Coalescence degreaser for oilfield sewage treatment

A coalescing degreaser and oilfield sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problem of ineffective implementation of anti-corrosion methods, corrosion of equipment body and internal components , stable operation, adverse effects and other issues, to ensure long-term safe and effective operation, improve sewage treatment capacity, and excellent mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

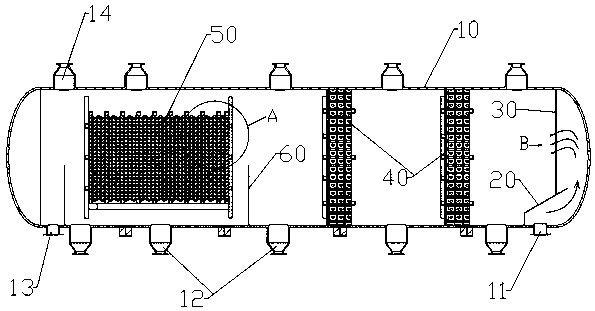

[0066] Such as figure 1 As shown, a coalescence degreaser for oilfield sewage treatment provided in this embodiment includes: a tank body 10; inside the tank body 10, a flow stabilization device 20, a rectification device 30, a primary filtration Device 40 and oil gathering device 50. The bottom of the right end of the tank body 10 is provided with a medium inlet 11, the top of the tank body 10 is provided with one or several oil collecting ports 14, and the bottom of the other end of the tank body 10 is provided with a drain port 13; the bottom of the tank body 10 Several mud outlets 12 are arranged at intermediate intervals. Several fenders 60 are also arranged at intervals in the tank body 10 to prevent the silt from continuing to flow. Generally, the fenders 60 are arranged on one side of the downstream direction of the water flow at the mud discharge port 12, thereby guiding the silt through the discharge. Mud discharge.

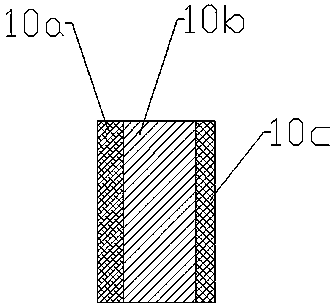

[0067] Such as figure 2 As shown, the tank b...

Embodiment 2

[0082] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

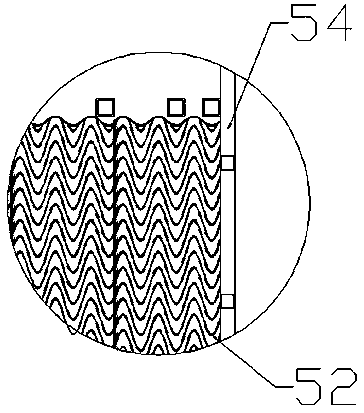

[0083] Such as Figure 7 As shown, the oil gathering device provided in this embodiment includes: a coalescing and separating corrugated plate 52 and a support member 51; a plurality of the coalescing and separating corrugated plates 52 are arranged at intervals up and down, and two adjacent coalescing and separating corrugated plates A wave-shaped water flow channel 53 is formed between 52; the support member 51 is erected in the water flow channel 53, and its two ends are fixedly connected with two adjacent coalescing and separating corrugated plates 52 up and down.

[0084] The present invention increases the cross-sectional area of the water flow channel 53 between adjacent corrugated plates by thinning the thickness of the corrugated plates in the prior art, thereby greatly improving the sewage treatment capacity; and under the premise that the sewage treatment...

Embodiment 3

[0095] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that:

[0096] Such as Figure 10 As shown, when the coalescing and separating corrugated plate 52 is relatively thin, for example, when the thickness is less than 5mm, the easier way to arrange the support member 51 is: the top and bottom of the coalescing and separating corrugated plate 52 are respectively provided with installation protrusions and insertion groove, the installation protrusion and the insertion groove can be formed synchronously when the coalescing and separation corrugated plate 52 is laminated; the support member 51 is a truncated cone, and the bottom of the support member 51 is set to be inserted into the installation protrusion The connection hole, the top of the support member 51 is provided with a clip joint inserted into the insertion slot.

[0097] The supporting member 51 is generally in the shape of a truncated cone. When the sewage flows thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com