Ammonium bicarbonate direct injection denitration reduction system and method

A technology of ammonium bicarbonate and ammonium bicarbonate solution is applied in the field of flue gas denitrification treatment, which can solve the problems of easy blockage of the system, safety risks of ammonium bicarbonate solution, low operation and maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

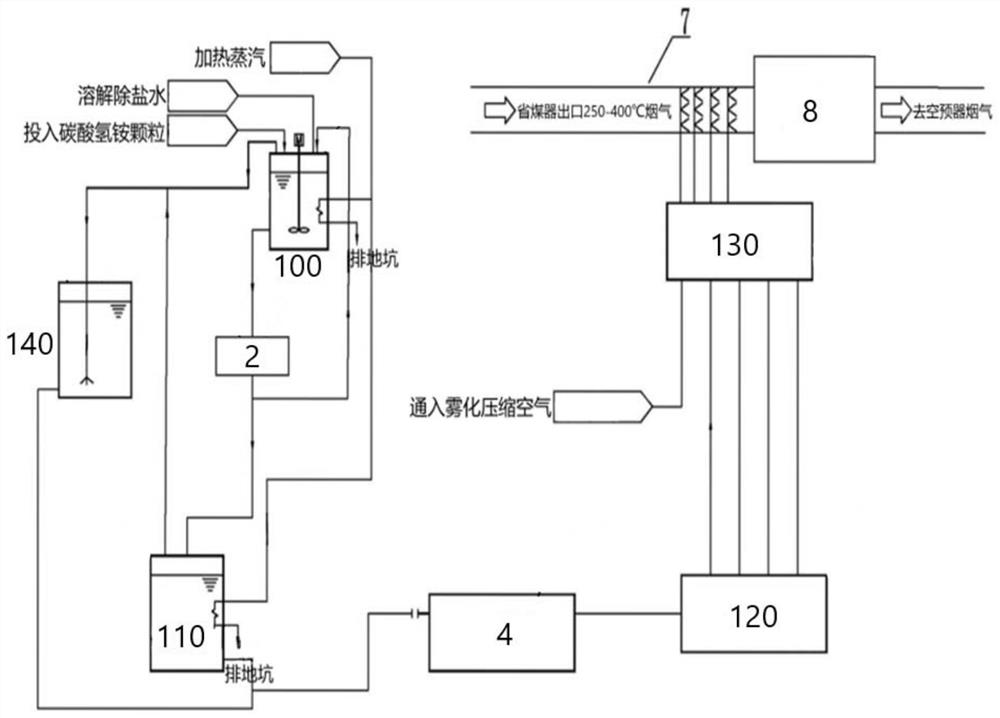

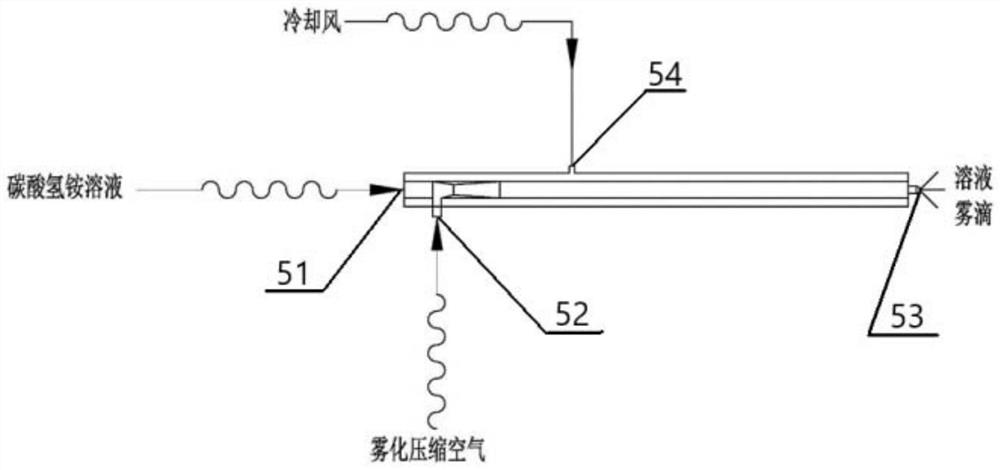

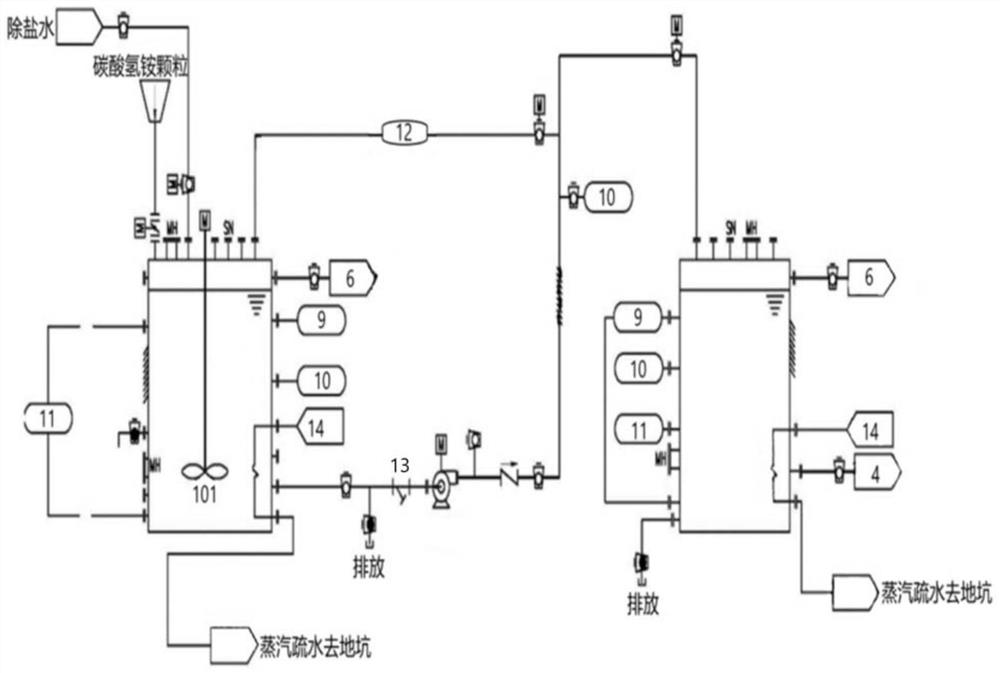

[0047] A kind of ammonium bicarbonate direct injection denitrification reduction system, such as figure 1 As shown, it includes sequentially connected ammonium bicarbonate dissolving device 100, ammonium bicarbonate solution storage device 110, metering distribution module 120, injection device 130 and SCR denitration reactor 8; comprises a plurality of parallel injectors 5, such as figure 2 As shown, the output end of each injector 5 is provided with a nozzle 53, the input end is provided with an ammonium bicarbonate solution inlet 51, and one side of the ammonium bicarbonate solution inlet 51 is provided with a connected atomized compressed air inlet 52, and the injector 5 is arranged along the smoke The gas direction is set in the inlet flue 7 of the SCR denitrification reactor 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com