Ultrathin stone turning-free plate type flow line stone sawing machine and ultrathin stone cutting method

A flap-type, assembly-line technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of cumbersome operation and low work efficiency, and achieve the effect of smooth cutting surface and good cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

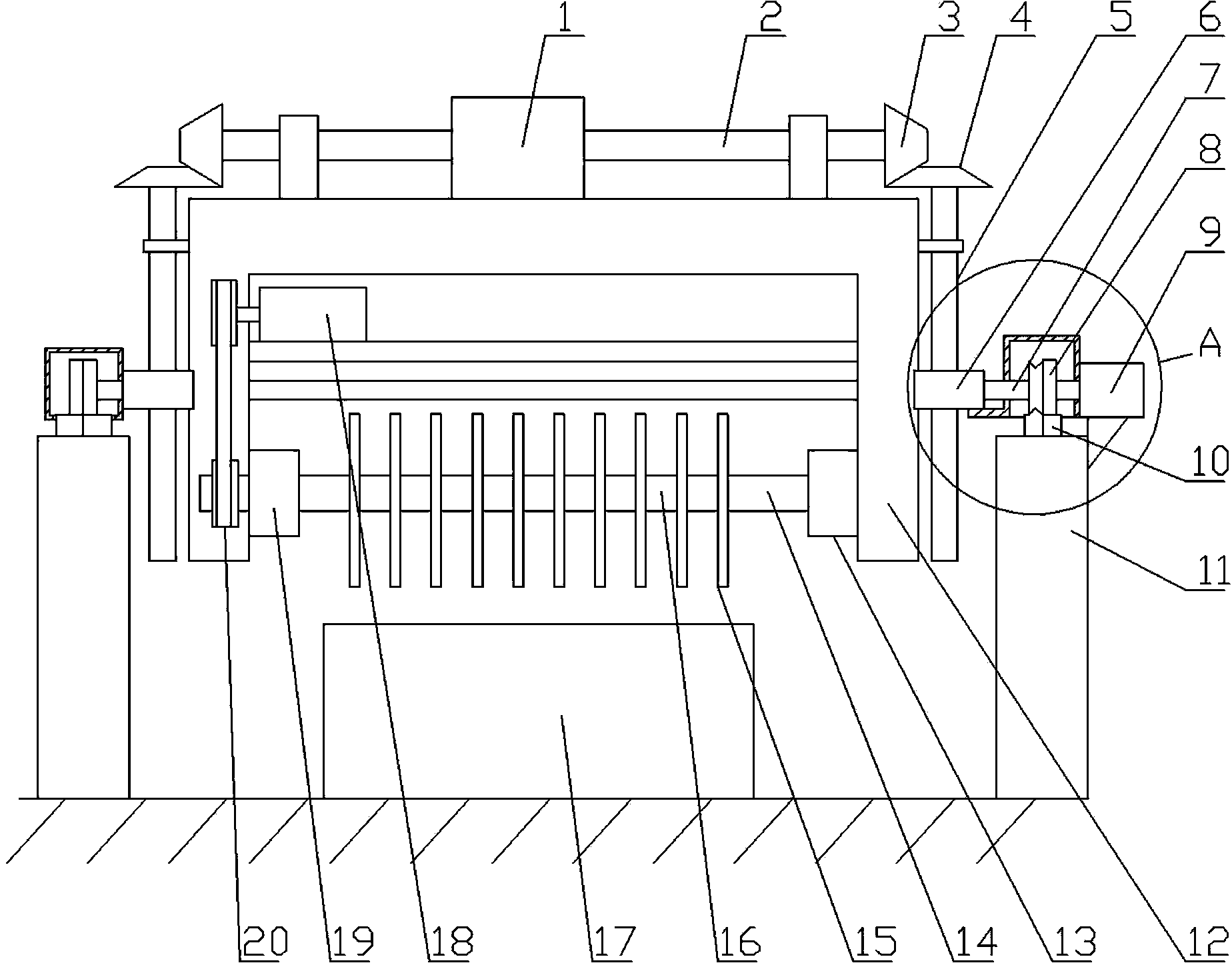

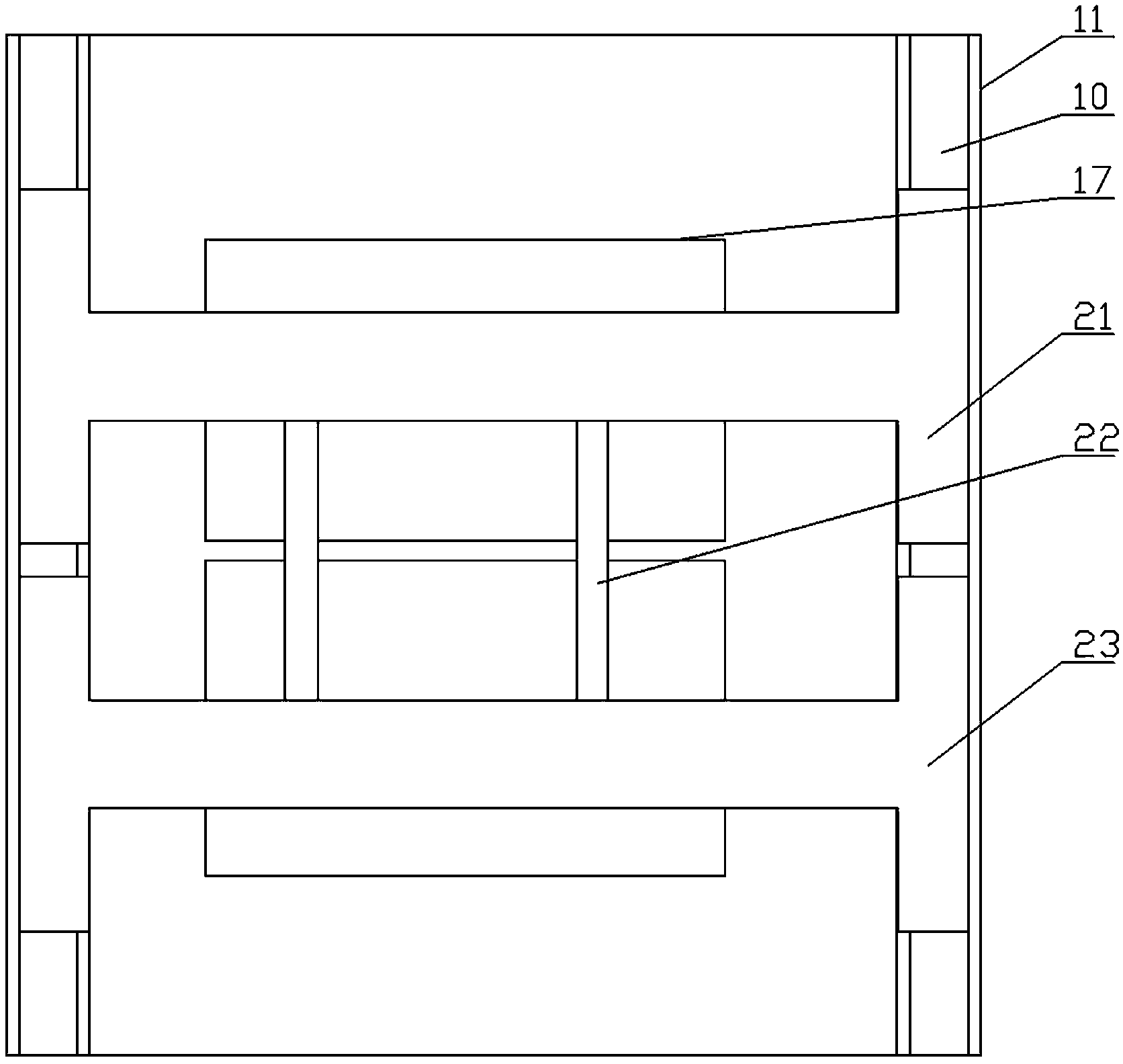

[0020] like figure 1 and figure 2 A specific embodiment is shown, which includes two parallel horizontal guide rails, a cutting main machine I21, a cutting main machine II23 and a material rack 17. The cutting host I21 and the cutting host II23 are connected through the connecting frame 22 . The two cutting mainframes are erected on the two guide rails, and the material rack 17 is arranged between the two guiding rails and is located below the two cutting mainframes.

