Urea powerful mixing device for SCR system of small and medium-sized ship

A technology of SCR system and mixing device, applied in muffler device, exhaust device, engine components, etc., can solve the problems of uneven mixing of urea spray and flue gas, deviation of inlet speed of SCR catalyst, and low urea pyrolysis efficiency, etc. Achieve the effect of improving deposition phenomenon, prolonging equipment service life and improving denitration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

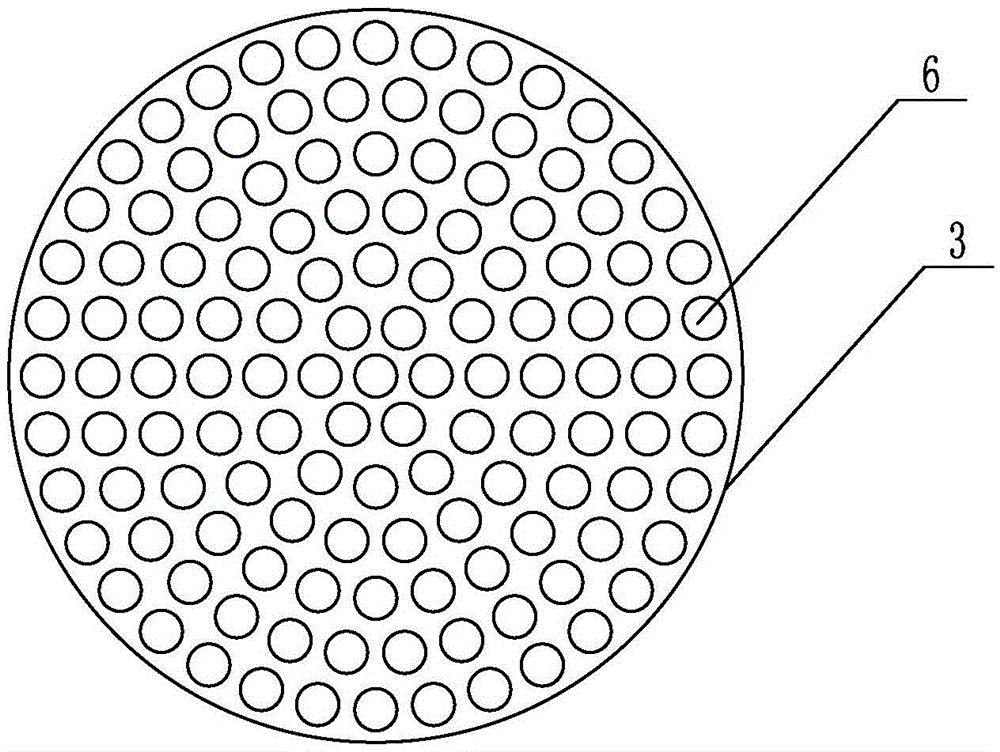

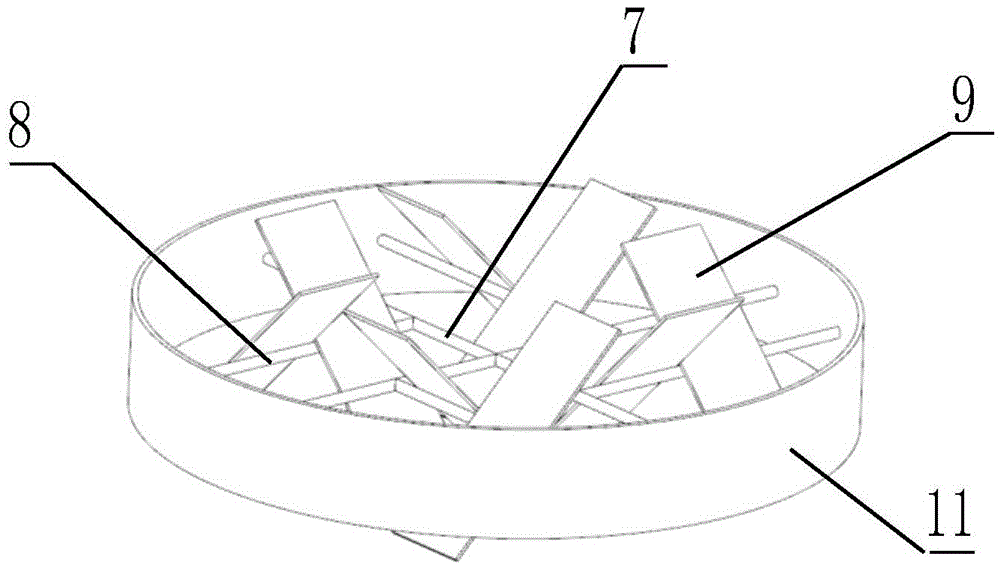

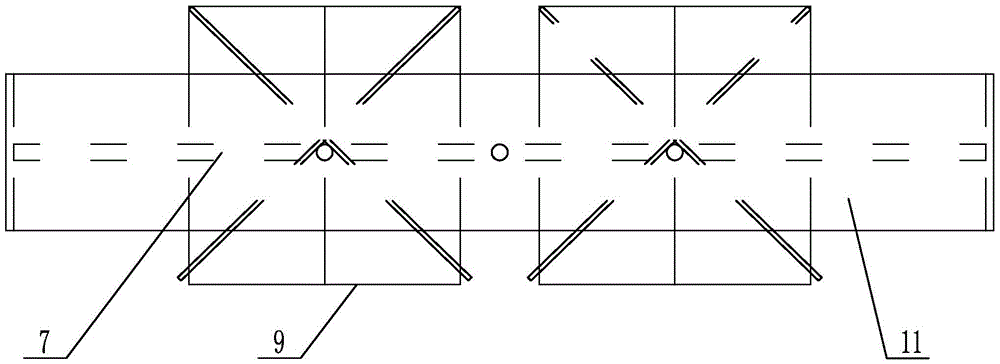

[0027] A powerful urea mixing device for small and medium-sized ship SCR systems, such as Figure 4 As shown, the device includes a pipe body and a perforated plate installed in the pipe body from bottom to top, a urea nozzle 4 and a mixer, the rectification device is a perforated plate 3 distributed with a plurality of circular holes, and the turbulent flow The device is a mixer 5, on which four cross-shaped fins are fixed, and the fins are formed by interlacing two flat plates. The perforated plate is installed 340cm upstream of the urea nozzle, and the mixer is installed 500cm downstream of the urea nozzle. The perforated plate, urea nozzle and mixer are sequentially arranged in the pipeline along the direction of flue gas flow. A connecting flange 1 for connecting with the SCR system is welded on the pipe body.

[0028] For the structure of perforated plates, see figure 1 , The perforated plate is made of a circular steel plate with a diameter of 330mm and a thickness o...

Embodiment 2

[0033] A powerful urea mixing device for small and medium-sized ship SCR systems, such as Figure 4 As shown, the device includes a pipe body and a perforated plate installed in the pipe body from bottom to top, a urea nozzle 4 and a mixer, the rectification device is a perforated plate 3 distributed with a plurality of circular holes, and the turbulent flow The device is a mixer 5, on which four cross-shaped fins are fixed, and the fins are formed by interlacing two flat plates. The perforated plate is installed 200cm upstream of the urea nozzle, and the mixer is installed 300cm downstream of the urea nozzle. The perforated plate, urea nozzle and mixer are sequentially arranged in the pipeline along the direction of flue gas flow. A connecting flange 1 for connecting with the SCR system is welded on the pipe body.

[0034] For the structure of perforated plates, see figure 1 , The perforated plate is made of a circular steel plate with a diameter of 300mm and a thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com