Sulfur dispersion stabilizer to prevent sulfur blocking of sulfur-evolving wellhead

A technology of dispersing stabilizer and sulfur, which is applied in wellbore/well components, drilling compositions, cleaning tools, etc., which can solve the problems of strong irritation, high price, and large dosage, so as to reduce surface tension and reduce cleaning Effects of cycle, prevention of aggregation and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 indoor test

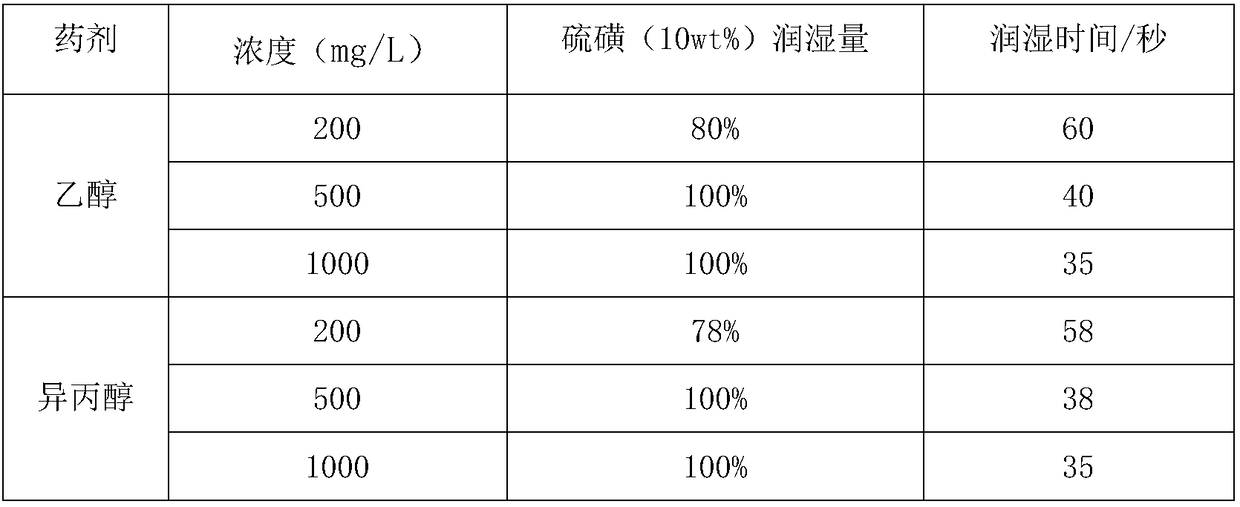

[0017] First prepare ethanol and isopropanol aqueous solutions with concentrations of 200, 500, and 1000mg / L respectively, add 10wt% sulfur, observe the wetting speed and degree of sulfur in water, and the results are as follows:

[0018] Table 1 The wetting effect of ethanol and isopropanol on sulfur

[0019]

[0020] Comparing the wetting effect of ethanol and isopropanol on sulfur, as the amount of alcohol increases, the amount of sulfur wetting increases. When the amount is greater than 500mg / L, sulfur can be wetted by 100%, and the wetting time becomes shorter as the amount of alcohol increases. , The wetting time is 35-40 seconds when it is greater than 500mg / L. Ethanol and isopropanol have the same wetting effect on sulfur, so ethanol is selected as the wetting agent for the following experiments.

[0021] Prepare an aqueous ethanol solution with a concentration of 500mg / L, then add polyacrylamide to the aqueous ethanol solution, a...

Embodiment 2

[0024] Well P3011 in Puguang Gas Field has a gas volume of 200,000 cubic meters per day and a hydrogen sulfide content of 8%. The mist catcher of the acid separation separator will be blocked in about 4 months on average under production conditions. By adding sulfur dispersant containing 500mg / L ethanol and 1g / L polyacrylamide polymer, it can be observed that under the action of sulfur dispersant, the surface tension of elemental sulfur is reduced, and water and sulfur form a homogeneous phase The mixed system reduces the adhesion and deposition characteristics of sulfur, and the sulfur particles are separated from the water by centrifugal separation, thereby reducing the deposition and clogging of sulfur. By adding sulfur dispersion stabilizer to the system, the time to clean up the clogging is shortened from 3 Once a month becomes every 4 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com