Small-size oil shale dry distillation system heated based on heat accumulation type gas radiation pipe

A radiant tube heating and small particle technology, which is applied in the field of oil shale carbonization, can solve the problems of unutilized latent heat, low operation rate, and shutdown for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

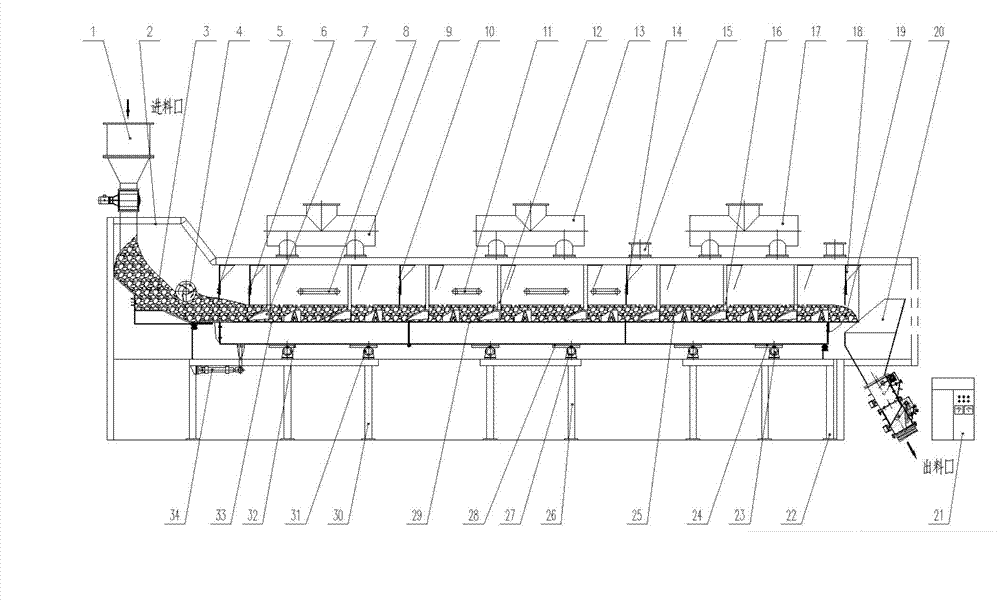

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Referring to the accompanying drawings, a small-particle oil shale retort system based on regenerative gas radiant tube heating includes a shell 2, and the inside of the shell 2 is divided into a drying section, a dry distillation section, and a waste heat recovery section that communicate with each other. The shell 2 It is a material heating channel with an all-metal shell lined with high-grade refractory materials to ensure the sealing and heat preservation of the furnace body. The front end of the casing 2 is equipped with a feeding device 1. The oil shale material 3 enters the interior of the casing 2 through the feeding device 1 and falls onto the conveying assembly 33 of the drying section. The conveying assembly 33 of the drying section is equipped with a material distribution device 4 and a material height The control device 5, the feeding device 1 ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com