Continuous casting cutting slag cleaning method and slag cleaning device thereof

A technology for cutting direction and slag removal, which is applied in the field of continuous casting cutting slag removal method and its slag removal device, can solve the problems of increasing cutting gas consumption, affecting cutting speed, and high cutting loss, so as to improve cutting speed and quality, cutting gas Low consumption and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through embodiment now in conjunction with accompanying drawing.

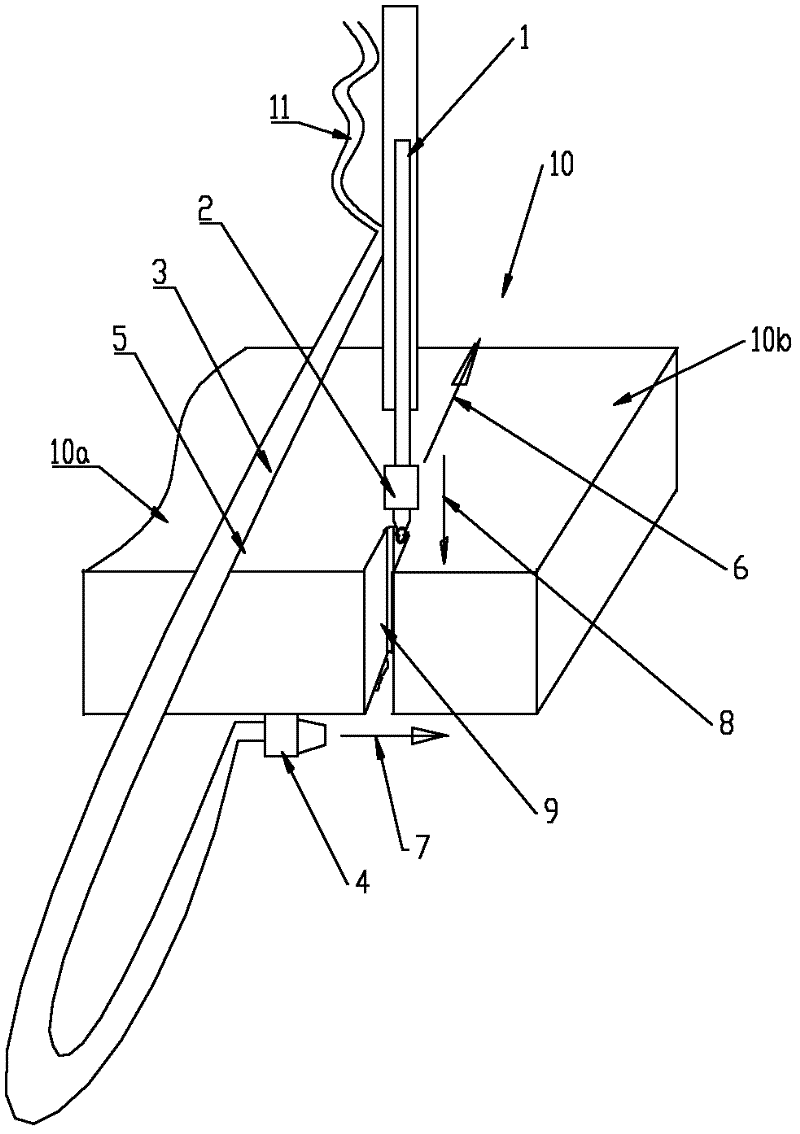

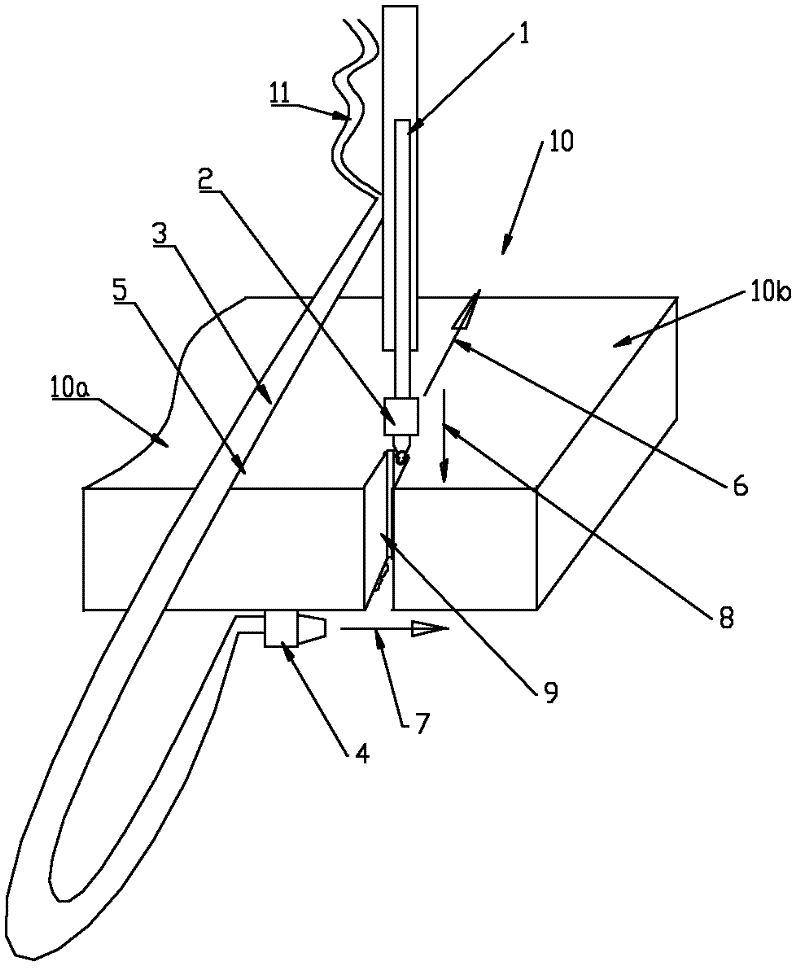

[0015] The slag removal method of the present invention is that the blowing nozzle is fixedly connected to the transverse U-shaped curved arm that moves together with the cutting nozzle, and is separated from the cutting nozzle on the opposite sides of the billet; the U-shaped curved arm is correspondingly located on the cut body ( Billet) is fixed or the side of the end to be cut, and its setting direction is the same as the cutting direction, so that the cut billet will not affect the cutting nozzle, and the direction of the blowing nozzle and the direction of the cutting nozzle are respectively horizontal On the plane and the vertical plane, or on two intersecting planes respectively, the steel slag on both sides of the slit of the billet is blown off with an inert gas through the blowing nozzle.

[0016] The embodiment of the slag removal device of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com