Method for removing a separator in a waste lithium ion power battery

A power battery and lithium-ion technology, which is applied in the field of waste lithium-ion power battery recycling and processing, can solve the problems of electrode material residue and poor effect, and achieve complete decomposition, good cooling effect, and reduced time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

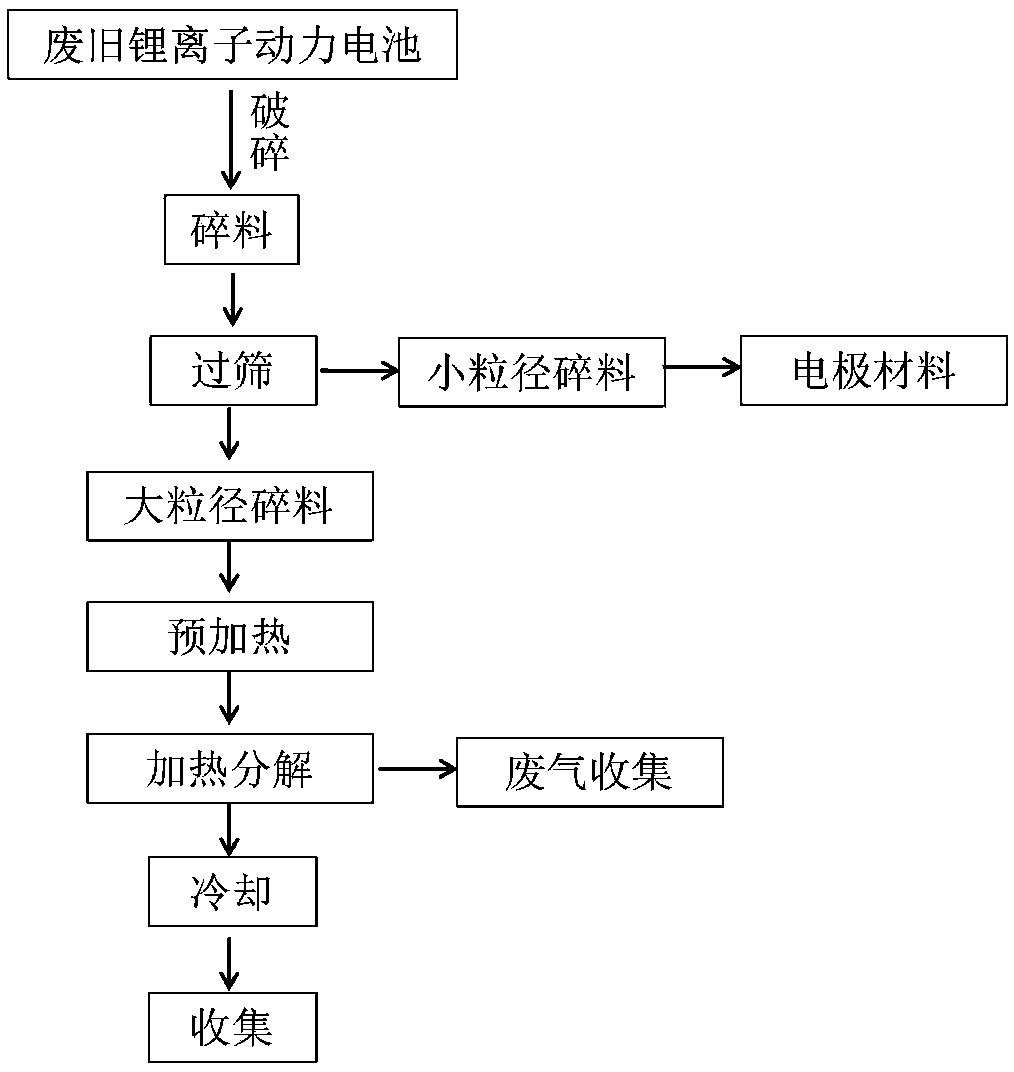

[0035] A method for removing polyolefin microporous diaphragms in waste lithium-ion power batteries of the present invention, such as figure 1 shown, including the following steps:

[0036] (1) Crushing waste lithium-ion power batteries into fragments with a diameter of no more than 15 mm and passing through a 5-mesh sieve to obtain small-grained fragments with a particle diameter of less than 5 mesh and large-grained fragments with a particle diameter greater than 5 mesh;

[0037] (2) The large-size crushed material obtained after the step (1) is transported to the rotary kiln reaction furnace of the removing device of the diaphragm by a conveyor belt for preheating, the temperature of the preheating is controlled at 150 ° C, and the preheating time is 1.0h;

[0038] (3) Continue to heat and decompose the scrap obtained after the preheating in step (2) is completed in the rotary kiln reaction furnace until the diaphragm in the scrap is completely thermally decomposed, and th...

Embodiment 2

[0043] A method for removing polyolefin microporous diaphragms in waste lithium-ion power batteries of the present invention, comprising the steps of:

[0044] (1) Crushing waste lithium-ion power batteries into fragments with a diameter of no more than 15 mm and passing through a 5-mesh sieve to obtain small-grained fragments with a particle diameter of less than 5 mesh and large-grained fragments with a particle diameter greater than 5 mesh;

[0045] (2) The large-size crushed material obtained after the step (1) is transported to the rotary kiln reaction furnace of the diaphragm removal device by a conveyor belt for preheating. The preheating temperature is controlled at 100 ° C. The preheating time is 2.0h;

[0046] (3) Continue to heat and decompose the scrap obtained after the preheating in step (2) in the rotary kiln reactor until the diaphragm in the scrap is completely thermally decomposed, and the temperature of thermal decomposition is controlled at 300°C. The time...

Embodiment 3

[0051] A method for removing polyolefin microporous diaphragms in waste lithium-ion power batteries of the present invention, comprising the steps of:

[0052] (1) Crushing waste lithium-ion power batteries into fragments with a diameter of no more than 15 mm and passing through a 5-mesh sieve to obtain small-grained fragments with a particle diameter of less than 5 mesh and large-grained fragments with a particle diameter greater than 5 mesh;

[0053] (2) The large-size crushed material obtained after the step (1) is transported to the rotary kiln reaction furnace of the diaphragm removal device by a conveyor belt for preheating. The preheating temperature is controlled at 300 ° C. The preheating time is 0.5h;

[0054] (3) Continue to heat and decompose the scrap obtained after the preheating in step (2) is completed in the rotary kiln reaction furnace until the diaphragm in the scrap is completely thermally decomposed, and the temperature of thermal decomposition is controll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com