Decorative wall with ultrathin oversized indoor decorating plates and construction method thereof

A technology for interior decorative panels and decorative panels, which is used in underground chambers, shaft equipment, earth-moving drilling, etc., can solve problems such as inability to guarantee construction quality and safety, inconvenience in cross-construction, and empty drums of waterproof latex paint, etc. Long-term paint quality, good firmness and safety, avoid inconvenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

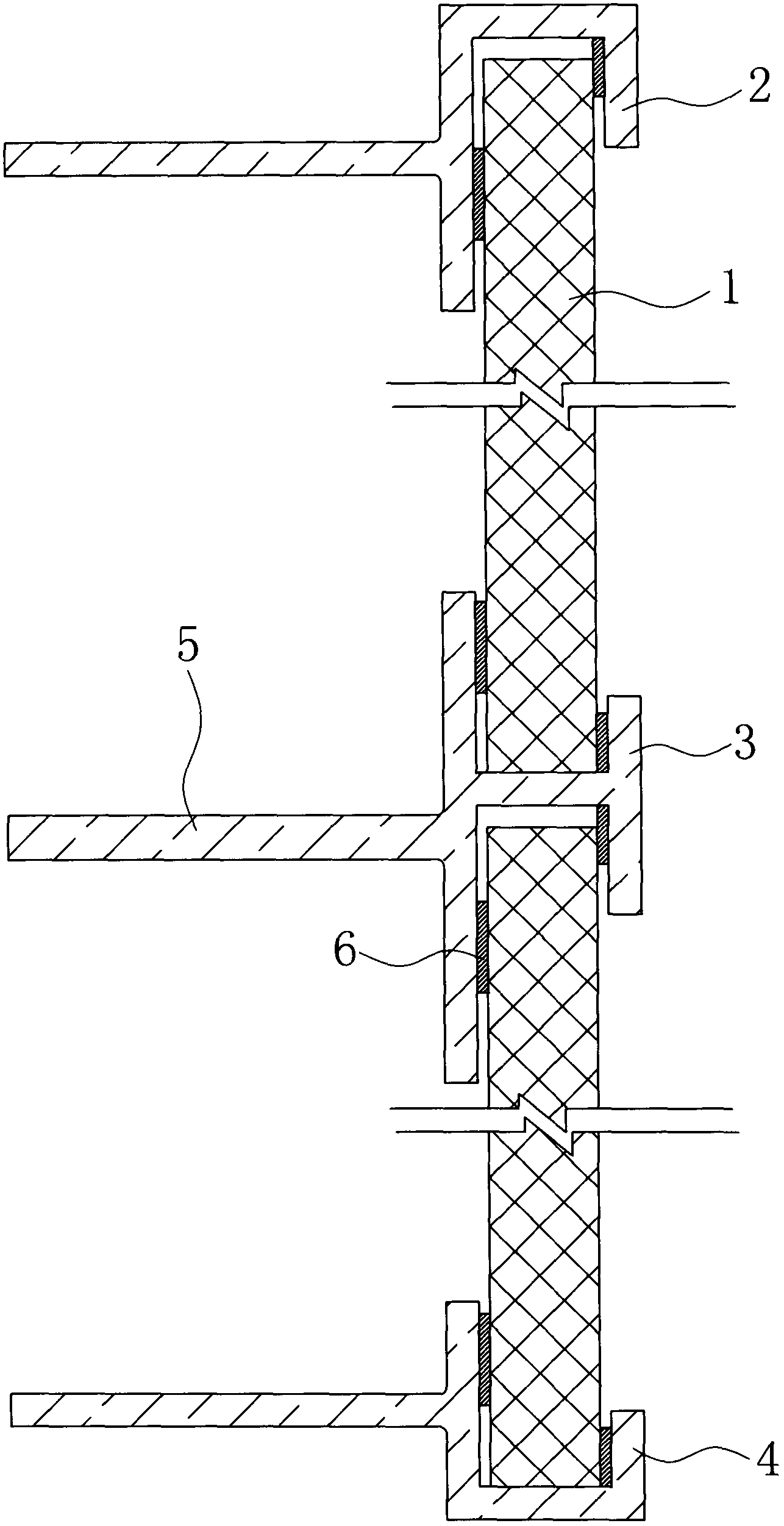

