Surface-mount circuit board piece module and preparation method thereof

A surface mount type, circuit board technology, applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, etc., can solve the problem of broken connectors, cumbersome and time-consuming processing steps, and reduce the quality of electronic devices. Ratio and other issues to achieve the effect of flexible configuration, avoiding impact, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention is capable of various changes in different forms without departing from the scope of the present invention, and that the description and drawings are illustrative in nature and are not intended to limit the present invention.

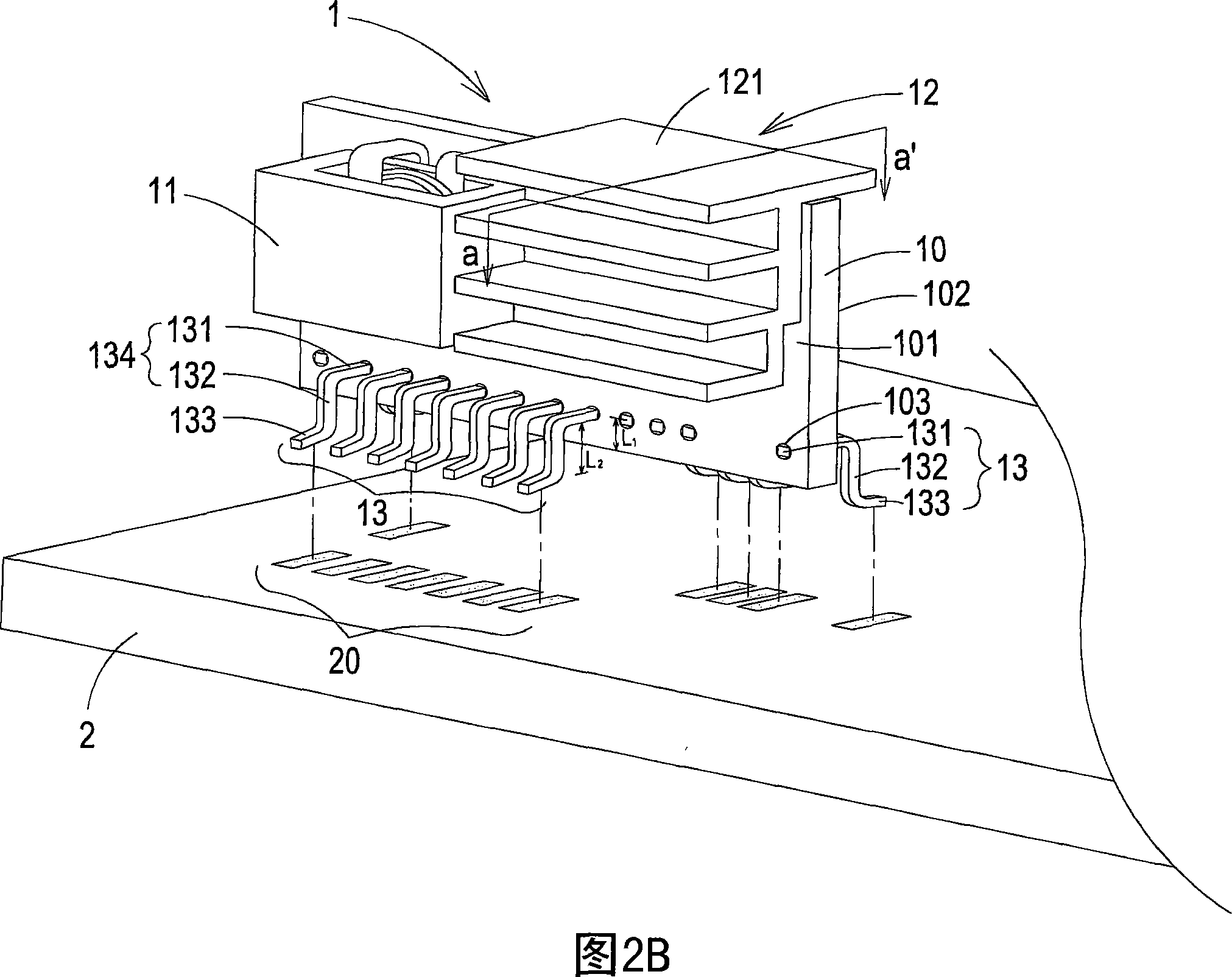

[0039] The surface-mounted circuit board module of the present invention is disposed on the system circuit board of an electronic device (not shown) by surface mount technology (SMT), and the surface-mounted circuit board module of the present invention can be a power module (power module), etc., but not limited thereto.

