Gas distribution device used for slurry bed reactor and slurry bed reactor

A gas distribution device and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of solid particle deposition, shutdown, poor gas uniform distribution effect, etc., and achieve the effect of solving deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

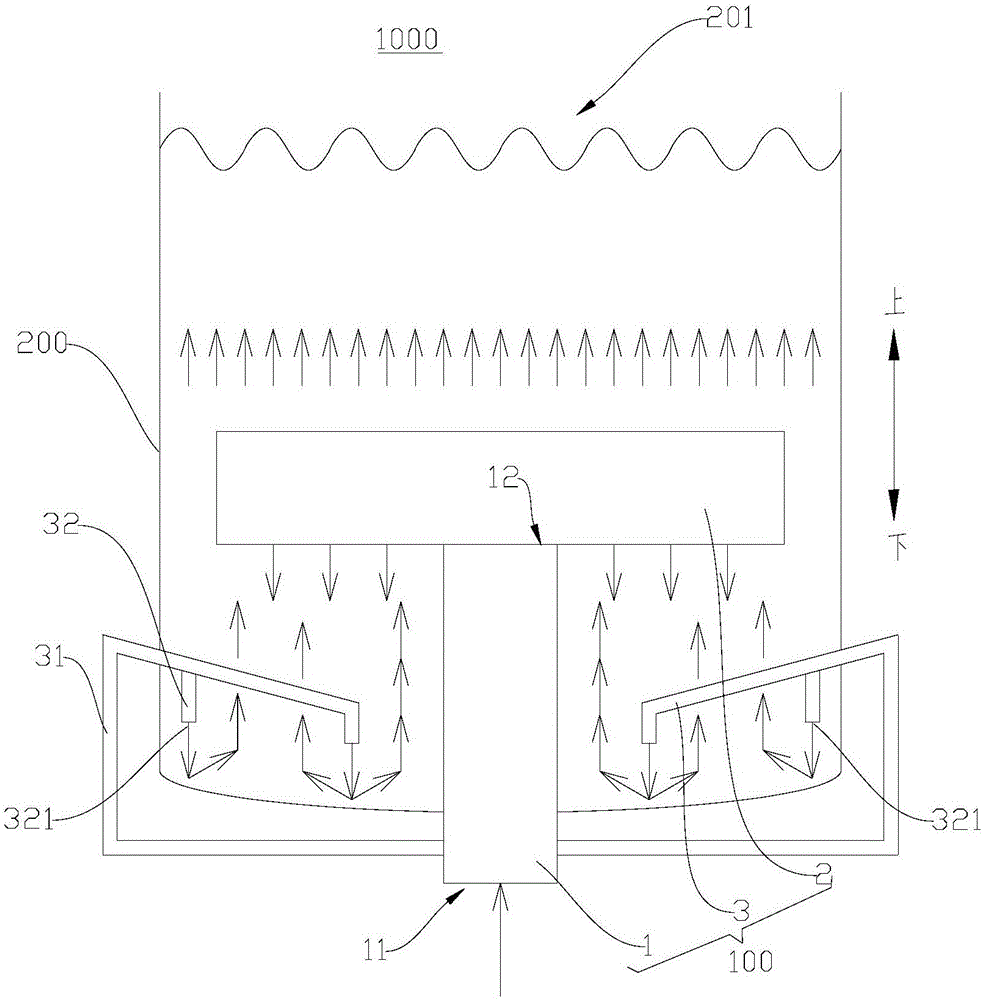

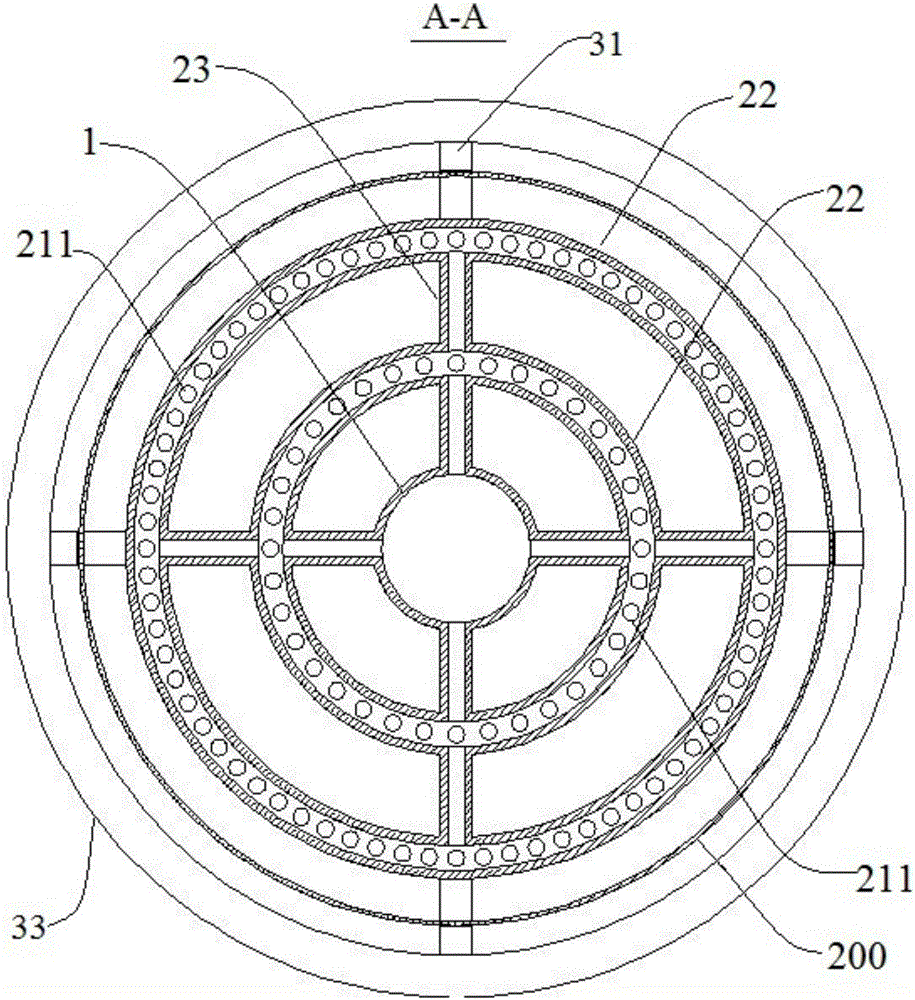

[0065] Such as Figure 2-Figure 5 As shown, the slurry bed reactor 1000 according to the embodiment of the present invention includes a kettle body 200 and a gas distribution device 100 . Wherein, the gas distribution device 100 is partly set in the kettle body 200 , the kettle body 200 contains the liquid-solid mixture, and the top wall of the kettle body 200 is provided with an exhaust port 201 . The kettle body 200 is formed in a cylindrical shape with an inner diameter of 500 mm. The slurry-bed reactor 1000 in this embodiment is a slurry-bed reactor 1000 for hydrogenating acetylene to produce ethylene.

[0066] The gas distribution device 100 includes an air inlet pipe 1 , a distribution member 2 and a spoiler 3 .

