Fused quartz metallurgic roller

A technology of fused silica and ceramic sleeves, which is applied in the field of metallurgical rolls, can solve the problems of easy deformation of steel rolls, deviation of goods, and scratches on the metal plate surface, so as to achieve the effect of not being easy to shift and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

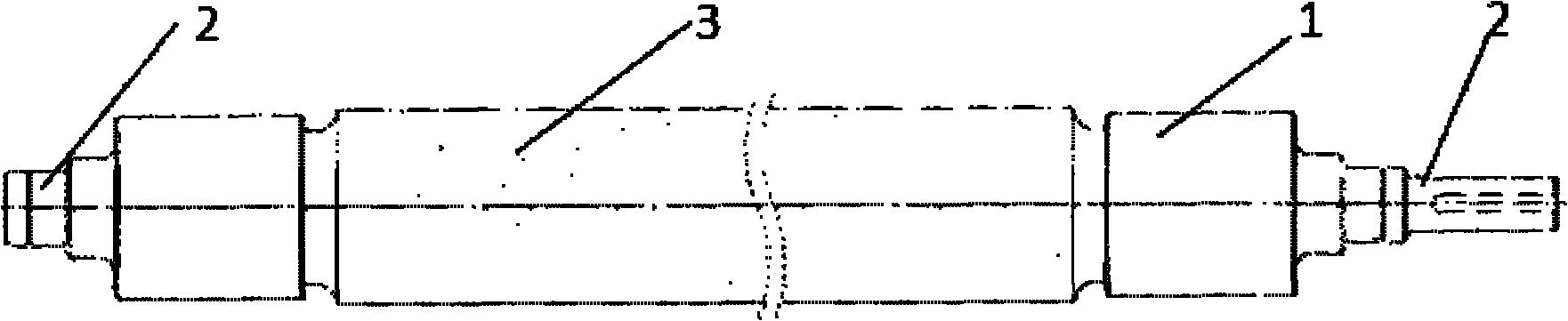

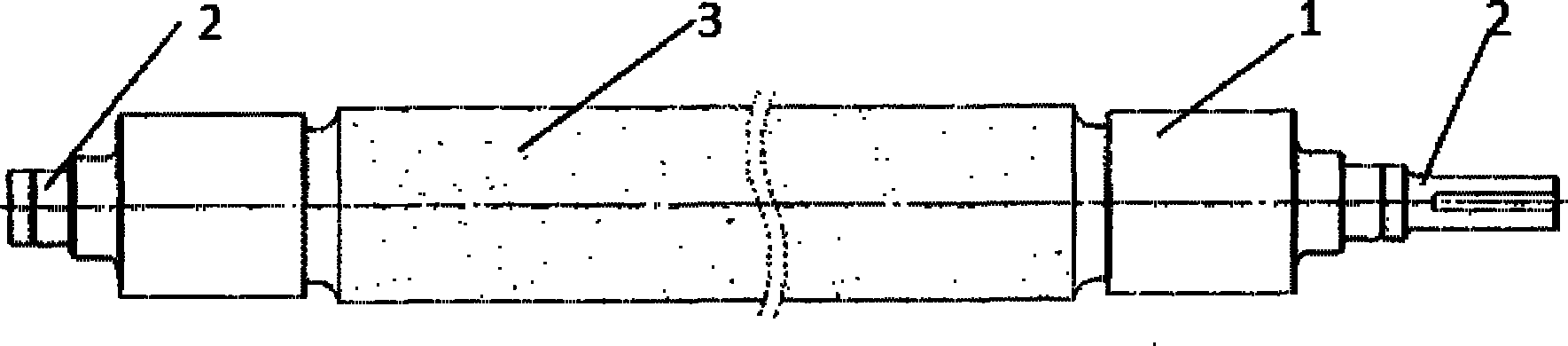

[0013] The invention discloses a fused silica metallurgical roller, such as figure 1 As shown, it includes a ceramic sleeve 1, a steel shaft 2 passing through the ceramic sleeve 1, and the outer surface of the ceramic sleeve 1 is provided with a sandblasting layer 3 with a thickness of 4-20 microns. In order to increase the strength of the roller, the ceramic sleeve 1 adopts a hollow fused silica sleeve.

[0014] The metallurgical roller of the present invention adopts fused quartz instead of steel roller or mullite roller, which increases the strength of the roller, and due to the design of sandblasting on the outer surface of the casing, the goods are not easy to shift on the roller. The flatness of the sheet metal surface will not be affected.

[0015] The present invention still has many specific implementation modes, and all technical solutions formed by adopting equivalent replacement or equivalent transformation all fall within the protection scope of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com