Urea supply injection system with two-stage injection function

A two-stage injection and injection system technology, applied in mechanical equipment, exhaust treatment, engine components, etc., can solve the problem of inability to treat exhaust gas, achieve excellent urea atomization performance, reduce device costs, and prevent crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

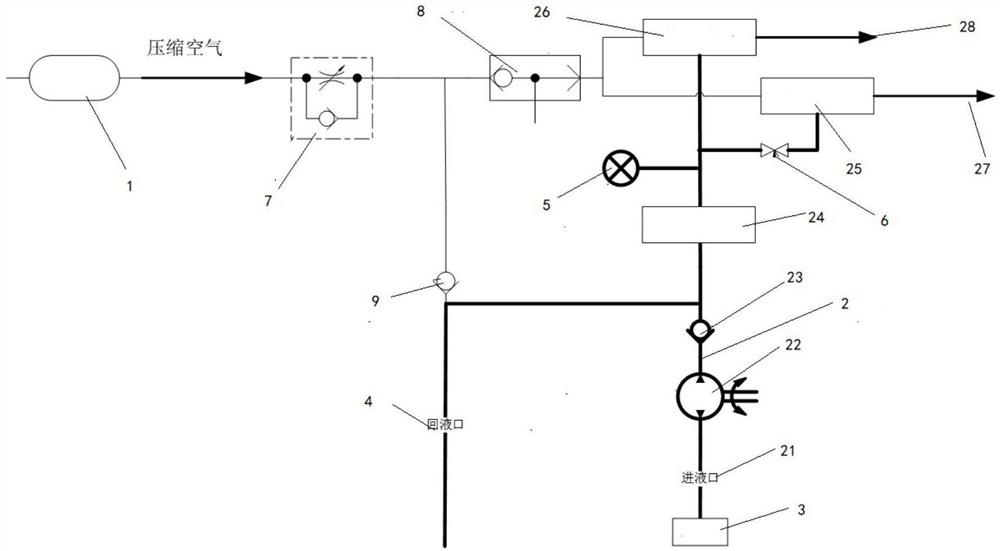

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] The technical scheme adopted in the present invention is:

[0025] A urea supply injection system with dual-stage injection function, comprising a gas tank 1, a throttle valve 7 is provided at the outlet of the gas tank 1, and a gas circuit check valve 8 is provided at the outlet of the throttle valve 7, and the throttle valve 7 is connected with the There is also a check valve 9 connected to the liquid return port 4 between the gas circuit check valves 8, and the other circuit is a liquid circuit device 2, which includes a liquid inlet 21, and the liquid inlet 21 is also provided with a The filter screen 3, the urea pump 22 connected to the liquid inlet 21, the liquid path check valve 23 connected to the urea pump 22, the pressure stabilizing chamber 24 connected to the liquid path check valve 23, and the outlet of the stabilizing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com