[0067] Specifically, the air inlet pipe 1 has an air inlet 11 and an air outlet 12. The air inlet pipe 1 extends into the kettle body 200 from the bottom wall of the kettle body 200 and is arranged coaxially with the kettle body 200. The air inlet 11 is locat...

Embodiment 2

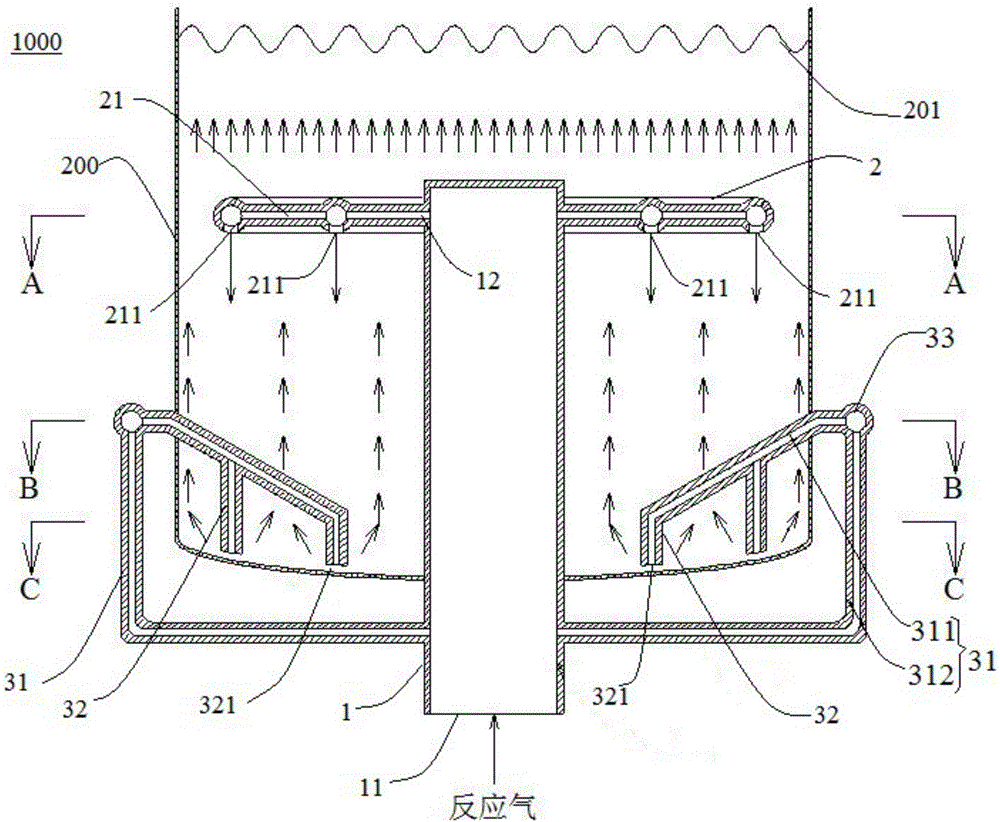

[0074] Such as Figure 6-Figure 7 As shown, the slurry bed reactor 1000 according to the embodiment of the present invention includes a kettle body 200 and a gas distribution device 100 . Wherein, the gas distribution device 100 is partly set in the kettle body 200 , the kettle body 200 contains the liquid-solid mixture, and the top wall of the kettle body 200 is provided with an exhaust port 201 . The kettle body 200 is formed in a cylindrical shape with an inner diameter of 500 mm. The slurry-bed reactor 1000 in this embodiment is a slurry-bed reactor 1000 for hydrogenating acetylene to produce ethylene.

[0075] The gas distribution device 100 includes an air inlet pipe 1 , a distribution member 2 and a spoiler 3 .

[0076] Specifically, the air inlet pipe 1 has an air inlet 11 and an air outlet 12. The air inlet pipe 1 extends into the kettle body 200 from the bottom wall of the kettle body 200 and is arranged coaxially with the kettle body 200. The air inlet 11 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com