SCR urea mixer for diesel internal combustion engine aftertreatment system

A diesel internal combustion engine and mixer technology, applied in the field of environmental treatment, can solve problems such as uneven mixing of hot exhaust gas, blockage of SCR catalytic converter, etc., and achieve the effect of solving urea deposition and crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0028] In conjunction with the accompanying drawings.

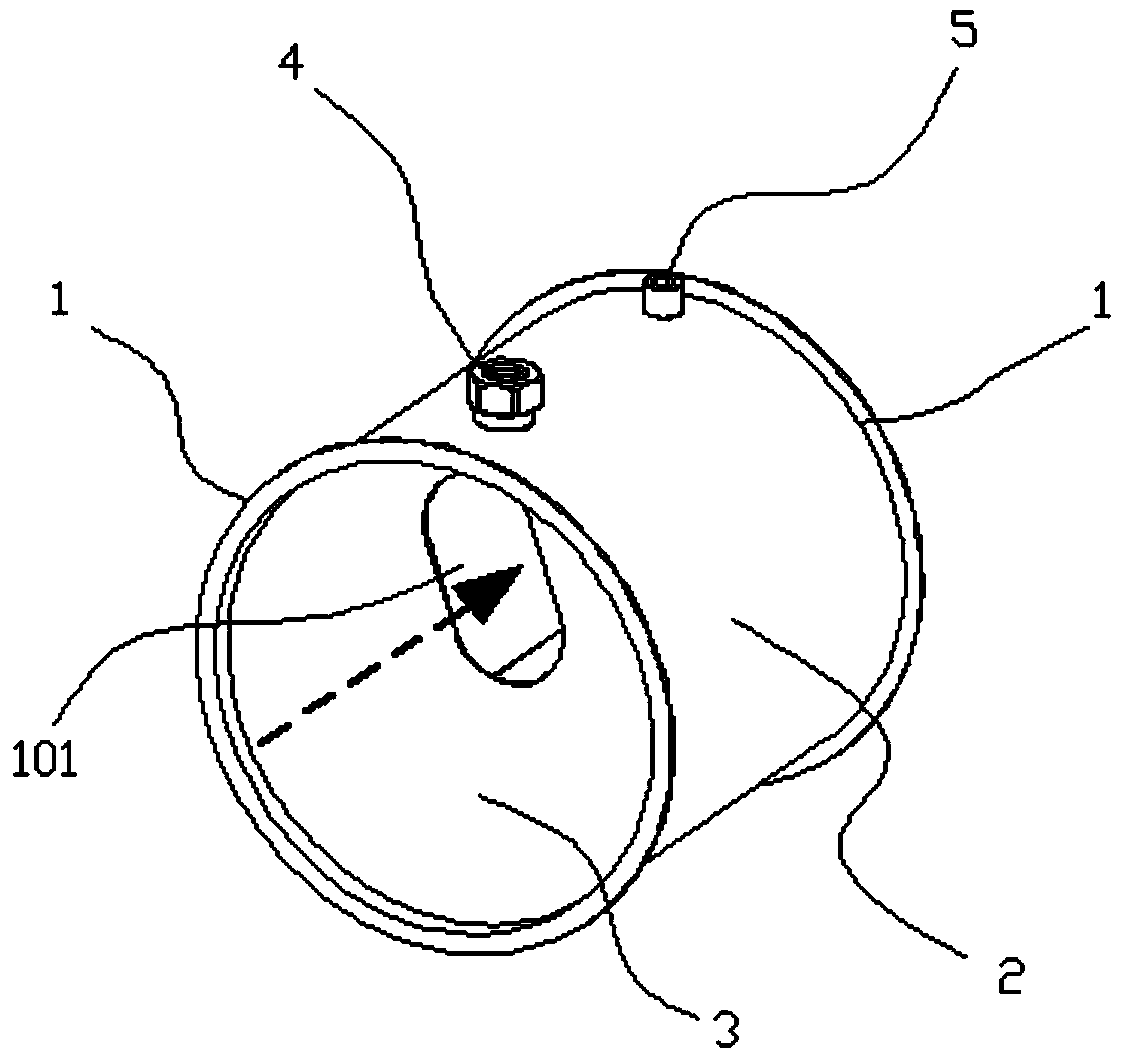

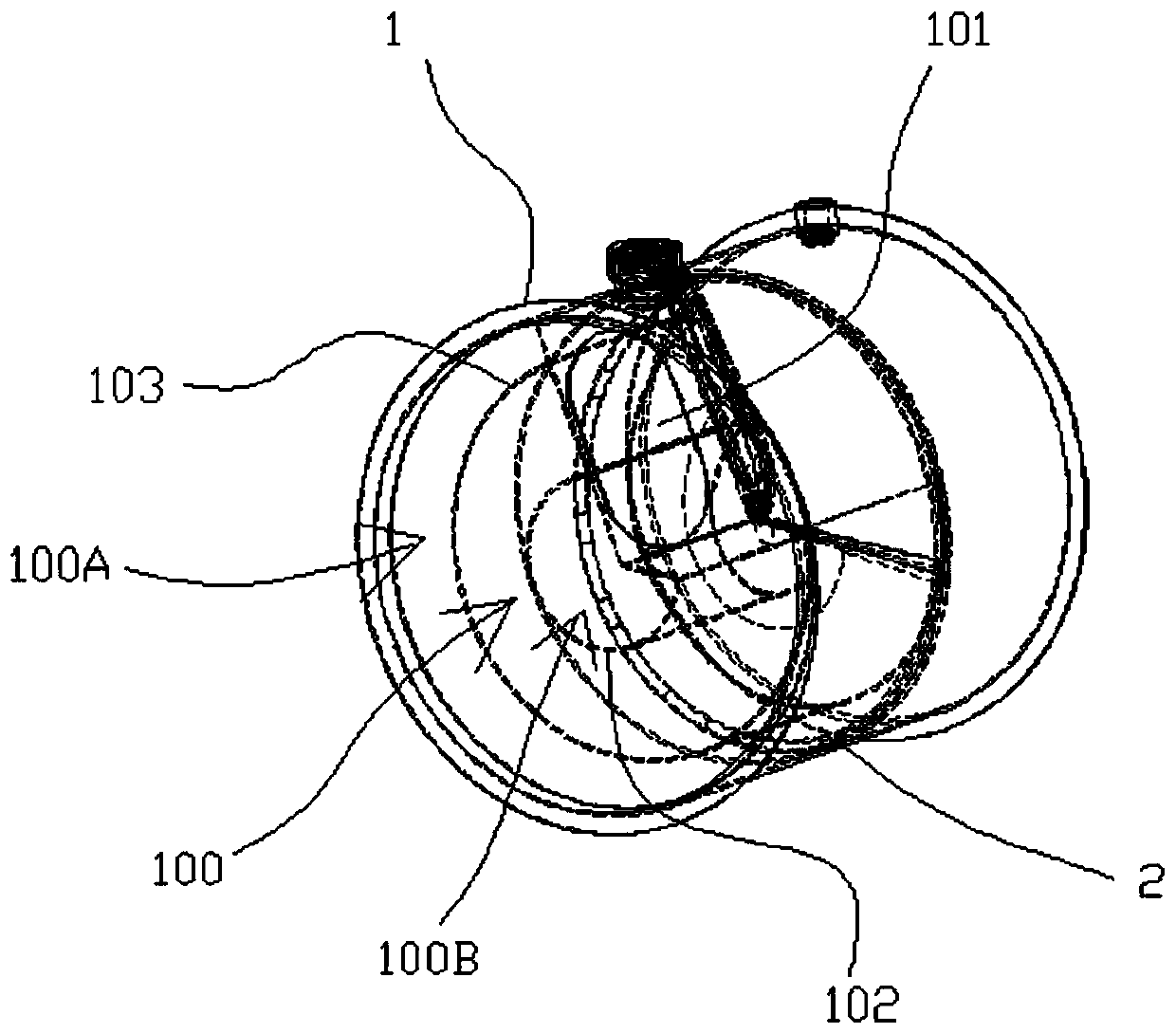

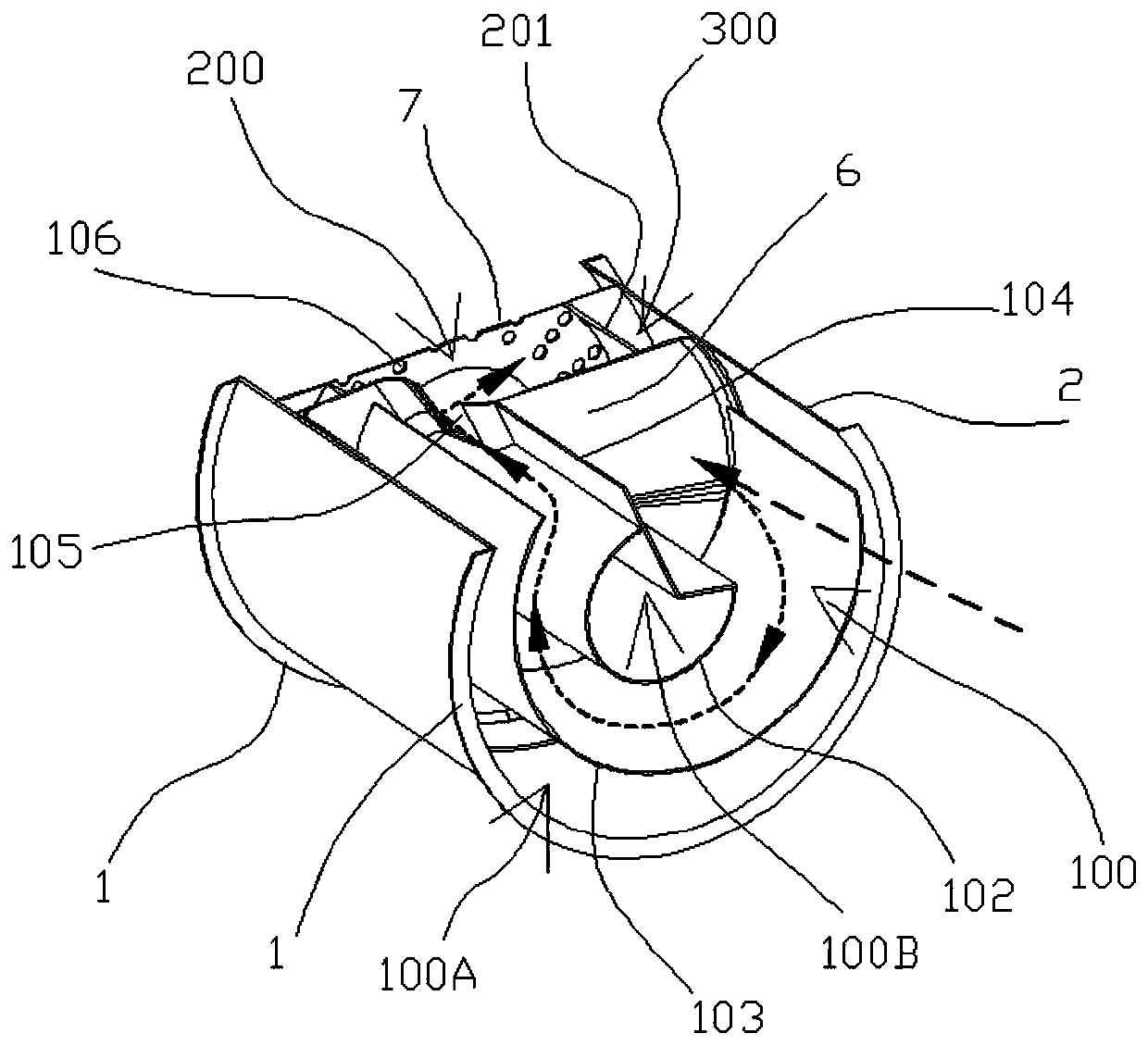

[0029] The SCR urea mixer for the diesel engine exhaust aftertreatment system includes a cylindrical shell 2 and a urea nozzle seat located on the shell. The inlet end of the mixer has three independent and isolated chambers from the inner wall of the shell to the center. They are the heat-sealed isolation chamber 100A at the intake end, the vortex mixing chamber 100, and the central sealing chamber 100B at the intake end; the exhaust end of the mixer has two independent and isolated chambers, which are the exhaust mixing chamber 200 and the exhaust mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com