Liftable and movable type optical glass cutting device

A technology for optical glass and cutting devices, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as uneven cutting surfaces, achieve flat cutting surfaces, ensure stability, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

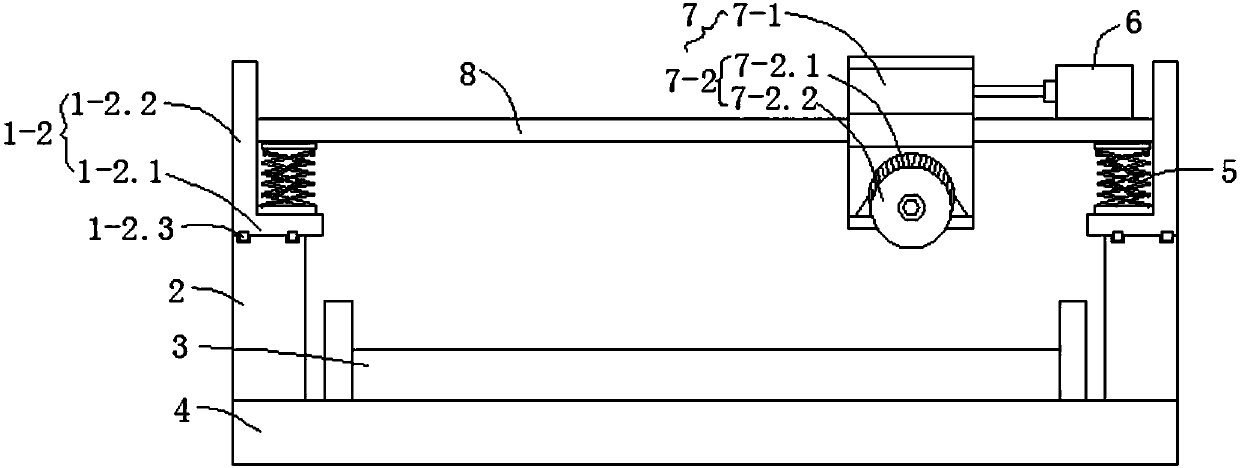

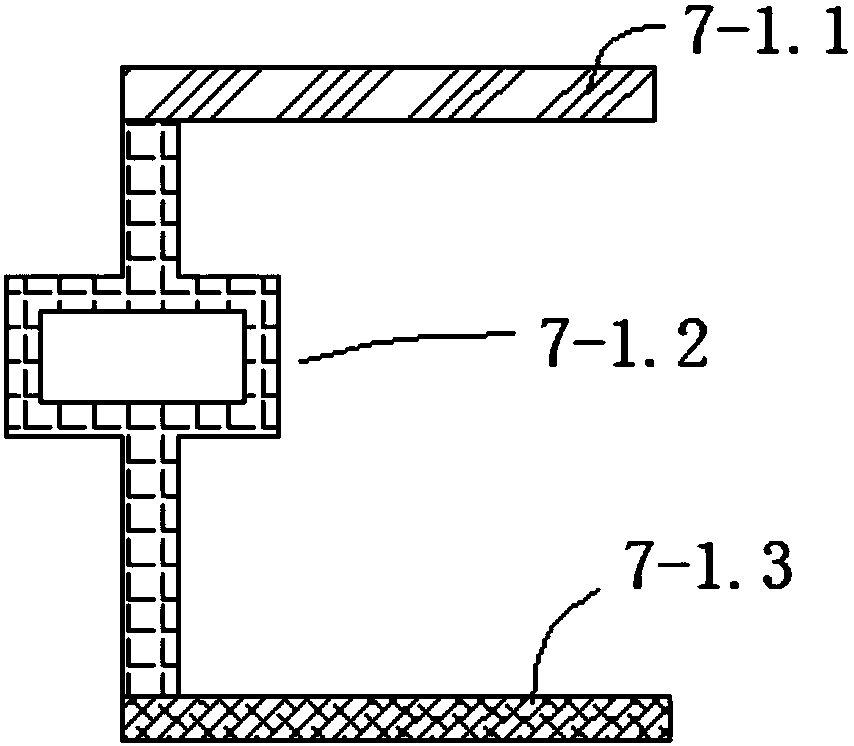

[0022] Such as Figure 1 to Figure 3 As shown, this embodiment provides a lifting and moving optical glass cutting device, including a base 4 and a cutting mechanism 7, the base 4 is provided with a fixed cutting seat 3, and the base 4 is located on both sides of the fixed cutting seat 3. The receiving plate 2 is provided with a moving mechanism 1 with the same structure respectively on the two receiving plates 2. The moving mechanism 1 includes a driving cylinder 1-1 arranged on the top side of the receiving plate 2 and a L fixedly connected with the piston rod of the driving cylinder 1-1. shaped mounting plate 1-2, the bottom of the L-shaped mounting plate 1-2 is provided with a pulley block 1-2.3, and the two receiving plates 2 are respectively