Cutting machine and manufacturing system for fixed size sheet

A cutting machine and blade technology, which is applied in the field of hard synthetic resin sheet cutting machines, can solve problems such as elastic parts not recorded, and achieve the effects of no chip generation, short cutting time, and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

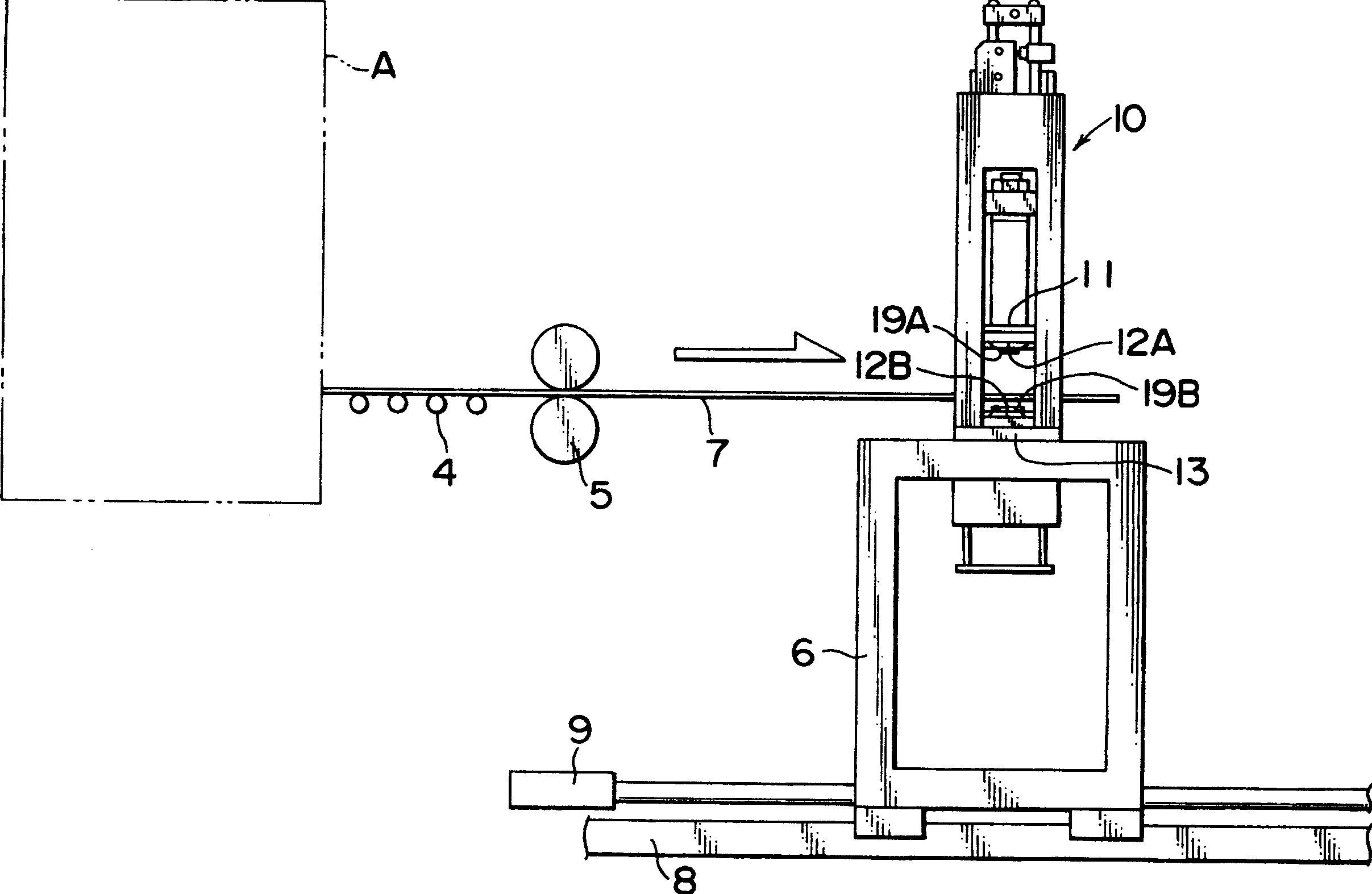

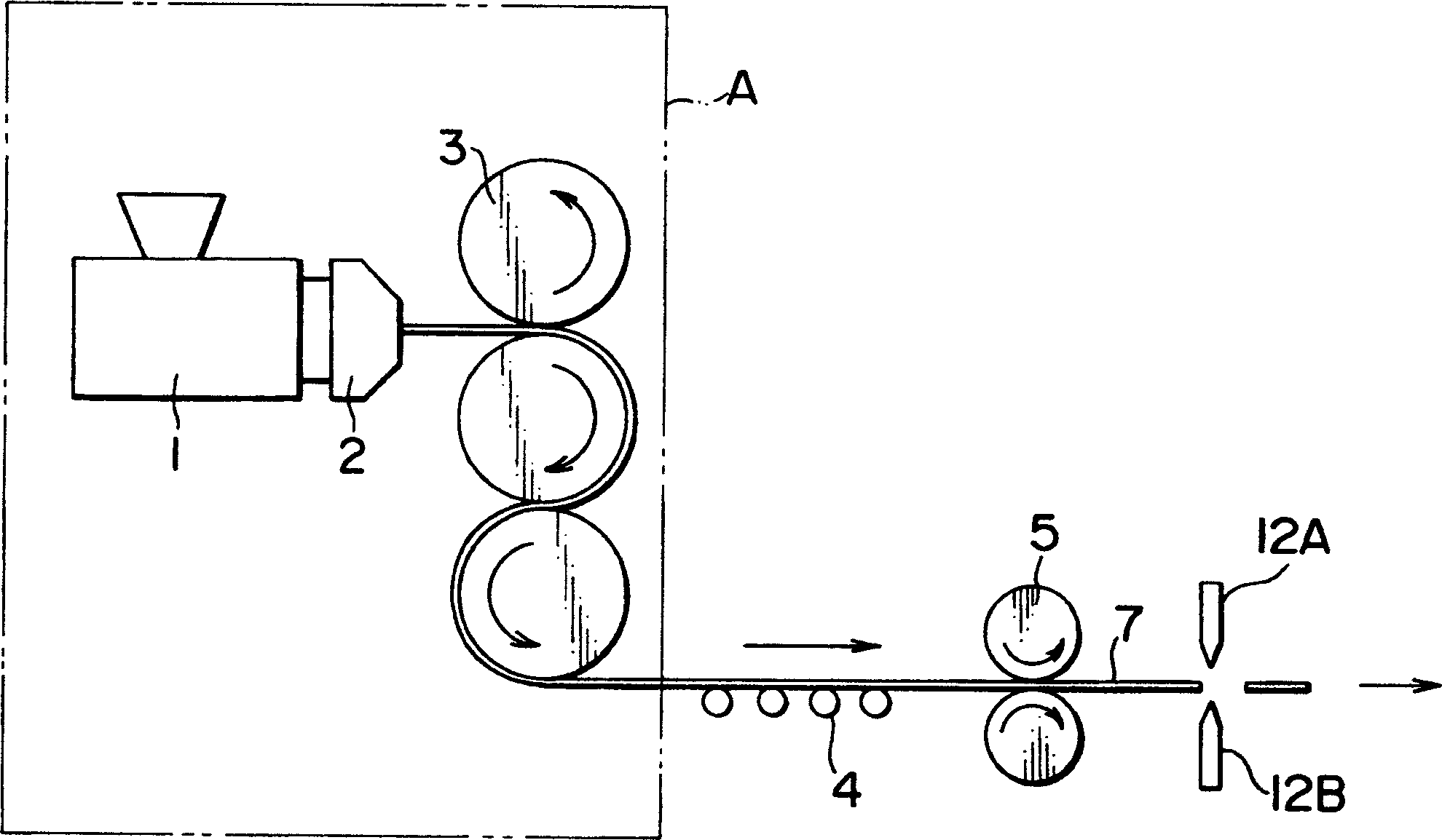

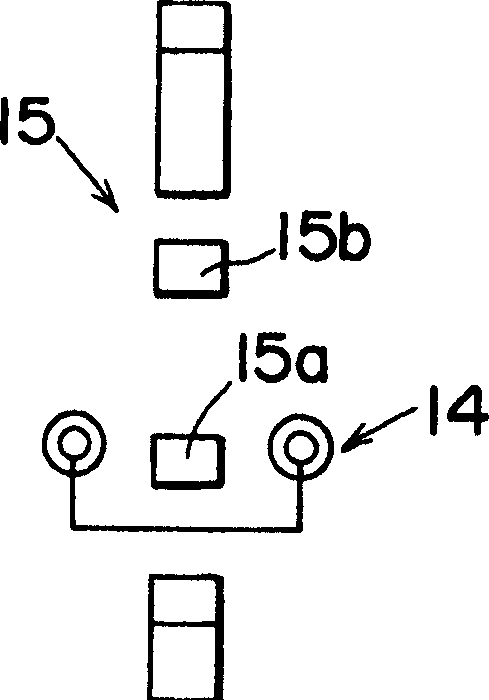

[0042] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0043] exist figure 1 and figure 2 Among them, from the left, there are extruder 1, die 2, rolling roll 3, guide roll 4, traction roll 5 and synchronous trolley 6.

[0044] The extruder 1 heats and melts a thermoplastic resin such as acrylic resin. The thermoplastic resin is heated by the extruder 1, mixed in a molten state, and continuously sent to the mold 2. The heating temperature is equal to or higher than the melting temperature of the thermoplastic resin.

[0045] The heated and melted thermoplastic resin is extruded from the die 2 into a sheet form at a speed of, for example, 10 m / min to 30 m / min. As the mold 2, for example, a normal T-die can be used. The mold 2 can extrude the thermoplastic resin in a single layer, or in a multi-layer extrusion of two layers or more than three layers. Single-layer continuous sheets can be formed by utili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com