A pipe cutting device

A cutting device and pipe technology, applied in broaching device, broaching machine, metal processing equipment and other directions, can solve the problems of equipment instability, fighting with each other, etc., and achieve the effect of compact structure, high production efficiency and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

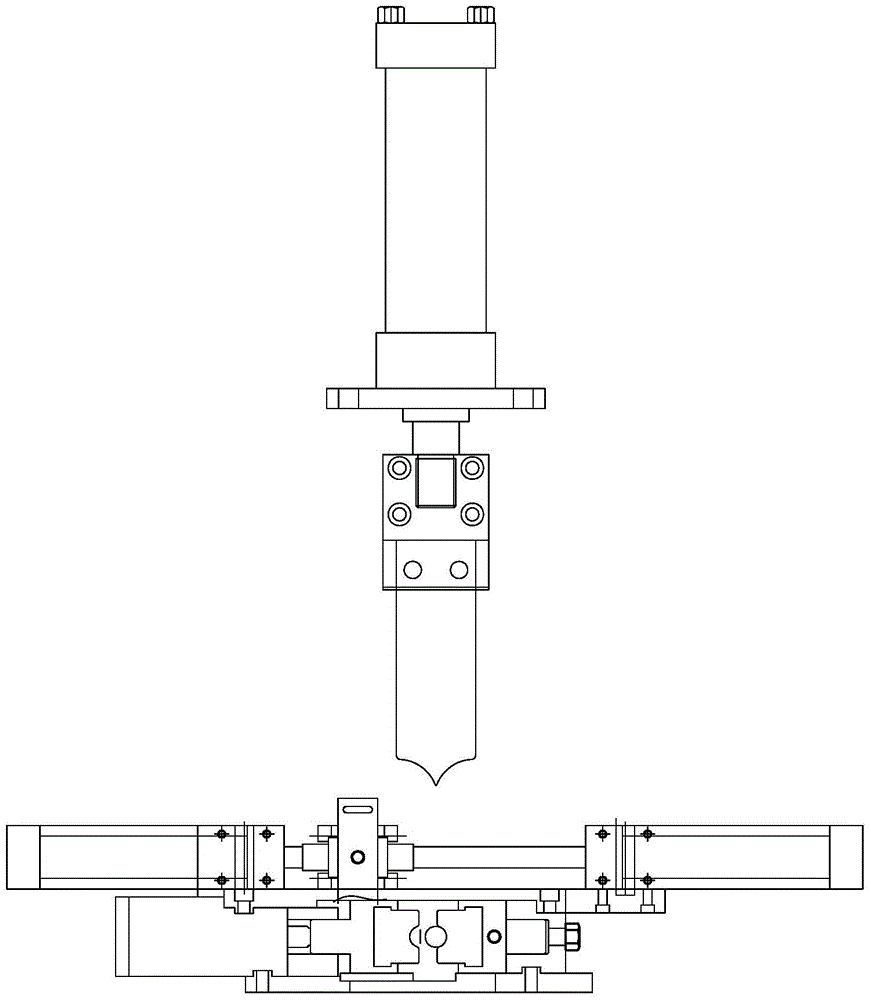

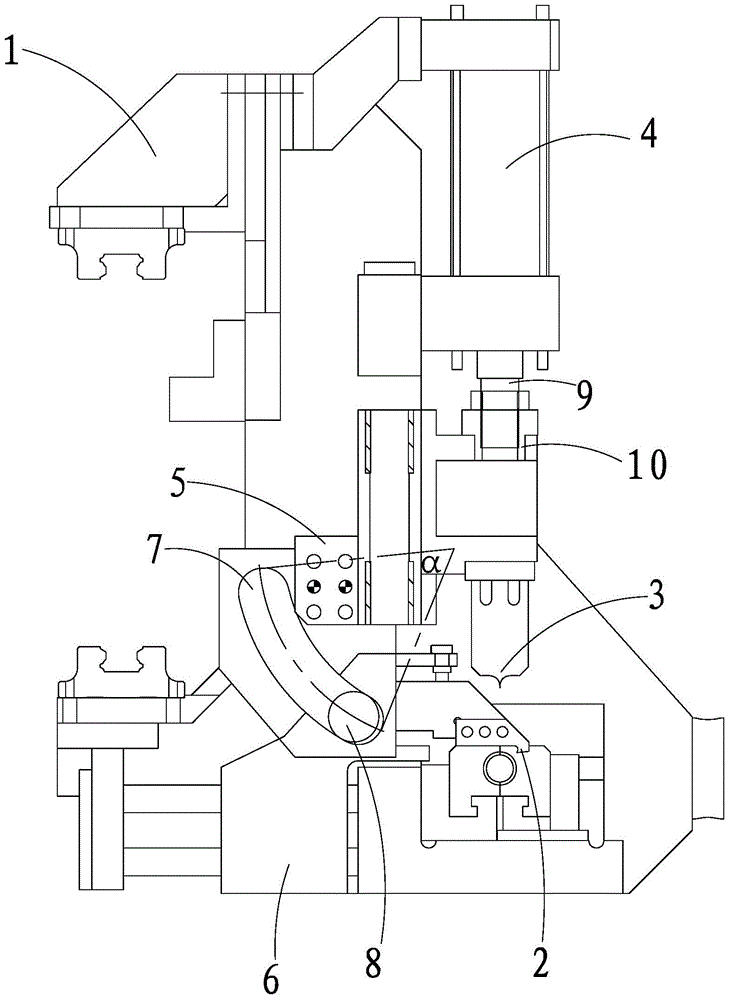

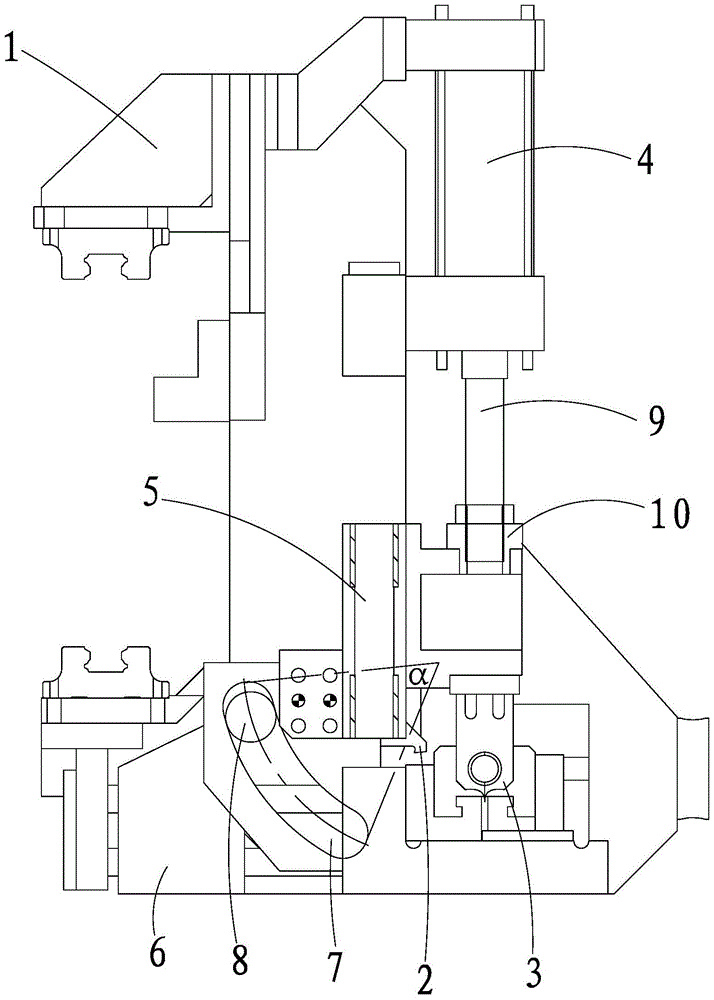

[0019] As shown in the figure, a pipe cutting device includes a frame 1 , A broach that can pull the pipe out of the gap 2 , A punching knife that can cut off the notched pipe 3 , The pipe cutting device also includes installed on the frame 1 Can drive the punch 3 A power source that moves up and down 4 , Used to power source 4 With broach 2 Drive connection so that the broach 2 A transmission mechanism that moves in the forward and backward directions. In power source 4 Driven by the drive and the transmission mechanism, in the punch 3 When moving down, the broach 2 Move backward; punch 3 When moving upward, the broach 2 Move forward; during the whole movement, the broach 2 With punch 3 not in contact.

[0020] The transmission mechanism includes the power source 4 Power source 4 Active block that drives to move up and down 5 Active block 5 Drive movement and can be slid in the front and rear directions on the frame 1 Follower block 6 , Broach 2 Installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com