Microfabricated diffusion-based chemical sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Fabrication of Channel Cell

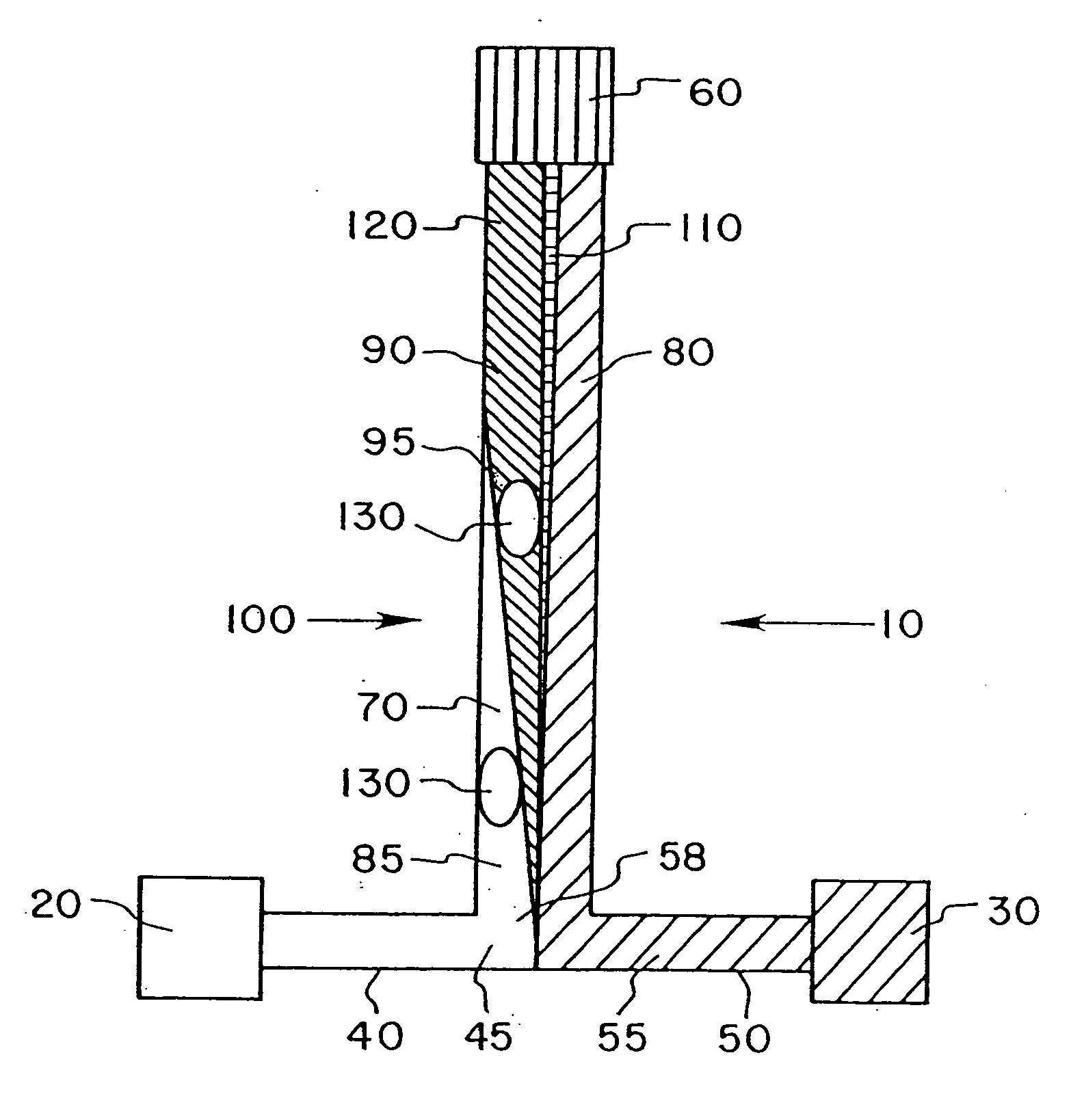

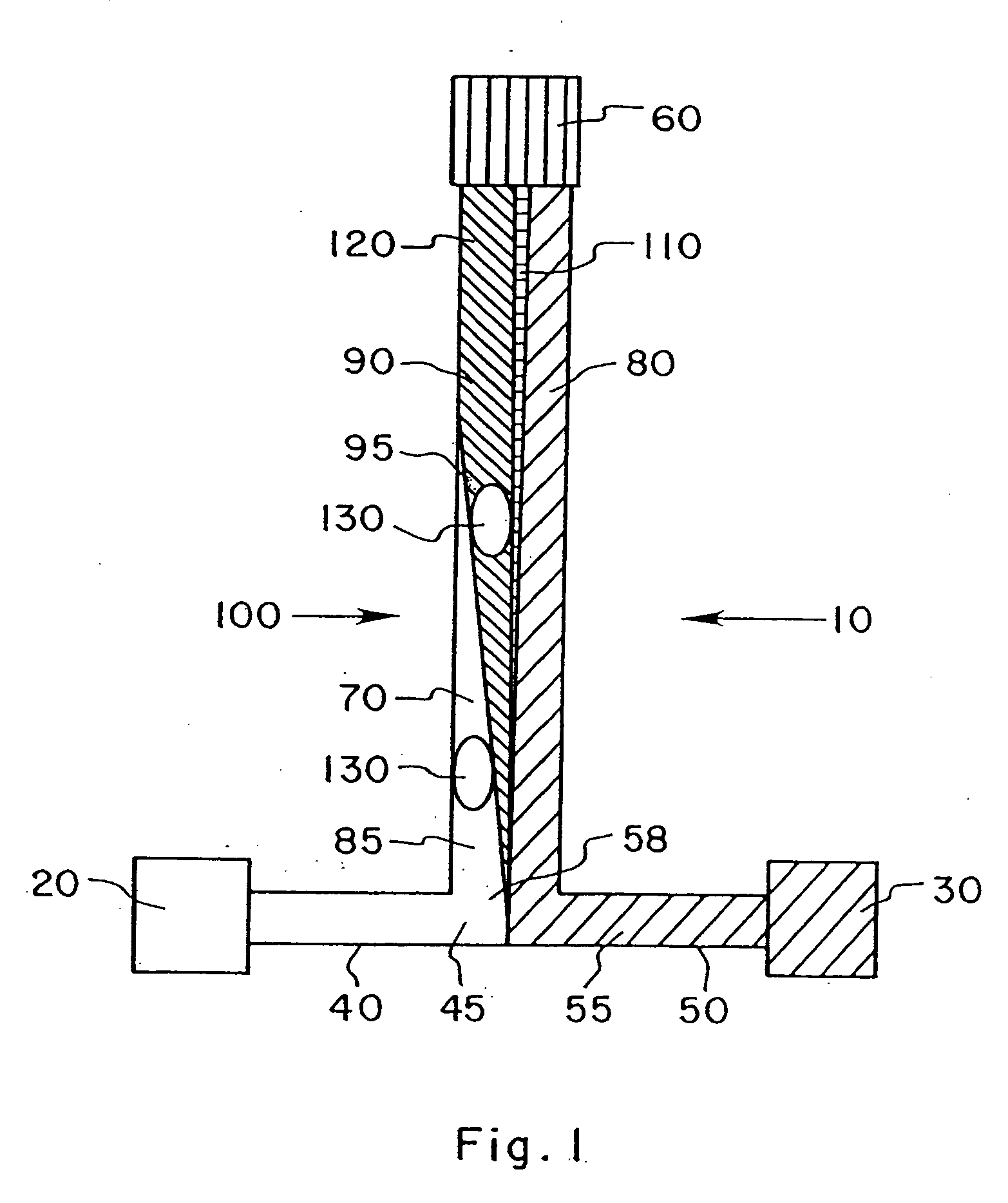

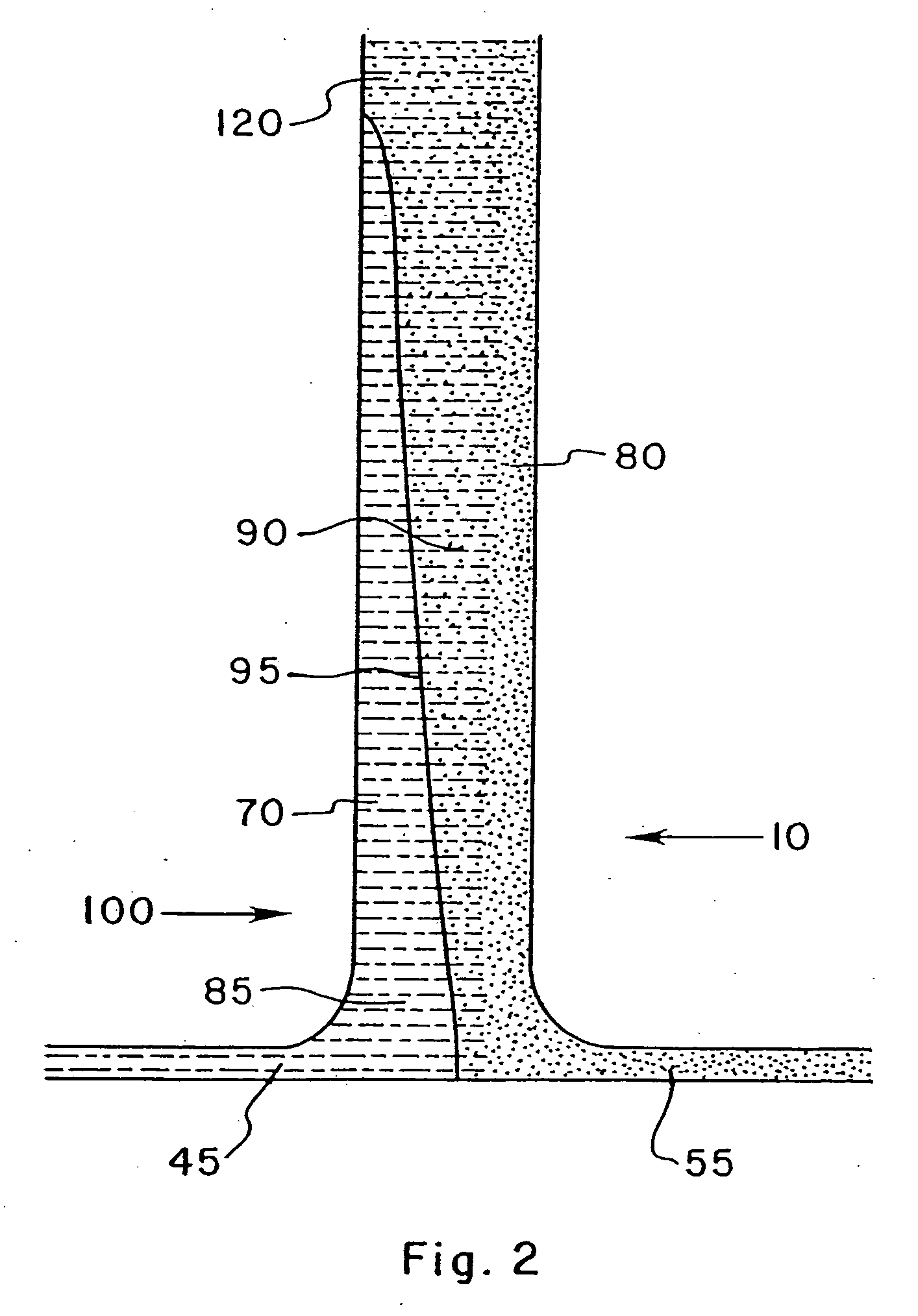

[0130] A two-mask level process was used to fabricate a channel cell of this invention on a silicon wafer. The channel cell had a flow channel 400 micrometers wide and 20 mm long. The “branches” or crossbar of the “T” comprising the inlet channels was a groove 30 mm long and 200 micrometers wide. Channel depth was 50 micrometers.

[0131] The first mask level defined the inlets and outlet ports, which were etched completely through the wafer to the rear side of the silicon. The second level defined the fluid transport channels.

[0132] Four inch chrome masks were made to these specifications by Photo Sciences, Inc. (Torrance, Calif.) and 3″ wafers ({100}, n-type) with 500 nm of SiO2 grown on them were used.

