Boiler structure for artificial board production

A technology for wood-based panels and boilers, which is applied in the treatment of combustion products, combustion methods, exhaust gas devices, etc., and can solve the problems of high risk factor, affecting production, and difficulty in cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments to make those skilled in the art with reference to the specification. Obviously, the described embodiments are merely the embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

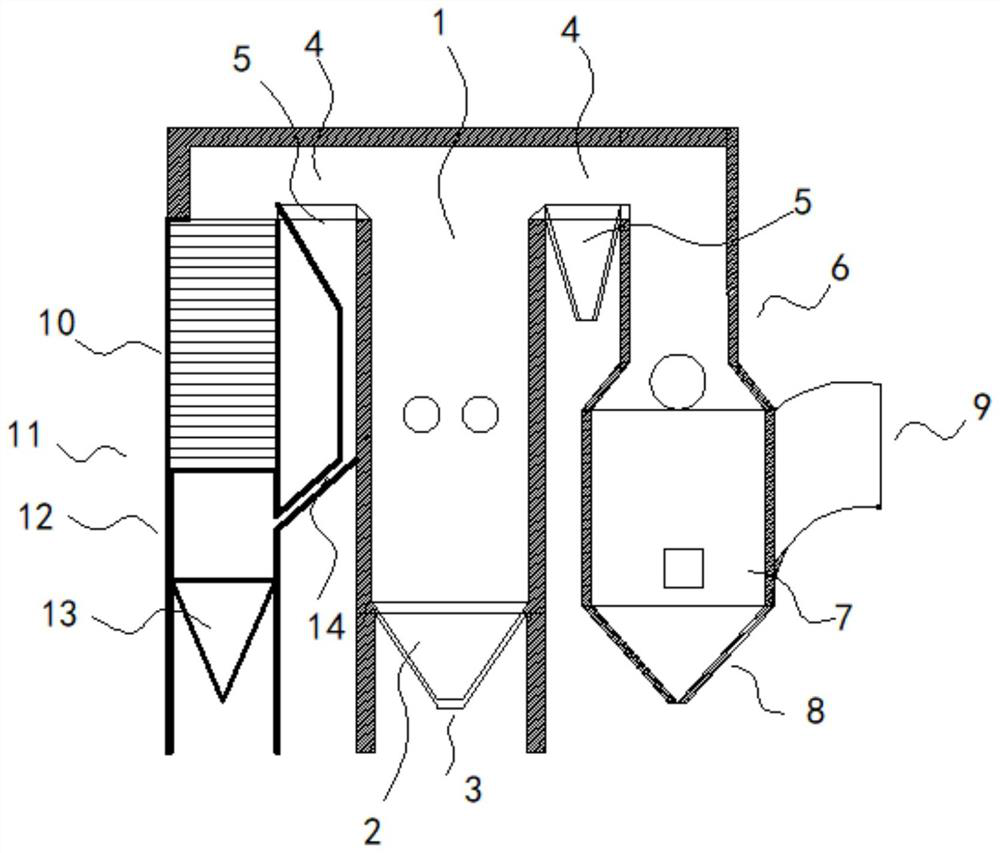

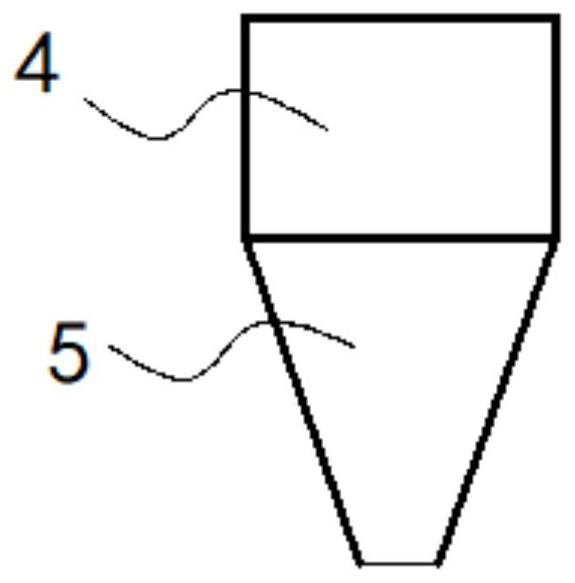

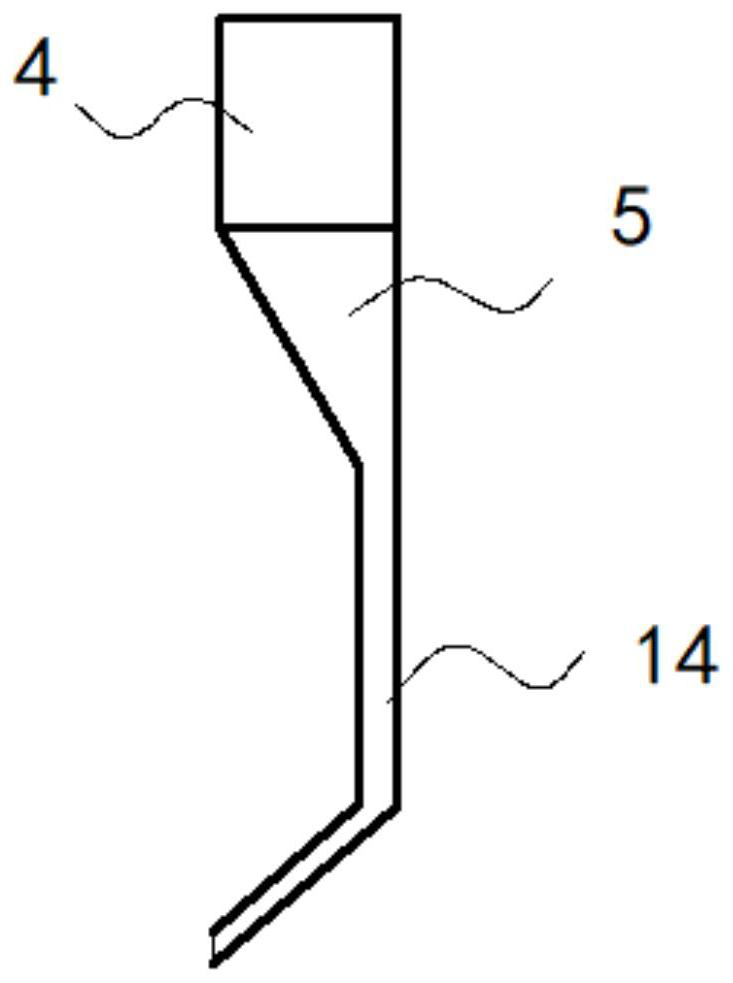

[0028] figure 1 One embodiment of the boiler structure for producing the human panel of the present invention is shown, including the boiler body 1 and a flue gas pipe 4 leading to each application direction, the application direction including at least a dry direction, figure 1 In the structure shown, the right side is the drying application direction, and the flue gas pipe 4 is opened such that the space of the flue gas pipe 4 becomes large, so that the soot is deposited here, and is ash Walk away.

[0029] The present embodiment can solve the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com