provided with guide rails adapted to the pulley block 1-2.3, and the L-shaped mounting plate 1-2 includes a horizontal 1-2.1 and the vertical part 1-2.2, the horizontal part 1-2.1 is provided with a scissor lift mechanism 5, a horizo...

Embodiment 2

[0024] Such as Figure 6 As shown, this embodiment is further optimized on the basis of Embodiment 1, specifically: the scissor lift mechanism 5 includes a scissor bracket 5-1 and a plurality of hydraulic cylinders installed on the scissor bracket 5-1 5-2. The scissors support 5-1 includes a plurality of X-shaped scissors connected end-to-end from top to bottom, two adjacent X-shaped scissors are connected by hinges, and the central points of the X-shaped scissors are connected by a hinge mechanism.

Embodiment 3

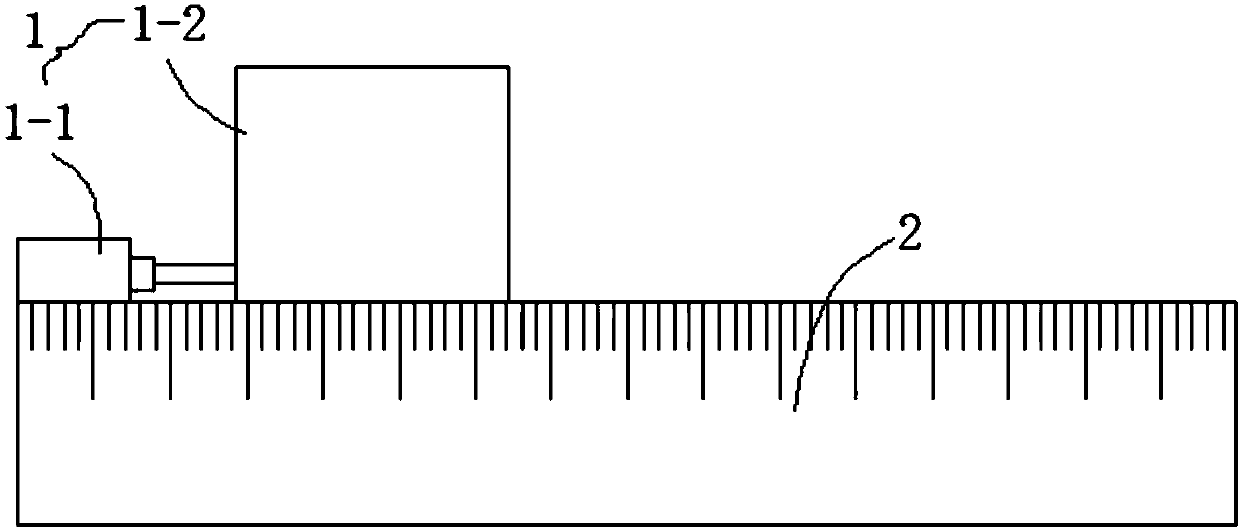

[0026] Such as figure 2 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically: the side of the receiving plate 2 away from the fixed cutting seat 3 is evenly distributed with scales along the telescopic direction of the piston rod of the driving cylinder 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com