Cutting device for solar panel for environment-friendly power station

A technology for solar panels and cutting devices, which is applied to grinding drive devices, grinding/polishing safety devices, and manufacturing tools, etc., can solve the problems of unfriendly cutting, uneven cutting surface, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

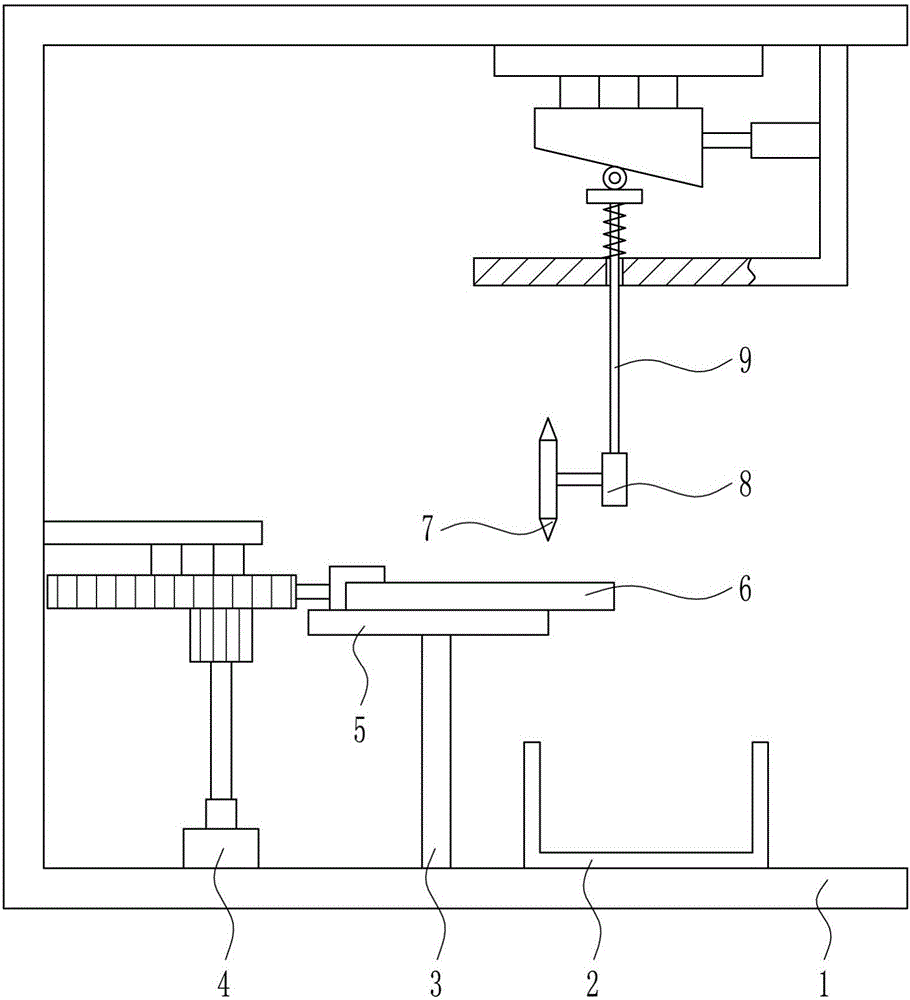

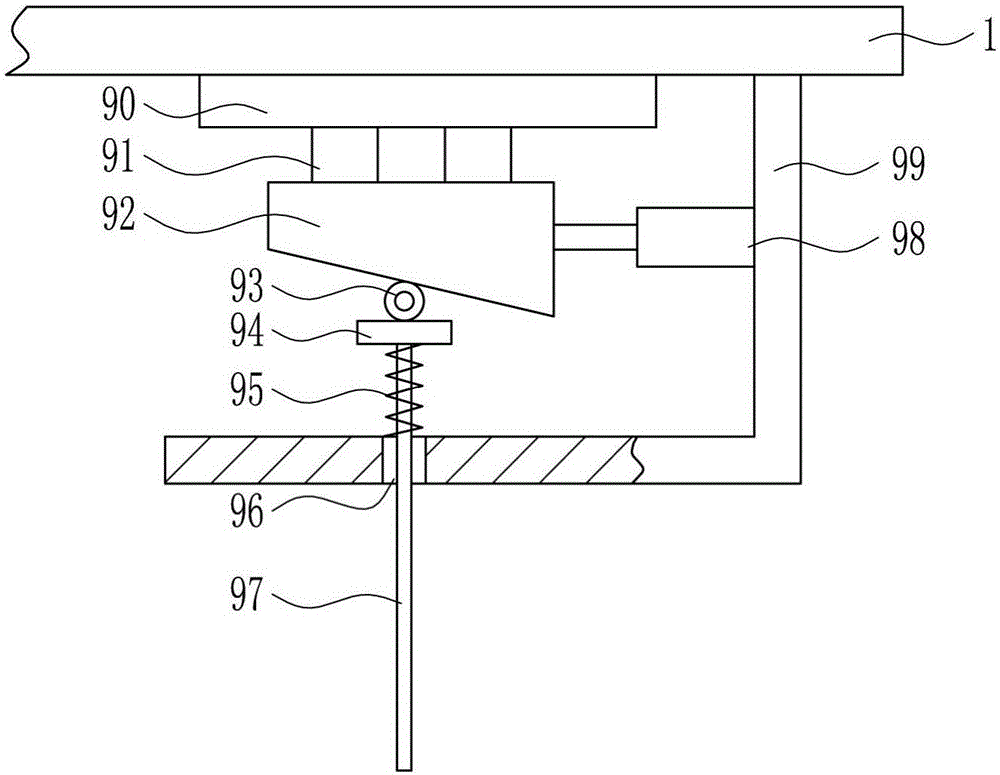

[0042] An environment-friendly solar panel cutting device for power stations, such as Figure 1-9 As shown, it includes a bracket 1, a collection frame 2, a pole 3, a pushing device 4, a placement plate 5, a grinding wheel 7, a second motor 8 and a lifting device 9; the bottom of the bracket 1 is sequentially provided with a pushing device 4 from left to right , pole 3 and collection frame 2, the top of pole 3 is provided with a placement plate 5, the top right side of the support 1 is provided with a lifting device 9, the bottom of the lifting device 9 is provided with a second motor 8, and the left end of the second motor 8 is connected with a grinding wheel 7.

Embodiment 2

[0044] An environment-friendly solar panel cutting device for power stations, such as Figure 1-9 As shown, it includes a bracket 1, a collection frame 2, a pole 3, a pushing device 4, a placement plate 5, a grinding wheel 7, a second motor 8 and a lifting device 9; the bottom of the bracket 1 is sequentially provided with a pushing device 4 from left to right , pole 3 and collection frame 2, the top of pole 3 is provided with a placement plate 5, the top right side of the support 1 is provided with a lifting device 9, the bottom of the lifting device 9 is provided with a second motor 8, and the left end of the second motor 8 is connected with a grinding wheel 7.

