Method for preparing anhydrous sodium sulphate from mirabilite hydrate in chlor-alkali production and related nitre melting equipment

A technology of sodium sodium sulfate and Glauber's salt, which is applied in the dehydration processing field of Glauber's salt decahydrate, can solve the problems of unsalable Glauber's salt decahydrate, difficult operation, blockage, start-up and shutdown, etc., and achieve low equipment manufacturing costs, poor material corrosion, and device operation stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

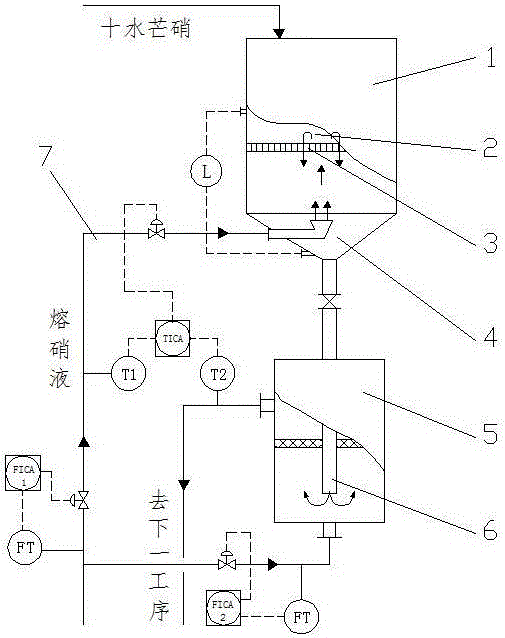

[0058] Embodiment 1 (melting nitrification equipment)

[0059] as attached figure 1 As shown, in a kind of chlor-alkali production of the present invention, the melting nitrification equipment involved in the dehydration of mirabilis decahydrate to make Yuanming powder includes: melting nitric acid tank 1, melter 5 and molten nitric liquid pipeline 7, which are located in the melting nitric tank The grid 3 in 1 divides its inner cavity into a solid phase area 4 and a melting area 2, and the solid phase area 4 is located above the melting area 2, Glauber's salt decahydrate is accumulated in the solid phase area 4, and the melting furnace flows through the nitric acid slurry Passage 6 communicates with the bottom of melting zone 2, and the molten nitric liquid pipeline 7 is divided into two ways:

[0060] One of them enters the melting zone 2, contacts with the Glauber's salt decahydrate accumulated in the solid phase zone 4 from bottom to top, and melts at the solid-liquid con...

Embodiment 2

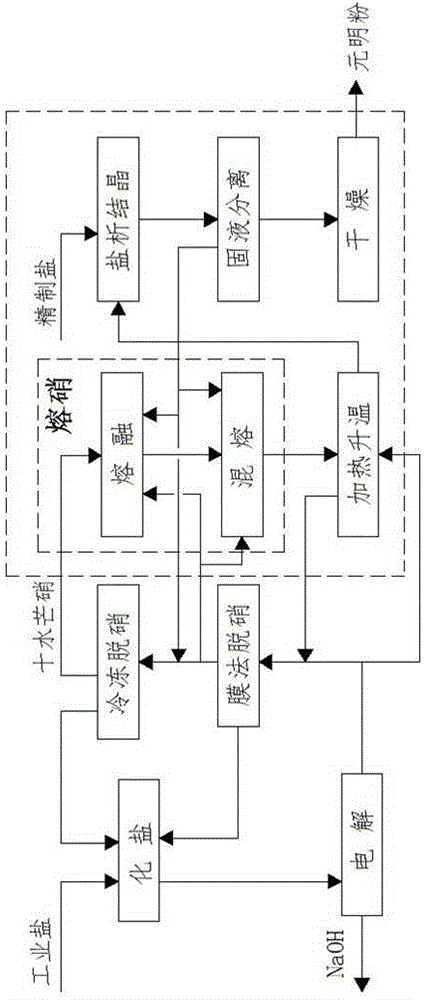

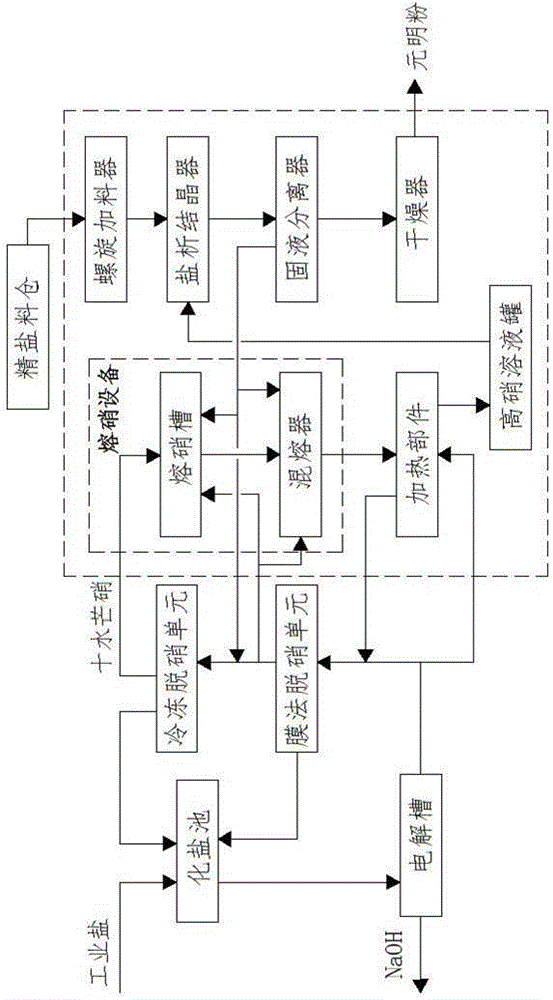

[0065] Embodiment 2 (device for dehydration of Glauber's salt decahydrate in chlor-alkali production)

[0066] as attached figure 1 , 3 As shown, a kind of device of the dehydration system sodium sodium decahydrate Glauber's salt in a kind of chlor-alkali production of the present invention comprises:

[0067] Nitrate melting unit: based on the melting nitrification equipment of Embodiment 1, it is used to melt Glauber's salt decahydrate first and then mix and melt it under the condition of adding molten nitric acid liquid, to form a solid-containing high-nitrate solution with part of sodium sulfate precipitated;

[0068] Heating unit: it includes a heating part and a high-nitrate solution tank. The heating part heats up and controls the temperature of the solid-containing high-nitrate solution at the outlet of the melting nitrification equipment to form a high-nitrate solution and store it in the high-nitrate solution tank:

[0069] Salting out crystallizer: used to receive...

Embodiment 3

[0077] Embodiment 3 (method for dehydration of Glauber's salt decahydrate in chlor-alkali production)

[0078] as attached figure 1 , 2 As shown, a method for dehydrating Glauber's salt decahydrate in the production of chlor-alkali of the present invention to prepare sodium salt, the method is to melt the Glauber's salt decahydrate separated by membrane denitrification, heat up to obtain a high-nitrate solution, and then salt out Crystallization, solid-liquid separation, and drying to obtain Yuanming powder specifically include the following steps:

[0079] a. Molten nitrification: The melting nitrification process is based on the melting nitrification equipment of Embodiment 1. The melting nitrification includes the following steps: ① Heaping the decahydrate Glauber’s salt from the lifting equipment to the solid phase zone 4 of the melting nitrification tank 1; ② 40°C molten nitric acid liquid Divided into two paths with a flow rate of 2.5 m³ / h: one path is injected into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com