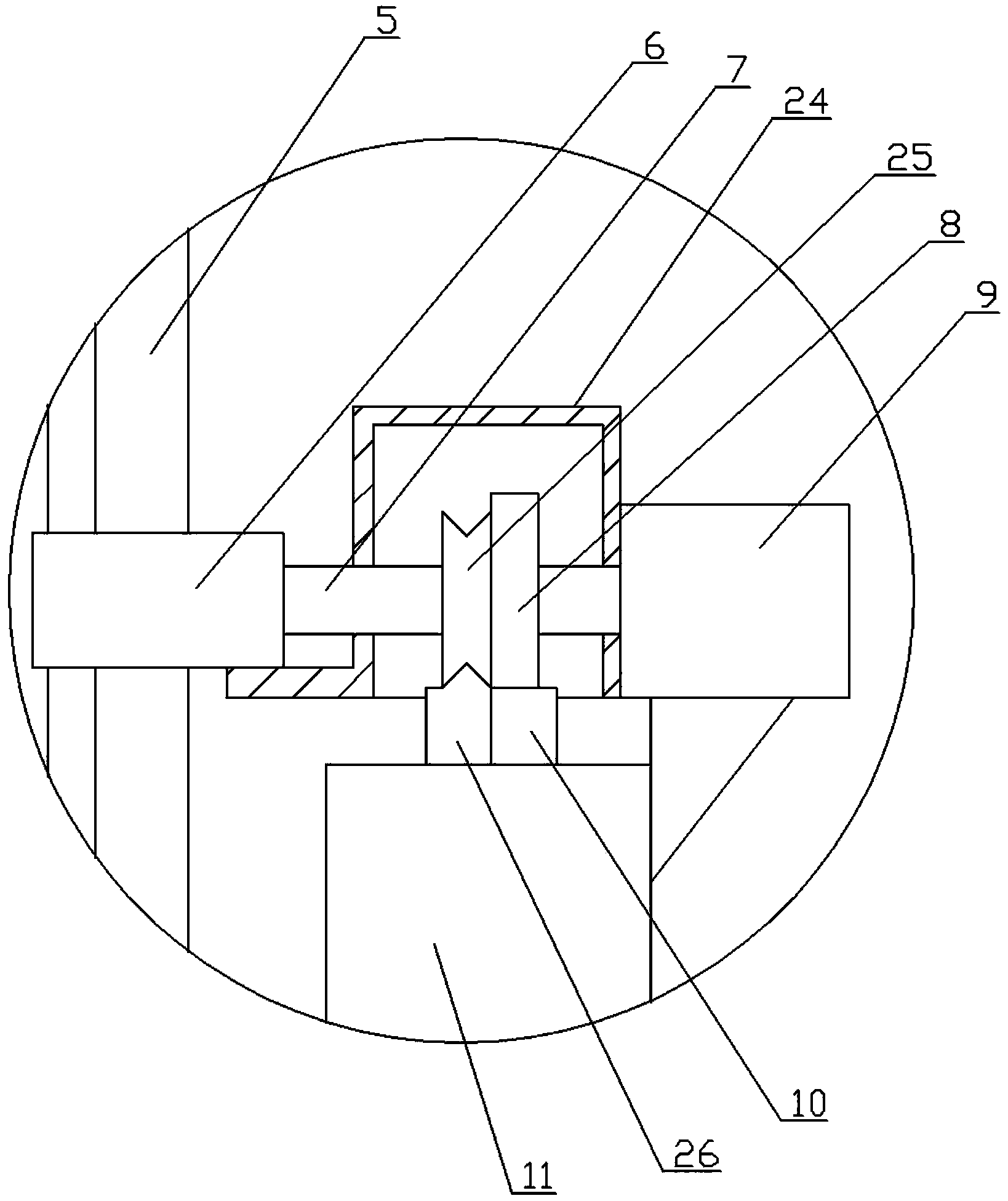

[0021] like figure 1 , figure 2 and image 3 As shown, the cutting main machine includes a translation frame 24, a gantry frame 12, a main shaft 14 and a saw blade 15. There are two translation frames 24, and the two translation frames 24 are slidably arranged on two guide rails, respectively. A transmission shaft II7 is arranged between the translation frames 24, each guide rail is fixed on a base 11, and the two guide rails both include a horizontal sliding guide rail 26 and a horizontal gear rack 10. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com