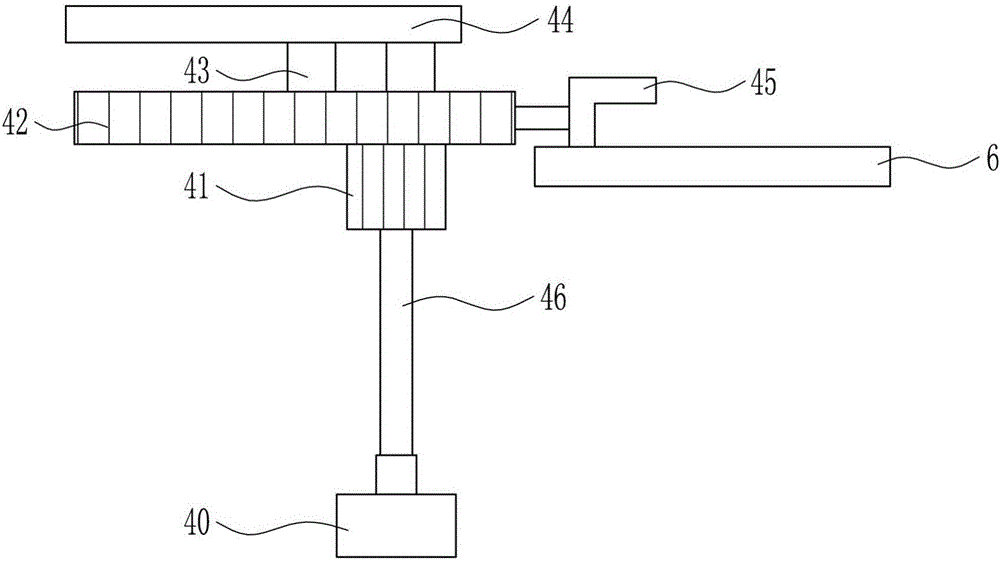

[0045] Propelling device 4 comprises first motor 40, gear 41, rack 42, first slide block 43, first slide rail 44, push block 45 and rotating shaft 46, and support 1 inner bottom is provided with first motor 40, and first motor 40 is positioned at the left side of pole 3, and first motor 40 is provided with rotating...

Embodiment 3

[0047] An environment-friendly solar panel cutting device for power stations, such as Figure 1-9 As shown, it includes a bracket 1, a collection frame 2, a pole 3, a pushing device 4, a placement plate 5, a grinding wheel 7, a second motor 8 and a lifting device 9; the bottom of the bracket 1 is sequentially provided with a pushing device 4 from left to right , pole 3 and collection frame 2, the top of pole 3 is provided with a placement plate 5, the top right side of the support 1 is provided with a lifting device 9, the bottom of the lifting device 9 is provided with a second motor 8, and the left end of the second motor 8 is connected with a grinding wheel 7.

[0048] Propelling device 4 comprises first motor 40, gear 41, rack 42, first slide block 43, first slide rail 44, push block 45 and rotating shaft 46, and support 1 inner bottom is provided with first motor 40, and first motor 40 is positioned at the left side of pole 3, and first motor 40 is provided with rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com