Preparation method of high-opening-ratio mask board and mask board

A mask and aperture ratio technology, applied in the field of mask and mask preparation, can solve the problems of low aperture ratio, inability to achieve high-resolution screen evaporation, etc., to achieve increased aperture ratio and complete protection The effect of ensuring the accuracy of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

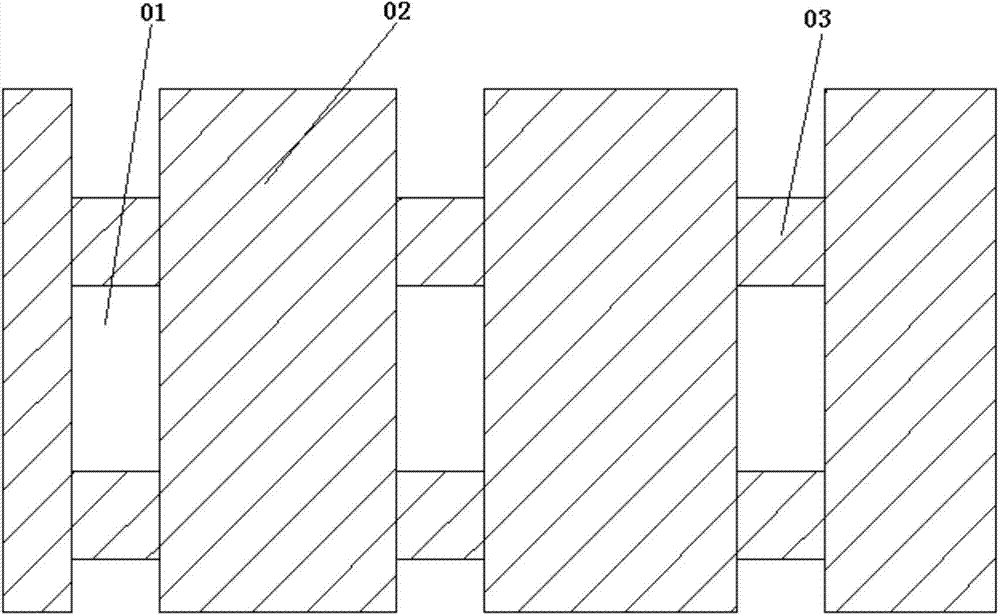

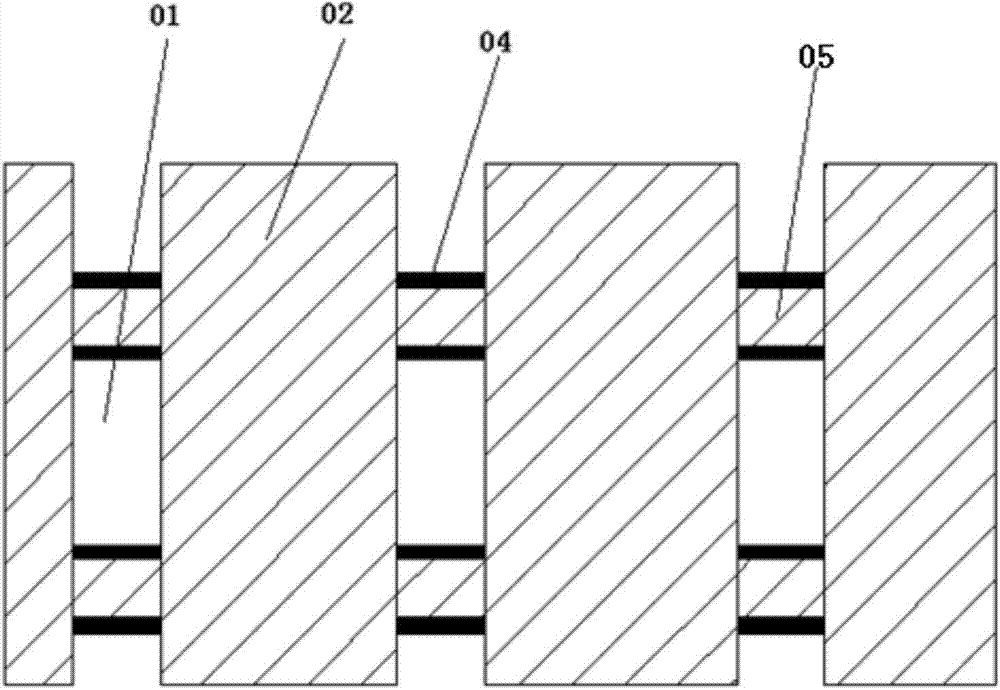

[0031] Such as figure 2 and image 3 As shown, the preparation method of a high aperture ratio mask plate related to the present invention comprises the following steps:

