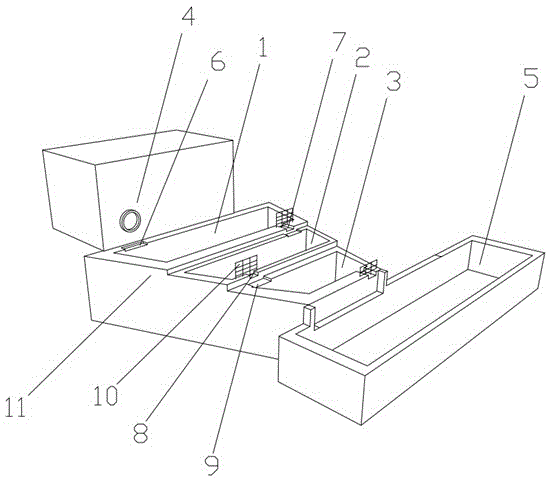

Sedimentation tank for paint spraying wastewater treatment

A technology for wastewater treatment and treatment pool, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can save the processing time, simplify the wastewater treatment process, and be beneficial to the popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

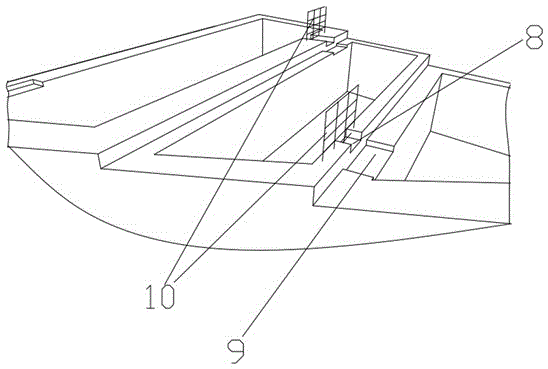

[0028] The painting wastewater flows out from the painting process 4 to the first-stage treatment pool 1, and is in a static or slow flow state in the pool. The slag blocks with a specific gravity smaller than water in the waste water float to the water surface, and the slag blocks with a specific gravity larger than water sink to the bottom of the pool. With the injection of waste water, when the liquid level reaches the drain 7 of the first-stage treatment tank 1, since the bottom of the water inlet 6 of each treatment tank is higher than the bottom of the drain 7 of the treatment tank, the waste water overflows from the drain 7 , flow through the second treatment pool 2 and the third treatment pool 3 in sequence, continue to separate in the second treatment pool 2 and the third treatment pool 3, and finally flow from the drain of the third treatment pool 3 to the external wastewater treatment process, The slag blocks floating on the water surface are blocked by the filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com