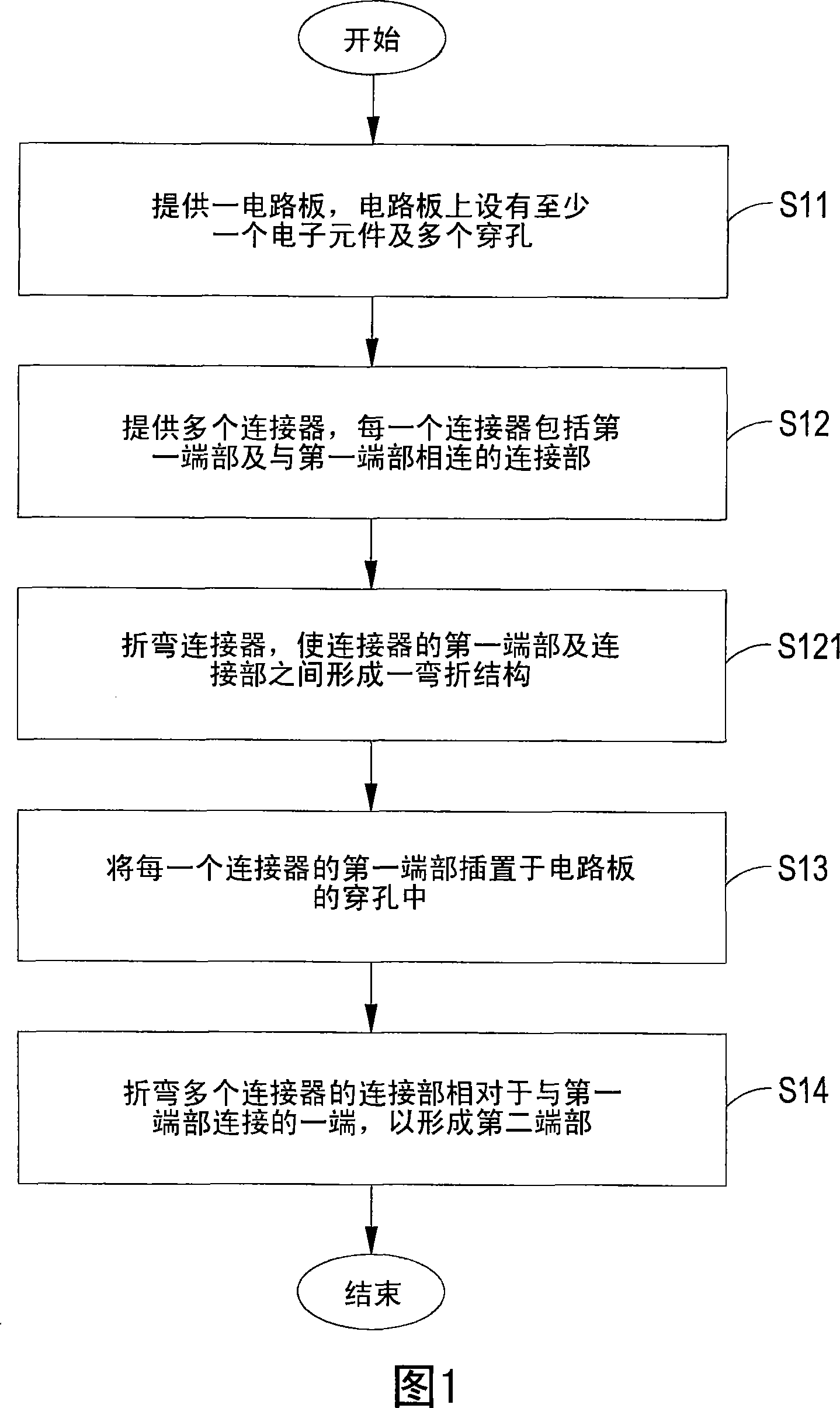

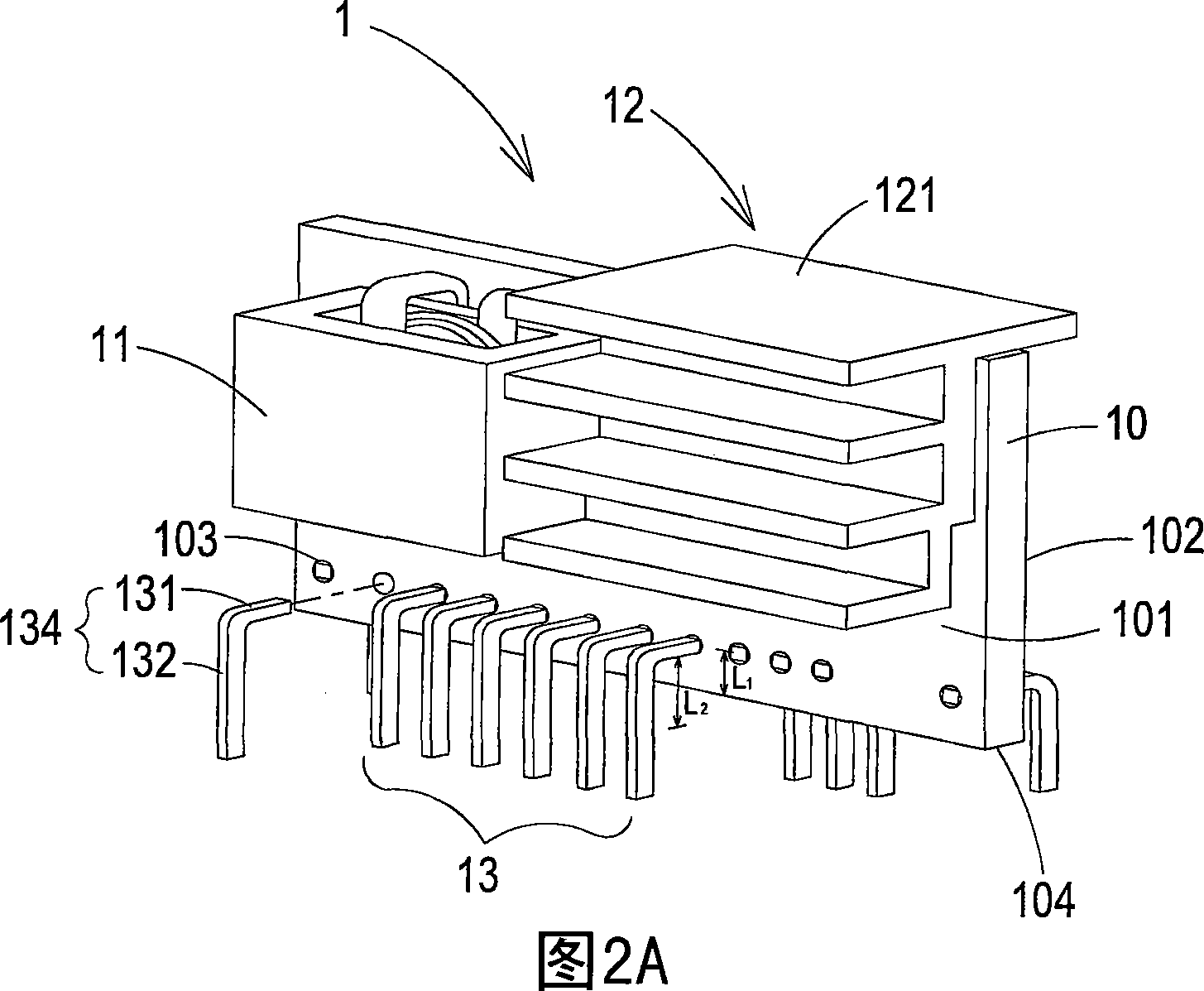

[0040] see figure 1 and cooperate Figure 2A , which are respectively the flow chart and assembly diagram of the surface-mounted circuit board module of the first preferred embodiment of the present invention. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com