[0032] S1: Coating light-curing material on the surface of the mask plate, and curing the light-curing material in the main area 02 of the mask plate and the connecting bridge reserved area 05 to form a low polymer, and cleaning with alcohol to remove the bridge to be corroded area 04 Light-curing materials whose surface has not been cured;

[0033] S2: Immerse the mask plate coated with low polymer prepared in step S1 into FeCl with a concentration of 80-95% 3 Solution, soaked for 30-300 seconds under the condition of energized voltage of 70-100v to remove the connecting bridge to be corroded area 04, and obtain a mask plate coated with a low polymer; the low polymer is polyimide .

[0034] S3: The mask plate coated with the low polymer is placed in a solution of dimethylacetamide and soaked for 15-25 ...

Embodiment 2

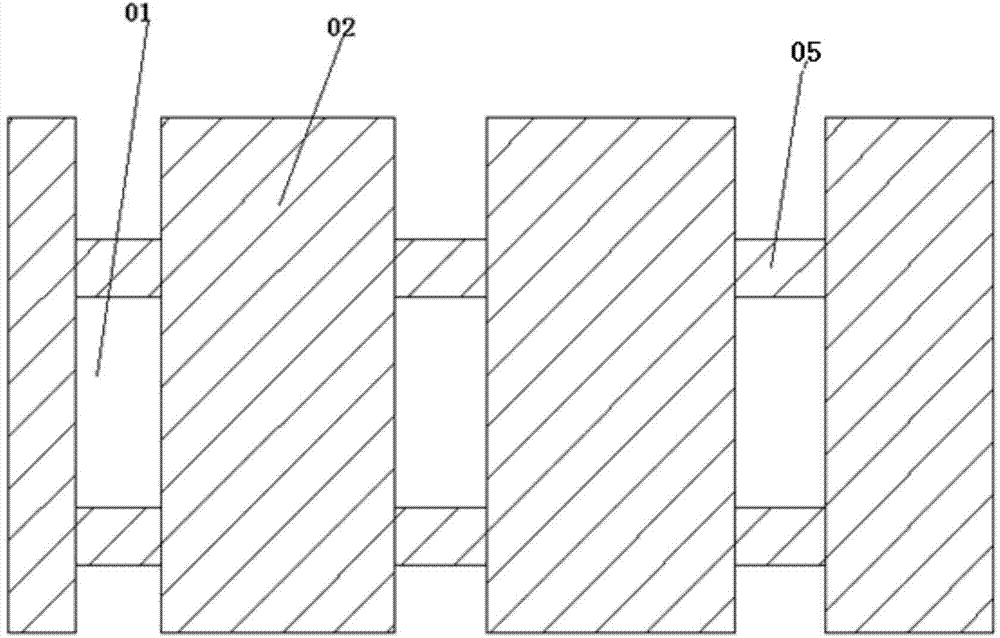

[0039] Another embodiment of the present invention is as Figure 4 As shown, a method for preparing a mask plate with a high aperture ratio of the present invention comprises the following steps:

[0040] S1: Coating light-curing material on the surface of the mask plate, and curing the light-curing material in the main area 02 of the mask plate and the connecting bridge reserved area 05 to form a low polymer, and cleaning with alcohol to remove the bridge to be corroded area 04 Light-curing materials whose surface has not been cured;

[0041] S3, immerse the mask plate coated with the low polymer prepared in step S2 into FeCl with a concentration of 80-95% 3 Solution, soaked for 30-300 seconds under the condition of energized voltage of 70-100v to remove the connecting bridge to be corroded area 04, and obtain a mask plate coated with a low polymer; the low polymer is polyimide .

[0042] S4: The mask plate coated with the low polymer is placed in a solution of dimethylace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com