[0133] Wafers were cleaned in a Piranha bath (H2SO4 and H2O2) (2:1) before processing. A primer (HMDS spun on at 3000 rpm) was used to enhance photoresist adhesion. About one μm of AZ-1370-SF (Hoechst) photoresist was deposited by spin coating (3000 rpm),...

example 2

Fluorescence Color Changes with pH

[0139] Five 0.01 M HEPES Buffer solutions, with pH 7.2, 7.4, 7.6, 7.8 and 8.0 were prepared from analytical grade chemicals (Aldrich). The resulting solutions were used consecutively as sample streams. The analyte in question in this experiment is H+ or OH−. 1 mg of the fluorescent pH indicator dye carboxy-SNAFL 2 (Molecular Probes, Eugene, Oreg.), was dissolved in 2 ml of DMSO (((0.9%, Aldrich). 0.1 ml of this solution was mixed with 1 ml of a 0.0001 M HEPES Buffer of pH 7.0. The resulting solution was used as the indicator stream.

[0140] The T-sensor channel cell was attached to the stage of a microscope so that the joint of the T-sensor was in the view field of the objective. The inlet ports and the outlet port were connected to injector loops and to upright tubes which were filled with water so that there was a pressure difference of 30 mm water column between the inlet ports and the outlet port. Both inlet ports were exposed to identical press...

example 3

Kinetic Measurements as a Function of Distance

[0143] Alkaline phosphatase in serum and 0.1 M p-nitrophenol phosphate (PNPP)(weakly yellow) in 0.1 M HEPES buffer, pH 7.40, were injected into a T-sensor device. The alkaline phosphatase catalyzed the reaction of PNPP to p-nitrophenol (strongly yellow) and phosphate. The formation, (and rate thereof), of p-nitrophenol was detected by an increase in yellow color. The rate of change of yellow color intensity as a function of distance from the T-joint was a function of enzyme concentration, enabling calculation of a rate constant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com