Planer device for clearing part surfaces and using method of planer device

A technology of parts and planers, which is applied in the field of aero-engine manufacturing, can solve the problems of difficult control of operation accuracy, long cutting time, and low production efficiency, and achieve the effects of easy control of operation accuracy, short cutting time, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

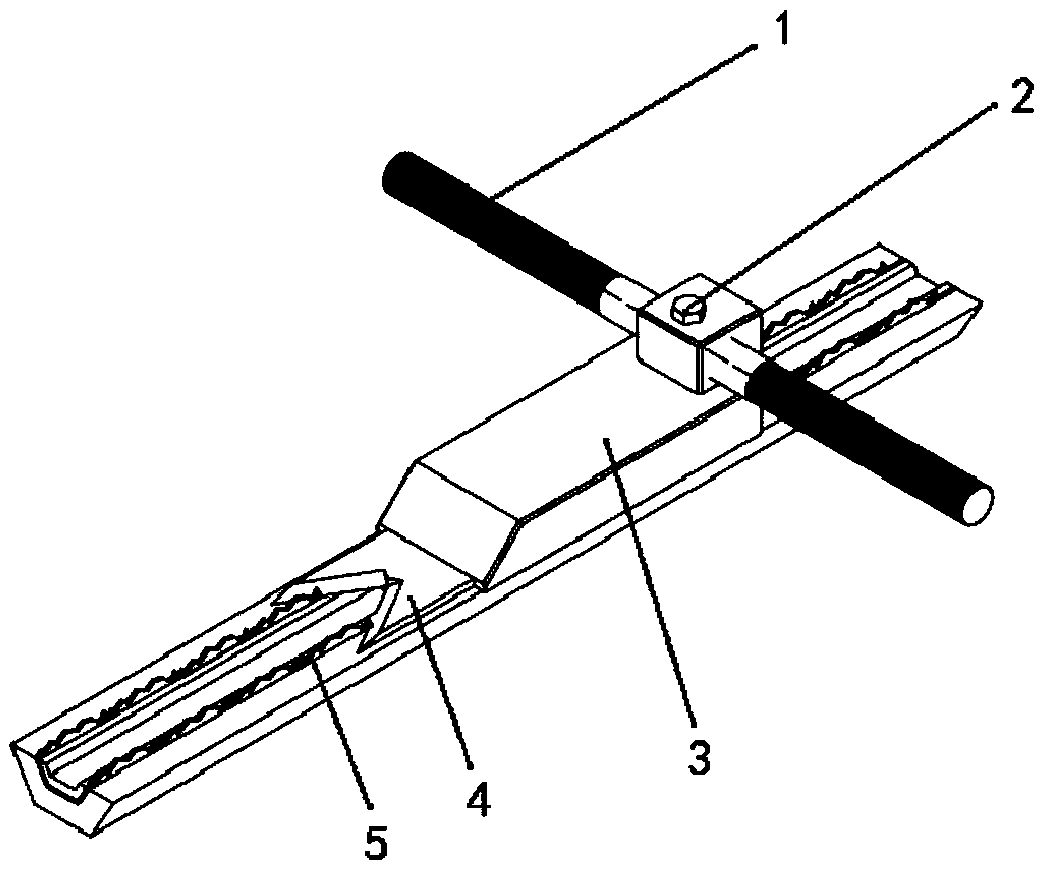

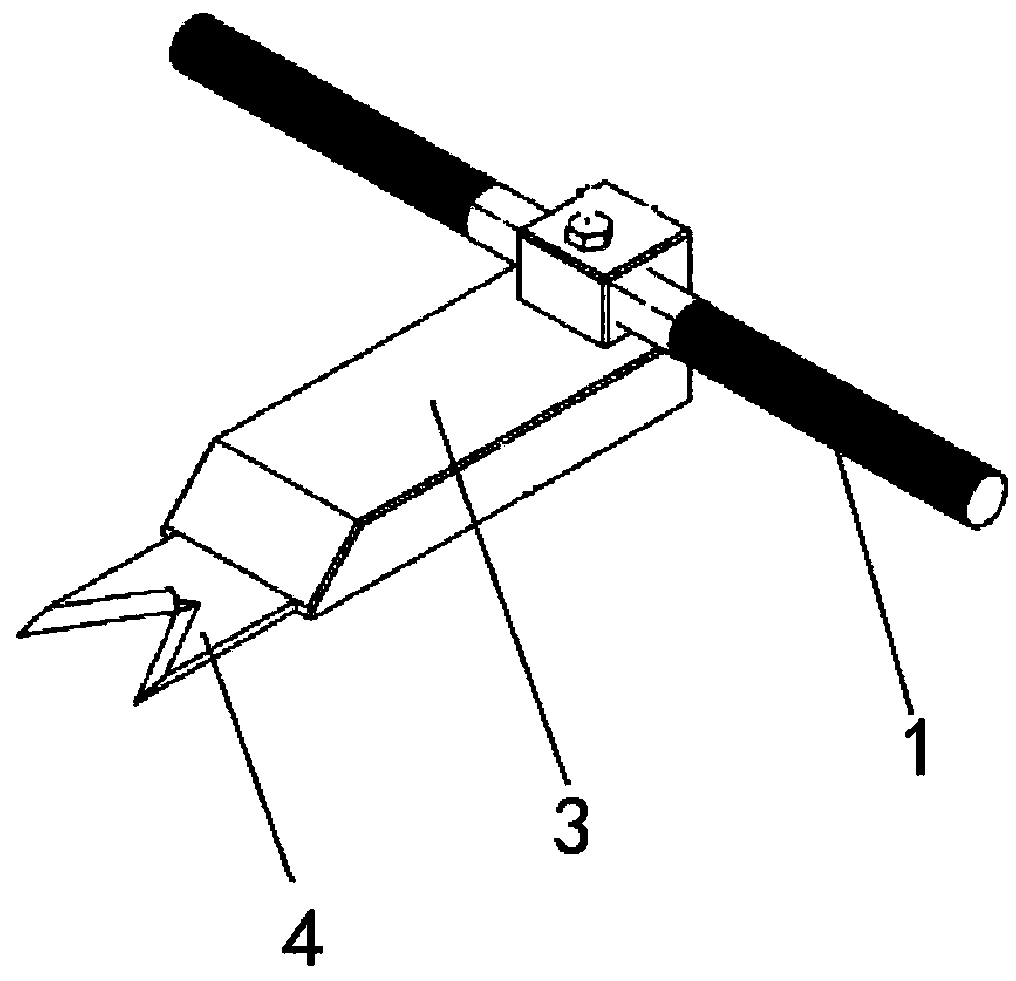

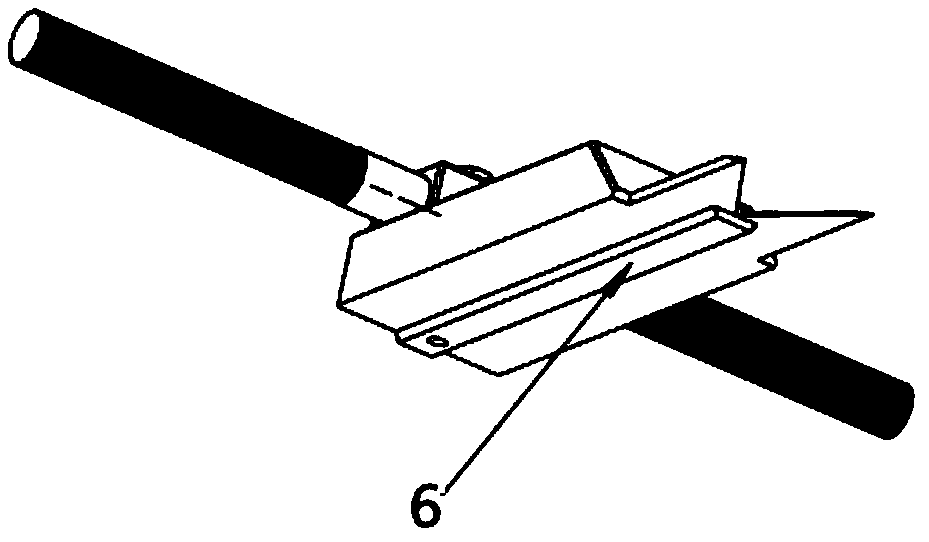

[0030] Such as Figure 1-7 As shown, the present invention provides a planer device for removing the surface of parts, including a handle 1, a connecting block 8, a base 3 and a planer 4; the handle 1 is mounted on the connecting block 8; the connecting block 8 Installed on the base 3 through the fixing member 2; the planer 4 is installed at the top position below the base 3; the base 3 is provided with a convex strip 6; the connecting block 8 is provided with a convex block 7 and a concave Hole A9, and there is a gap between the two; the base 3 is provided with a square groove 11 and a concave hole B10, and there is a gap between the two; the convex block 7 is connected with the square groove 11; the concave hole The positions of A9 and the concave hole B10 correspond to the same.

[0031] The fixing member 2 is fixed by bolts.

[0032] A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com