Sectioning equipment for plastic binding rope

A technology of bundling ropes and cutting sections, applied in the direction of metal processing, etc., can solve the problem of uneven cutting surface and achieve the effect of smooth cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

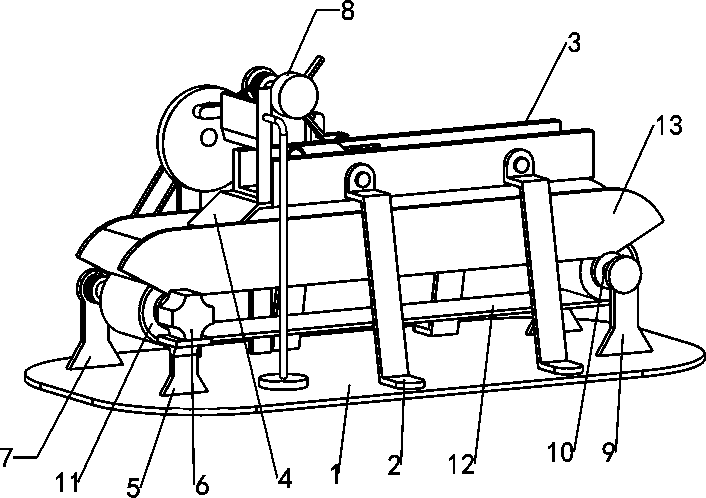

[0021] A cutting device for plastic strapping ropes, such as Figure 1-2 As shown, it includes a base 1, a support frame 2, a placement frame 3, a slant plate 4, a first bearing seat 5, a servo motor 6 and a cutting mechanism 7, and the support frame 2 is fixedly connected to the front and rear sides of the top of the base 1, and the support frame 2 The upper part is connected with a placement frame 3 by bolts, the left side of the placement frame 3 is fixedly connected with a slant plate 4, the top left front side of the base 1 is provided with a first bearing seat 5, the top of the first bearing seat 5 is installed with a servo motor 6, and the base 1 is provided with a cutting mechanism 7, and the output shaft of the servo motor 6 is connected with the cutting mechanism 7.

[0022] The cutting mechanism 7 includes a second bearing seat 70, a first rotating shaft 71, a third bearing seat 72, a second rotating shaft 73, a first pulley 74, a second pulley 75, a flat belt 76, a...

Embodiment 2

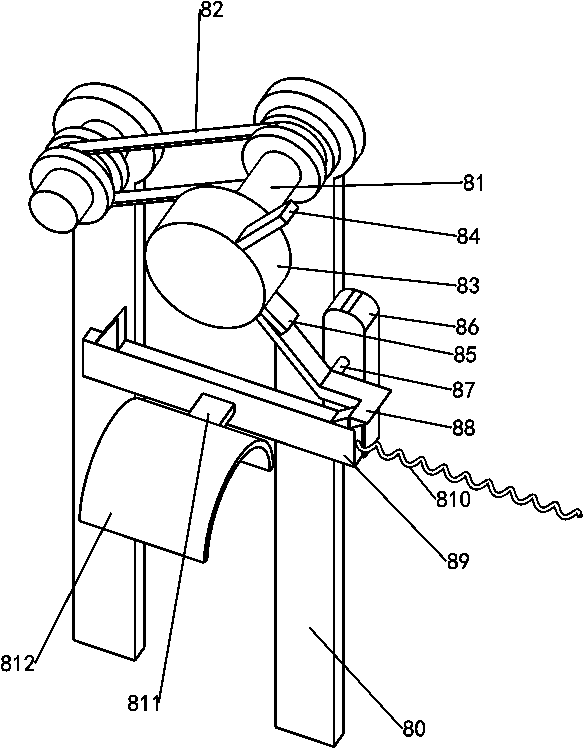

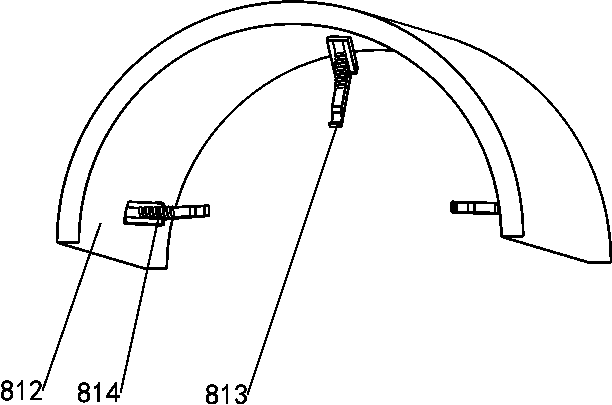

[0026] On the basis of Example 1, such as figure 1 and Figure 3-4As shown, it also includes a repeating displacement mechanism 8, the middle of the top of the base 1 is provided with a repeating displacement mechanism 8, and the repeating displacement mechanism 8 includes a fourth bearing seat 80, a third rotating shaft 81, a transmission assembly 82, a second turntable 83, a first Toggle lever 84, the second toggle lever 85, the fifth bearing seat 86, the fourth rotating shaft 87, special-shaped block 88, slide block 89, first spring 810, connecting block 811, arc plate 812, driving lever 813 and the first Two springs 814, a fourth bearing seat 80 is installed on the rear side of the top of the base 1, the fourth bearing seat 80 is located on the right side of the third bearing seat 72, and the fourth bearing seat 80 is internally rotated to be provided with a third rotating shaft 81, and the third rotating shaft 81 The rear part is provided with a transmission assembly 82,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com