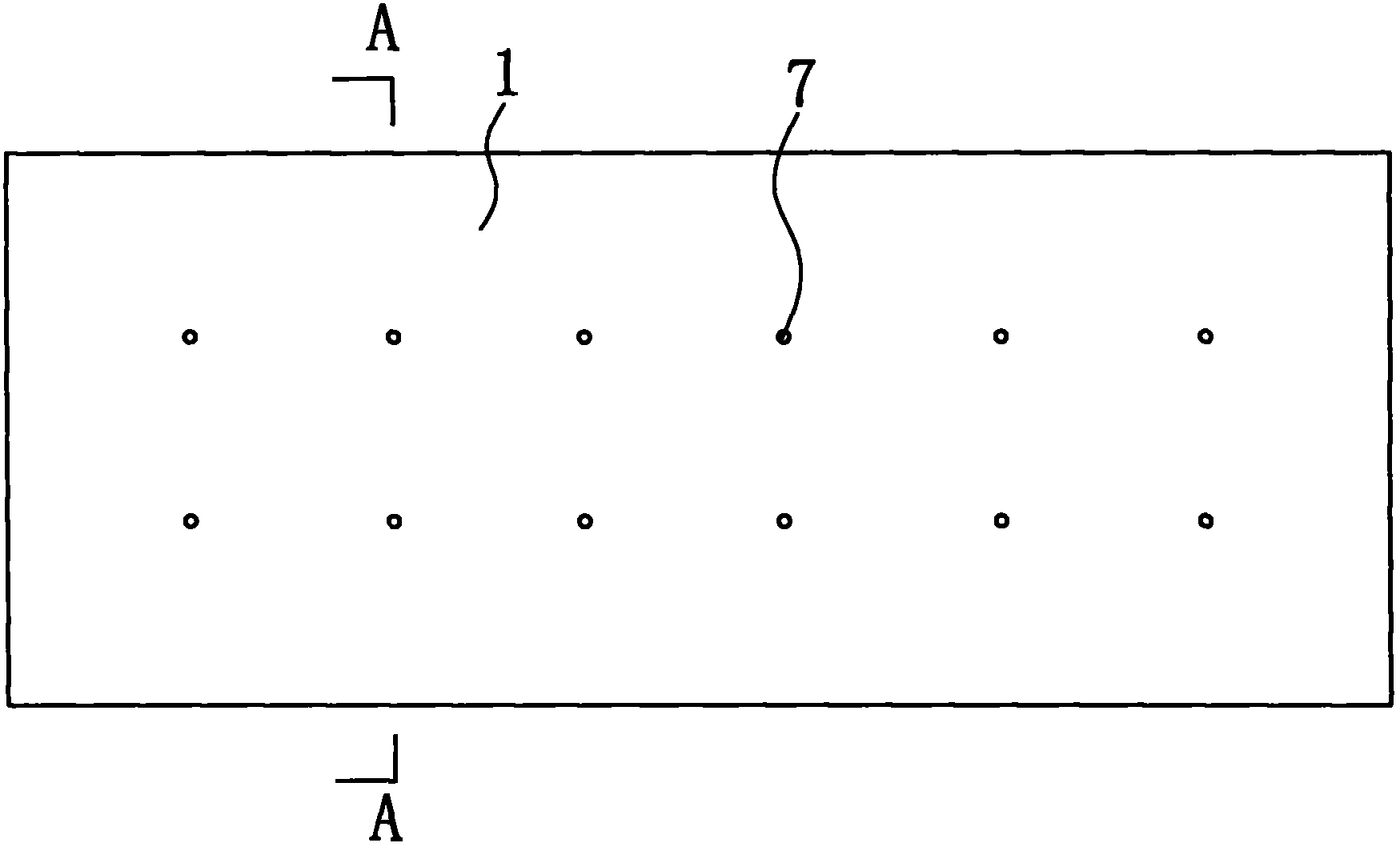

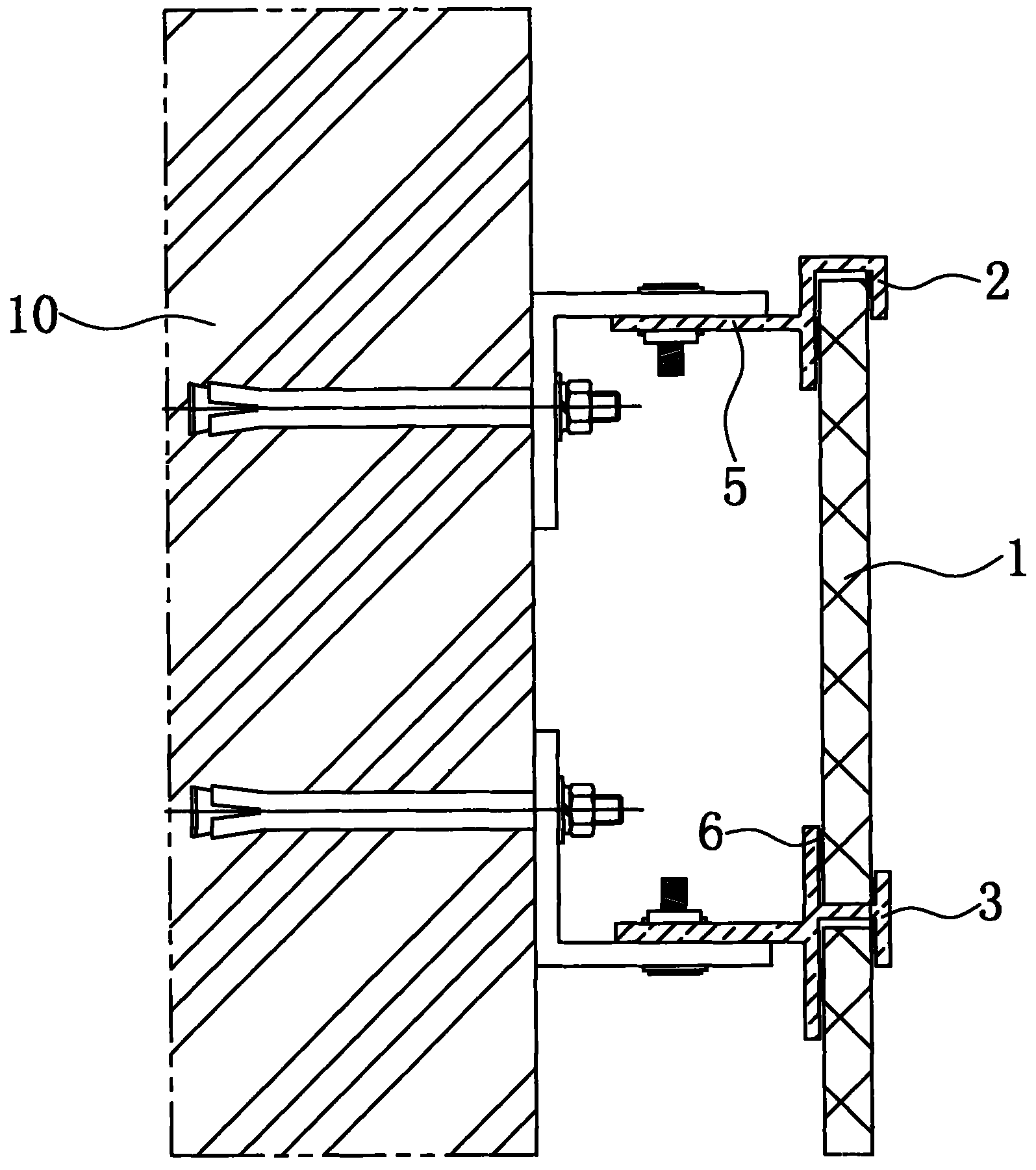

[0036] Embodiment one: see Figure 1~5 As shown, a decorative wall of ultra-thin and super-large interior decorative panels includes a longitudinal keel assembly connected to the wall body 10, a horizontal keel assembly connected with the longitudinal keel assembly, and a decorative panel 1 installed on the horizontal keel assembly. The transverse keel assembly is composed of an upper keel 2, at least one middle keel 3, and a lower keel 4. One end of the upper keel 2 and the lower keel 4 are respectively provided with a receiving groove for clamping the decorative panel 1, and the other end is a The horizontal bar 5 connected to the longitudinal keel assembly is in the shape of "F", and the openings of the accommodating grooves of the upper 2 and lower keel 4 are opposite to each other; , and the other end is a cross bar 5 connected with the longitudinal keel assembly, which is in the shape of "shi".

[0037] In this embodiment, the decorative board 1 is a calcium silicate bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com