Bottom plate wax mold structure and forming method of directional solidification shell bottom plate

A technology of directional solidification and molding methods, applied in the direction of casting mold components, casting molding equipment, casting molds, etc., to achieve the effects of preventing shrinkage deformation, good buffer support, and preventing unevenness of the bottom surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

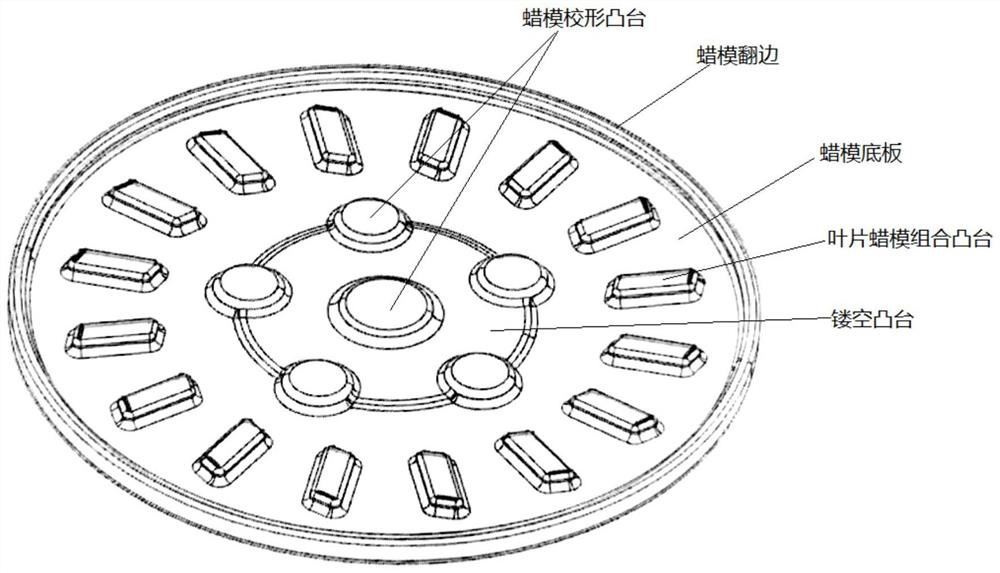

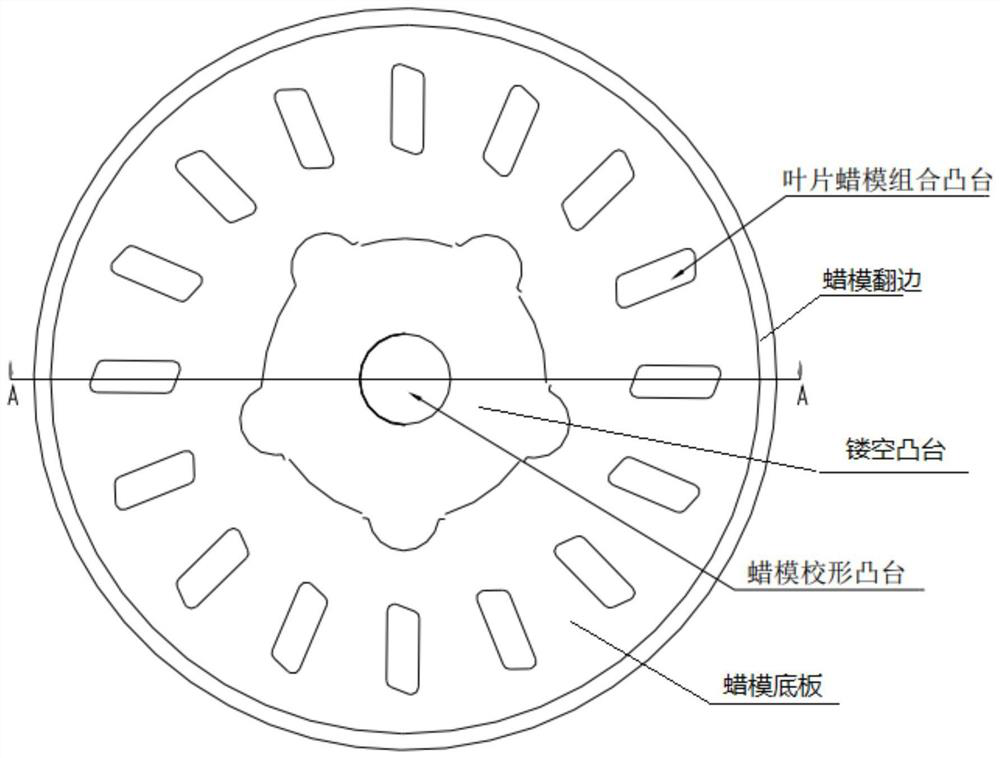

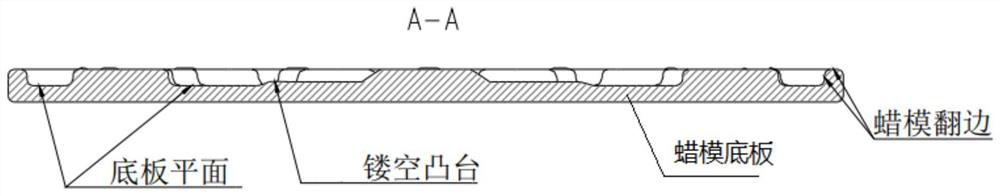

[0038] Such as Figure 1 to Figure 3 As shown, the preferred embodiment of the present invention provides a base plate wax pattern structure, the base plate wax pattern structure is used for the molding of directionally solidified shell bottom plate, and it comprises wax pattern bottom plate, wax pattern flanging, blade wax pattern combination boss 1. Wax mold shaping bosses and hollow bosses, the wax mold bottom plate is flat and disc-shaped, used to form the plane of the directionally solidified shell bottom plate, and the wax mold flanging is arranged on the edge of the wax mold bottom plate along the circumferential direction Above, the inner diameter surface of the wax pattern flanging is used to form the circumference of the directionally solidified shell bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com