Integrated system for pyrolysis and upgrading of coal

A complete system, coal pyrolysis technology, applied in the field of coal pyrolysis and quality improvement integrated complete system, can solve the problems of heavy dust removal workload of oil and gas products, difficult sealing of high-temperature solid materials, low process reliability, etc., to improve process reliability High reliability, reduced equipment investment, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

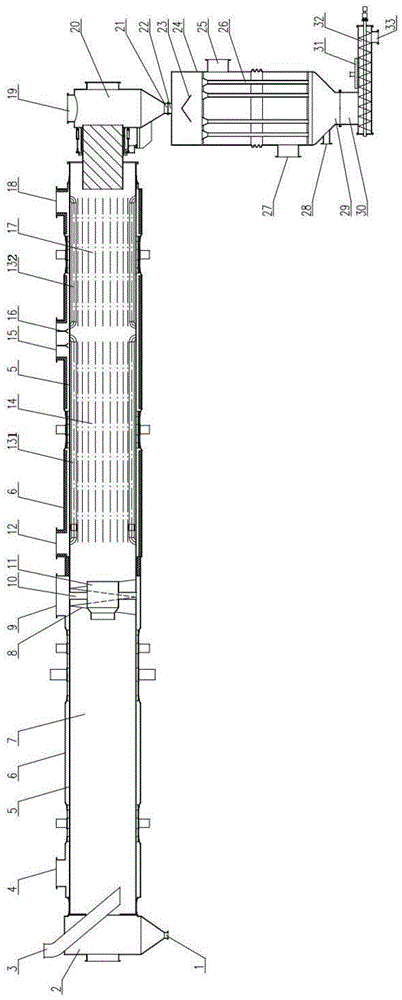

[0037] This embodiment provides a complete coal pyrolysis and upgrading integrated system, which is sequentially connected with a drying pyrolysis unit, an upgraded coal cooling unit, and a humidification and discharge unit along the process route.

[0038] The dry pyrolysis unit includes a horizontally arranged rotary cylinder 5 and an outer jacket 6 sleeved on the outside of the side wall of the rotary cylinder 5, and a smoke is formed between the rotary cylinder 5 and the outer jacket 6. Air channel; the front end of the rotary cylinder 5 is provided with a feed port, and the rear end of the rotary cylinder 5 is provided with a discharge port.

[0039] The rotary cylinder 5 along the direction of the process route includes a drying section 7, a reaction section 14 and a heat preservation section 17 in sequence. In this embodiment, along the central axis of the rotary cylinder 5, the drying section 7, the reaction section 14 And the length of the heat preservation section 17...

Embodiment 2

[0054] This embodiment provides an integrated system for coal pyrolysis and upgrading, its structure is as follows figure 1 As shown, a dry pyrolysis unit, an upgraded coal cooling unit, and a humidification and discharge unit are sequentially connected along the process route.

[0055] The dry pyrolysis unit includes a horizontally arranged rotary cylinder 5 and an outer jacket 6 sleeved on the outside of the rotary cylinder 5, and a flue gas channel is formed between the rotary cylinder 5 and the outer jacket 6 ; The front end of the rotary cylinder 5 is provided with a feed port, and the rear end of the rotary cylinder 5 is provided with a discharge port. As a preferred embodiment, in this embodiment, a feeder 3 is provided in communication with the feed port of the rotary cylinder 5, and the feeder 3 is a chute; There is an ash discharge box 2, the bottom of the ash discharge box 2 is provided with an ash discharge port 34, and the side wall of the ash discharge box 2 is ...

Embodiment 3

[0072] This embodiment provides a complete coal pyrolysis and upgrading integrated system, which is sequentially connected with a drying pyrolysis unit, an upgraded coal cooling unit, and a humidification and discharge unit along the process route.

[0073] The dry pyrolysis unit includes a horizontally arranged rotary cylinder 5 and an outer jacket 6 sleeved on the outside of the side wall of the rotary cylinder 5. Between the rotary cylinder 5 and the outer jacket 6 is a Smoke channel; the front end of the rotary cylinder 5 is provided with a material inlet, and the rear end of the rotary cylinder 5 is provided with a discharge port. As a preferred embodiment, in this embodiment, a feeder 3 is provided in communication with the feed port of the rotary cylinder 5, and the feeder 3 is a screw feeder; It is connected with an ash discharge box 2, the bottom of the ash discharge box 2 is provided with an ash discharge port 34, and the side wall of the ash discharge box 2 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com