Construction methods of hanging beam and assembling cantilever in the bottom of steel case beam

A construction method and technology of steel box girders, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as unrealistic, large steel consumption, unfavorable shipping, etc., and achieve the effect of less equipment, saving man-hours, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

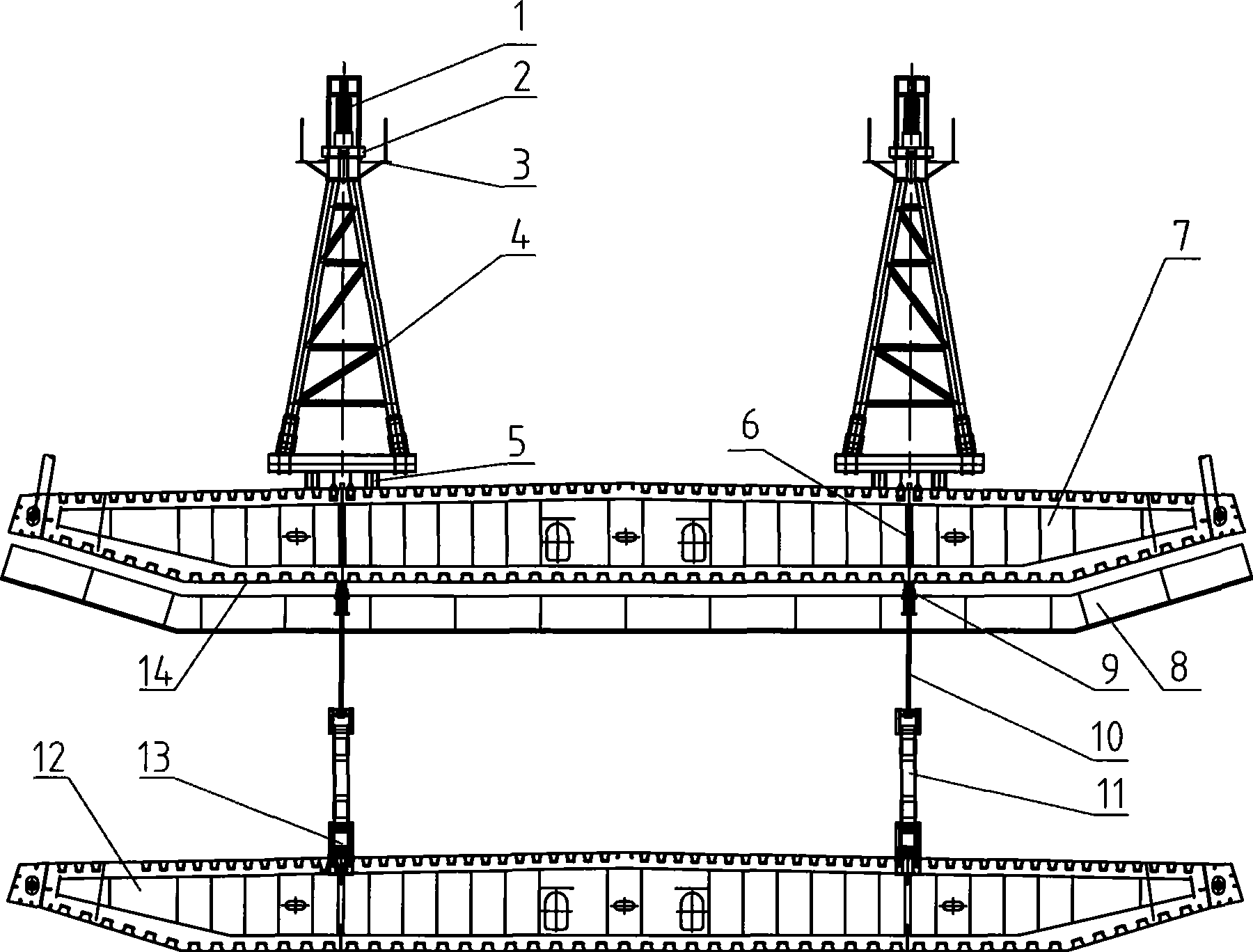

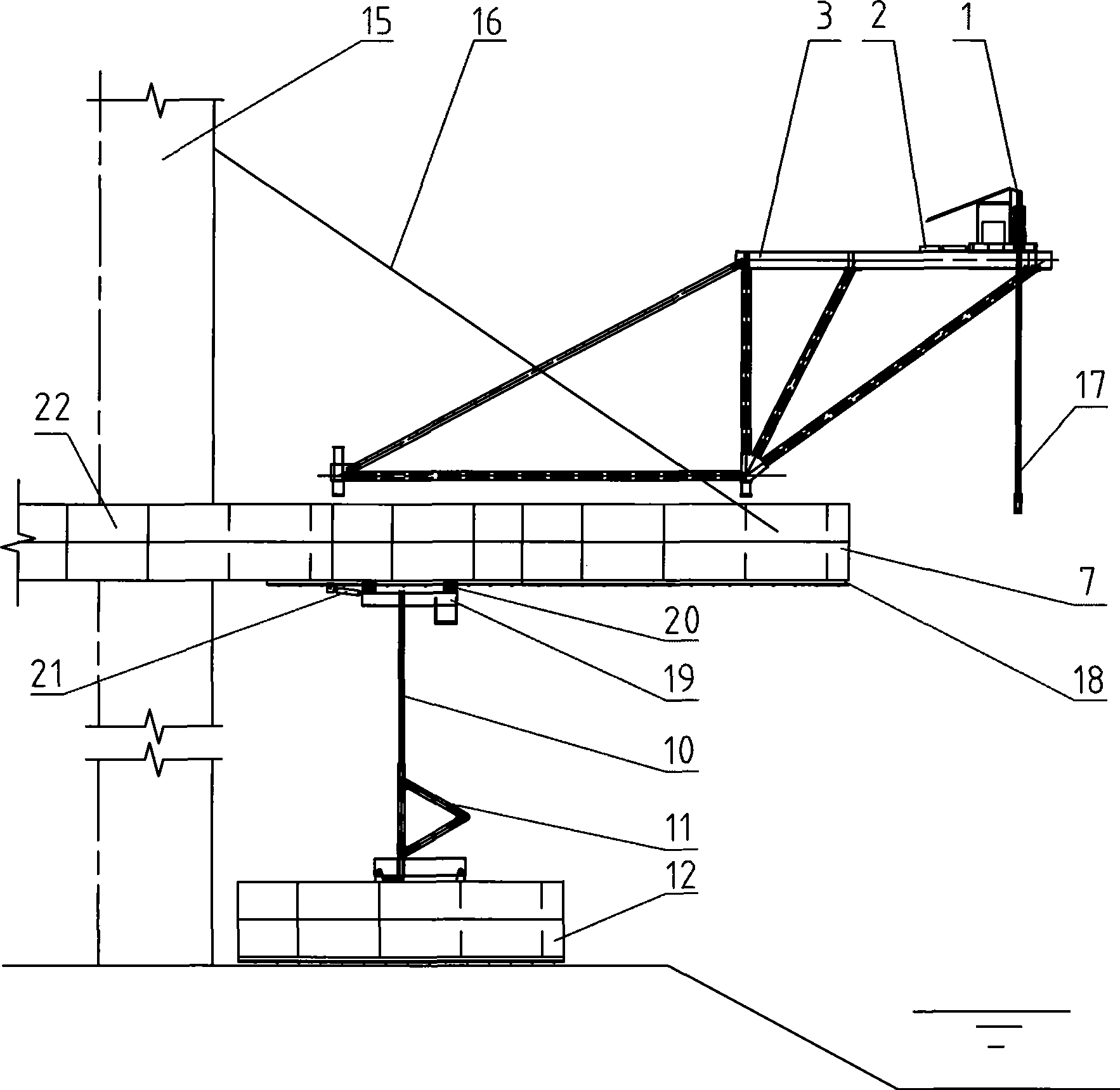

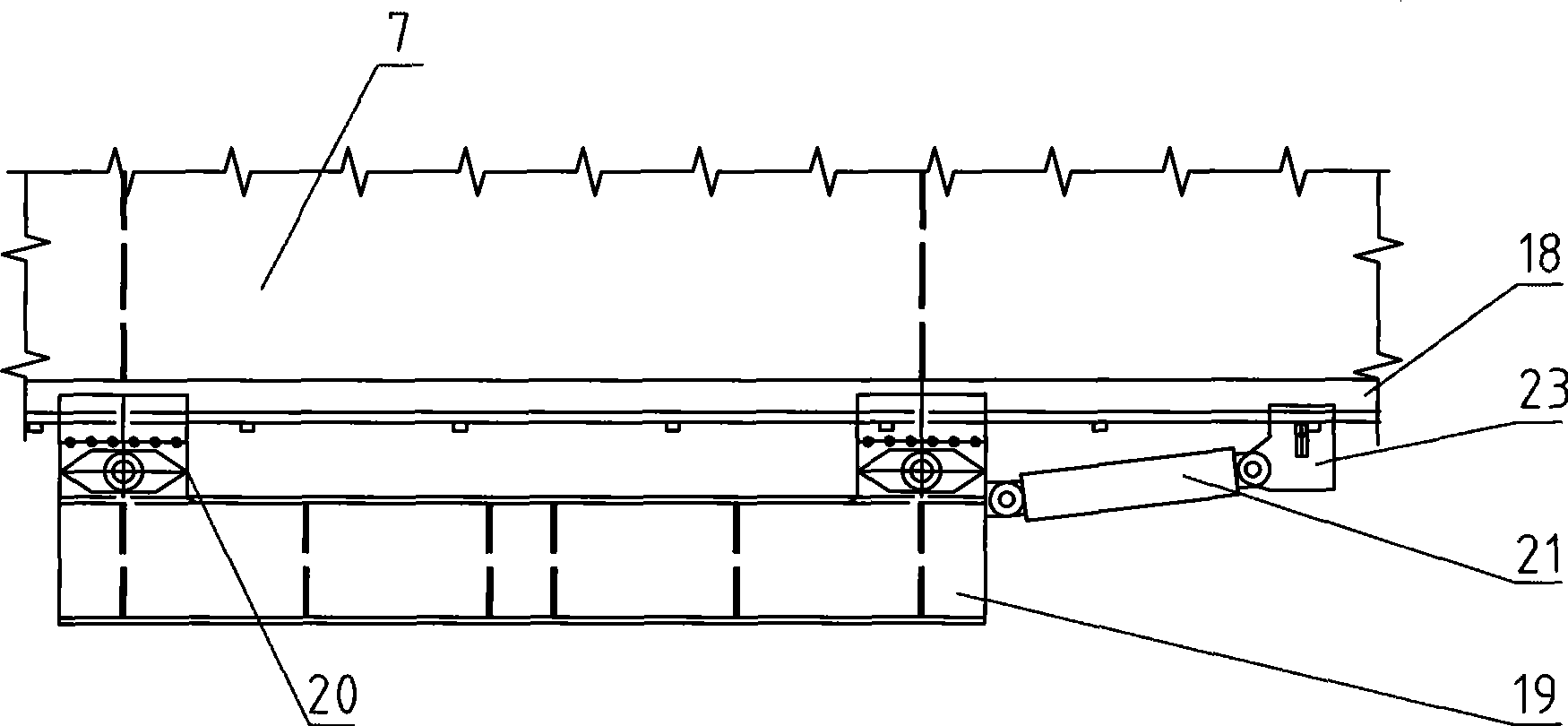

[0040] Now refer to the attached Figures 1 to 9 To clarify selected embodiments of the present invention, the following descriptions of the embodiments of the present invention according to the present disclosure by those skilled in the art are only exemplary, and are not intended to limit the solutions of the present invention.

[0041] In this embodiment, the steel box girder girder is suspended at the bottom of the girder, and the cantilever assembly construction method includes the construction of the cable tower 15 and the steps of installing the initial section of the steel box girder 22 at the beam of the cable tower, and the bridge deck formed by the steel box girder. In the step of setting up the bridge deck crane 4 with cantilever, when the steel box girder is prefabricated, the inverted T-shaped guide rail 18 is preset under the lower floor 14 corresponding to the two longitudinal partitions 6, and the preset slides on the inverted T-shaped guide rail. Sliding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com