Circular tool for cutting material

A technology for cutting materials and tools, which is used in the manufacture of tools, tools for sawing machines, and tool manufacturing for sawing machines. The effect of short durability and reduced cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

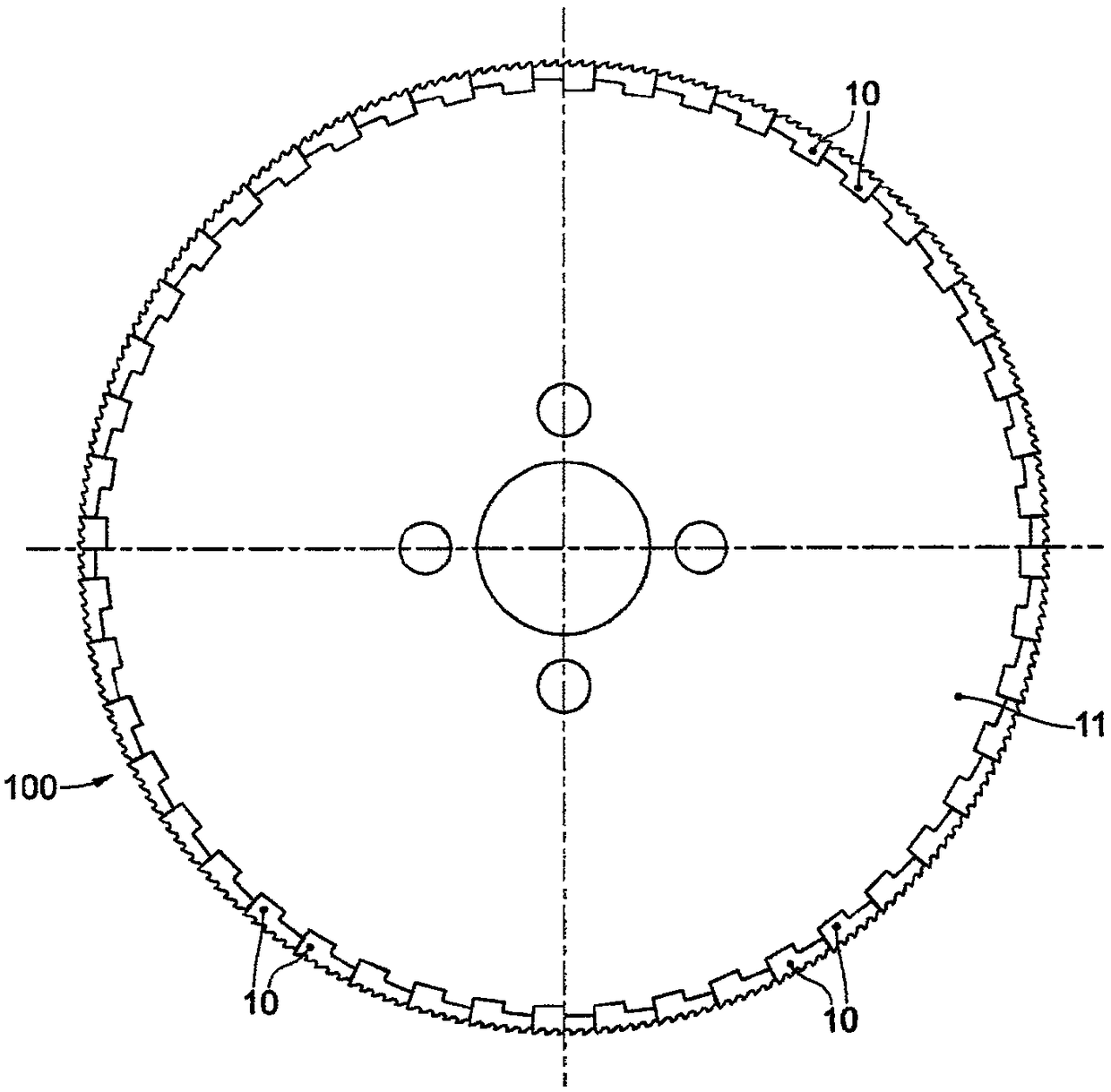

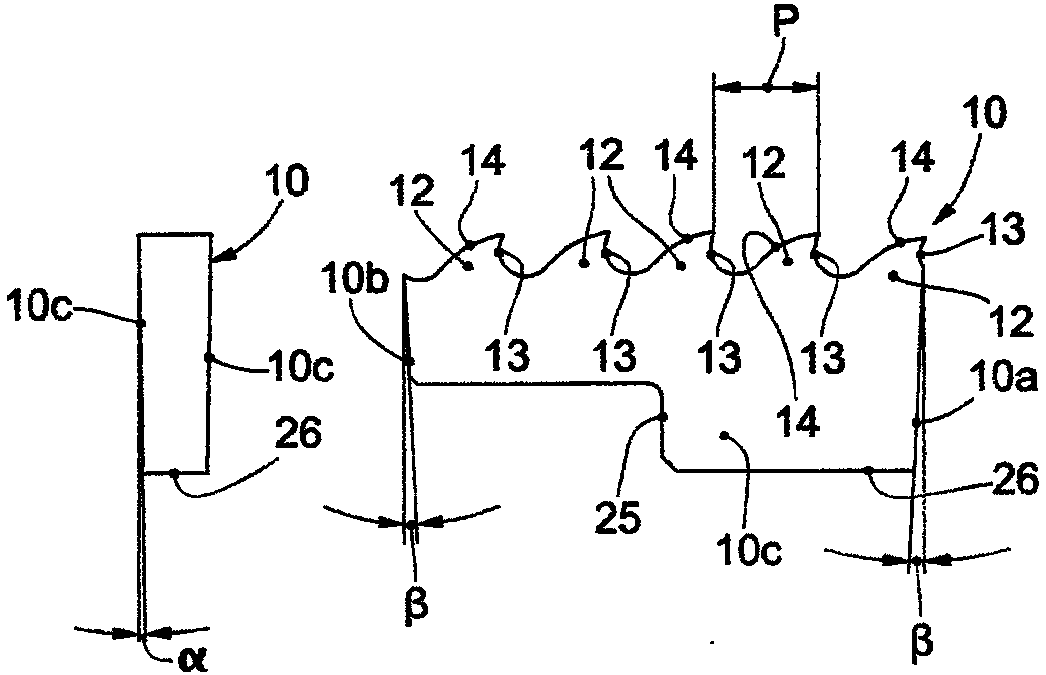

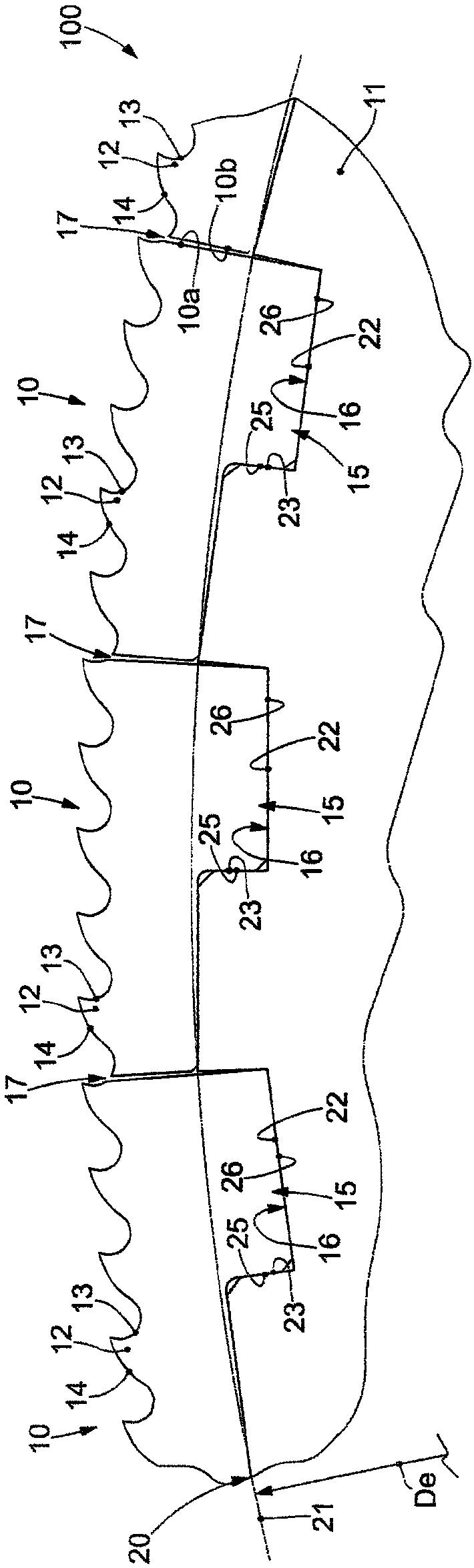

[0057] According to the present description and with reference to the accompanying drawings, the present invention relates to a circular tool 100 for cutting metallic material such as low or high alloy steel, titanium, aluminum or the like.

[0058] Furthermore, the tool 100 is particularly suitable for cutting small workpieces with reduced thickness.

[0059] For example, the tool 100 can cut solid rods with diameters between 5 mm and 120 mm, pipes with dimensions smaller than 5 mm and larger than 600 mm and thicknesses between 0.4 mm and 25 mm, or through Parallelepiped workpieces obtained by forming round tubes. Furthermore, the tool 100 may be adapted to a particular machine, such as an orbital machine, in which the same tool 100 is made to rotate around a workpiece in order to cut larger sized workpieces.

[0060] The tool 100 comprises a support disc 11 and a plurality of cutting inserts 10 attached to the circumferential periphery of the support disc 11 .

[0061] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com