Hydrogenation reaction ammonium salt crystallization prevention device

A hydrogenation reaction and crystallization device technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the prominent problems of system pressure drop rise, heat exchange efficiency reduction, and ammonium salt crystallization and other problems to achieve the effect of reducing load, improving heat exchange efficiency and solving the problem of ammonium salt crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

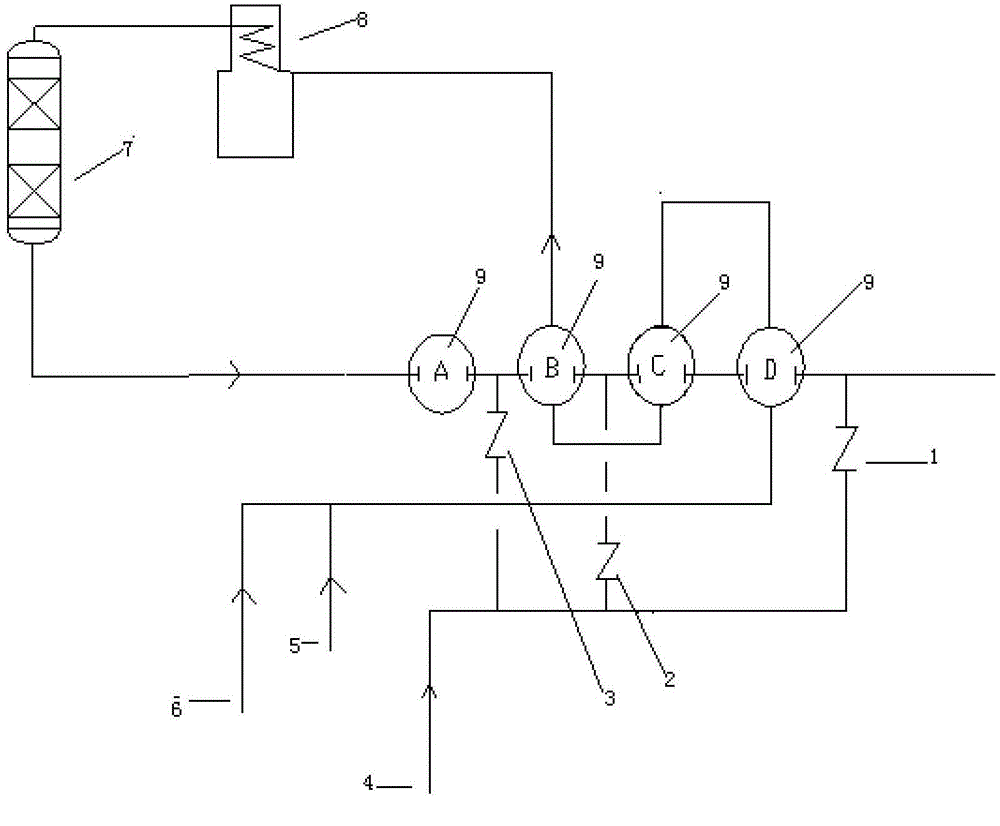

[0017] Such as figure 1 As shown, in the lower part of the device, a feed oil inlet 6 and a new hydrogen inlet 5 connected in parallel are provided, and the water injection point 1 and the water injection point supplied by the water injection line 4 are inserted between the heat exchangers A / B / C / D9 respectively. 2 and water injection point 3, the water injection temperature is controlled between the ammonium salt crystallization point and the water dew point, and the water injection volume is controlled at a ratio greater than 5.2% to the raw oil. In the traditional process, as the reaction proceeds, ammonium salt crystallization precipitates and accumulates in the heat exchanger A / B / C / D9, causing blockage. When the circulating hydrogen flow rate decreases and the temperature rises, the consequences will increase the crystallization precipitation and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com