Urea heating device for efficient SCR, and use method thereof

A technology of heating device and urea, which is applied in the direction of muffler device, exhaust device, electric control of exhaust gas treatment device, etc. The effect of sufficient solution, avoiding urea crystallization and reducing the risk of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

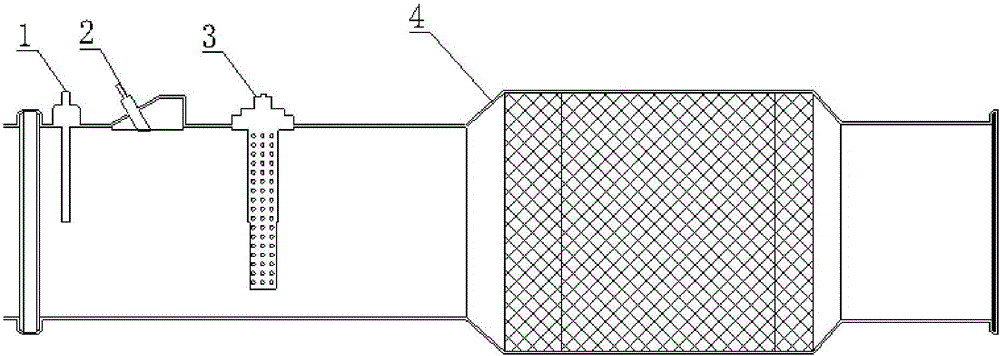

[0033] A urea heating device for high-efficiency SCR, including temperature sensor 1, urea nozzle 2, metal carrier catalyst 3 and SCR4; temperature sensor 1, urea nozzle 2, metal carrier catalyst 3 are placed in front of SCR4, and the three are sequentially from front to back set on the exhaust pipe;

[0034] Temperature sensor 1, which transmits the identified temperature signal to the engine ECU;

[0035] Urea nozzle 2, the spray angle is adjustable, and the sprayed spray is just aimed at the metal carrier catalyst 3;

[0036] The metal carrier catalyst 3 is a porous structure, the inside can be heated by electricity, and the outside is connected to the vehicle power supply, and its power-on time is controlled by the engine ECU; the heating function of the metal carrier catalyst 3 is controlled by controlling the on and off of the current.

[0037] A method of using the above-mentioned urea heating device for high-efficiency SCR is as follows:

[0038] (1) Install the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com