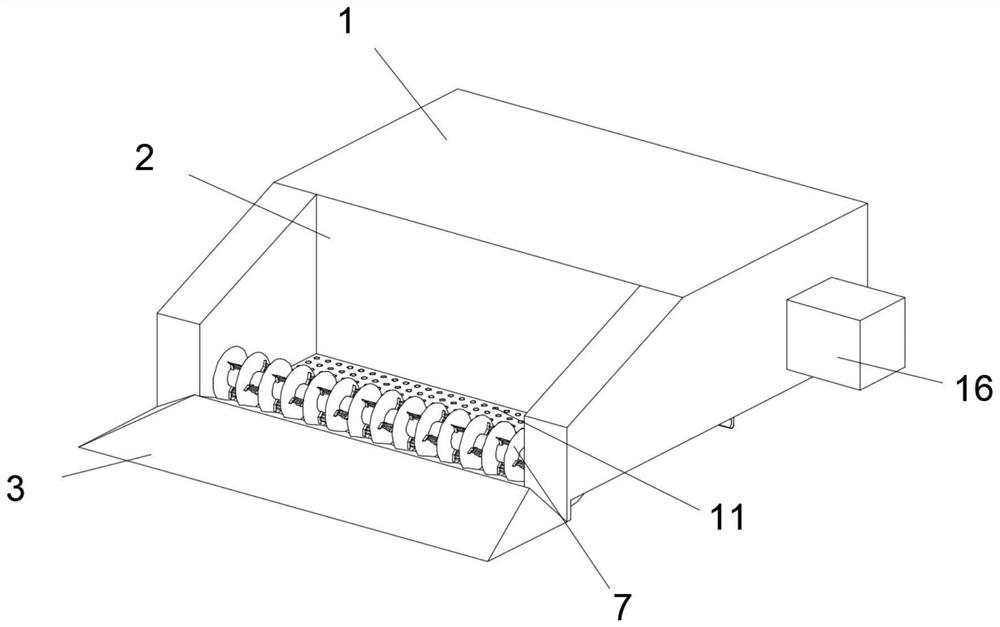

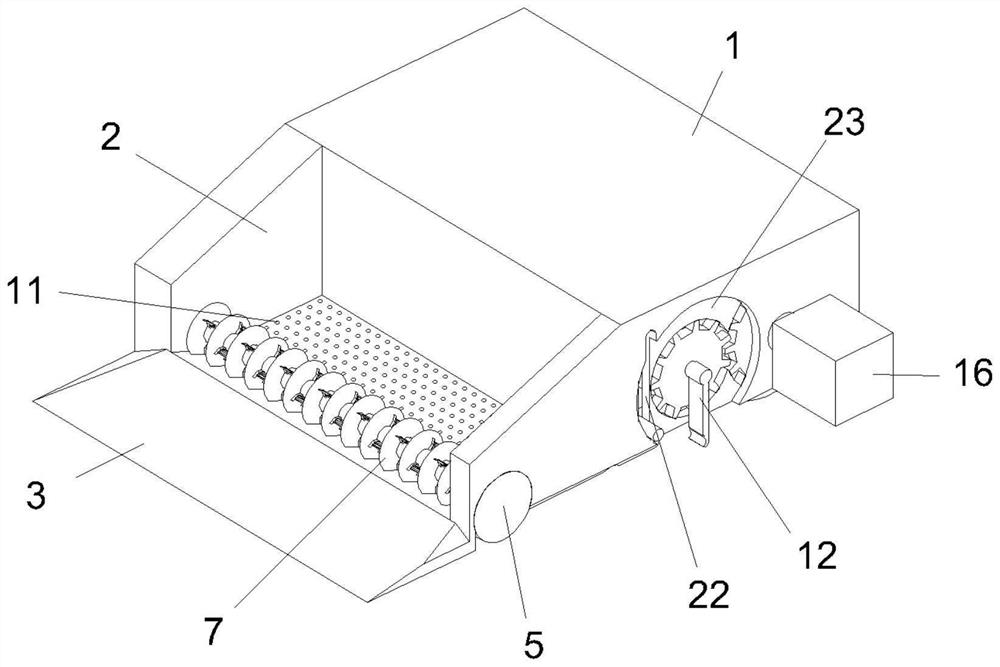

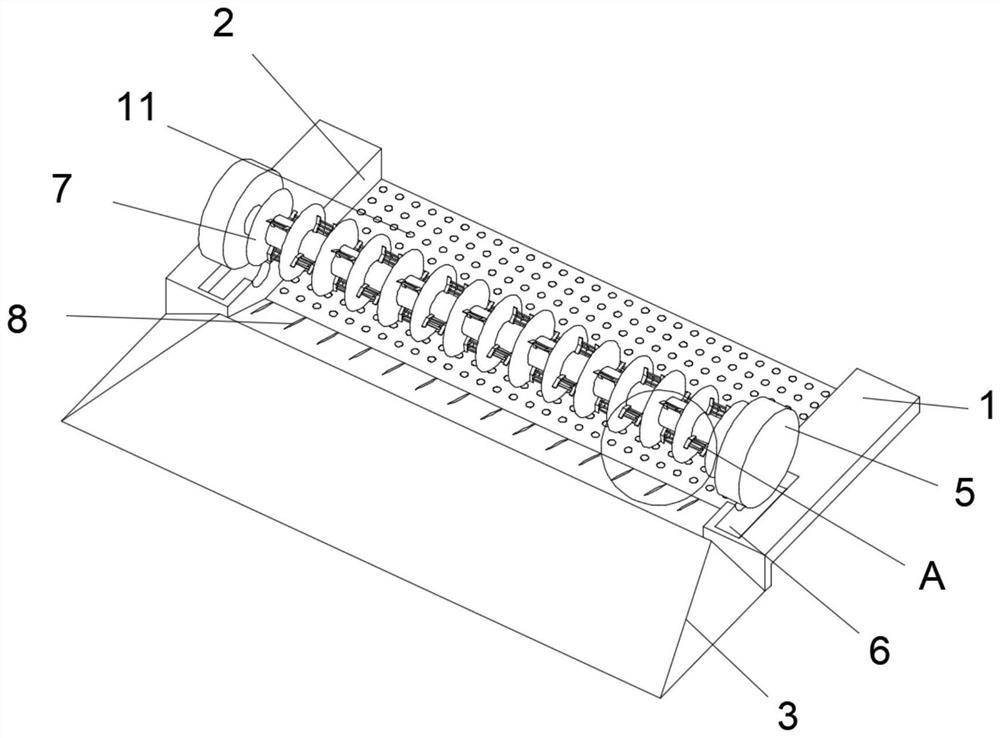

[0029] see Figure 1-7 , the present embodiment provides a road leveling machine for road engineering, comprising a mobile seat 1, a collection tank 2 is provided on the upper part of the front wall of the mobile seat 1, a shovel plate 3 is fixed at the lower end of the front wall of the mobile seat 1, and the front wall of the mobile seat 1 The upper end is also fixed with a feed baffle, and the feed baffle, the shovel and the side wall of the collection tank form a crushing channel, that is, the soil shoveled by the shovel 3 enters the collection tank from the crushing channel, and the moving seat The position of the front part relative to the front side of the collection tank 2 is provided with a roller 4 running through the crushing channel, and the two ends of the roller 4 are symmetrically and coaxially fixedly connected with a roller 5, and the bottom surface of the moving seat 1 is provided with a bottom relative to the position of the roller 5 Groove 6, the middle par...

Embodiment 2

[0045] The difference between this embodiment and the technical solution of Embodiment 1 is that, in this embodiment, no roller is provided outside the roller, and the rotation of the roller is realized by a transmission mechanism arranged between the wheel and the roller.

[0046] Wherein the transmission mechanism can be belt and pulley transmission, and also can be transmission through bevel gears and connecting rods.

[0047] That is to say, in Embodiment 1, the wheel shaft and the ground breaking wheel on it rely on the friction between the roller and the ground for transmission, and there may be situations where the roller and the ground slip during actual use. And in the present embodiment, the rotation of the roller and the earth-breaking wheel, the soil-breaking teeth and the blades are all driven by the rotation of the wheel shaft, which avoids the possible slipping situation and improves the efficiency of breaking the soil and crushing the soil. At the same time, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com